Finding the right bag manufacturer can save you time, money, and headaches. Here’s how to make an informed choice:

- Define Your Needs: Specify the type of bag, materials, quality standards, and budget. Decide between custom designs (OEM) or pre-designed options (ODM).

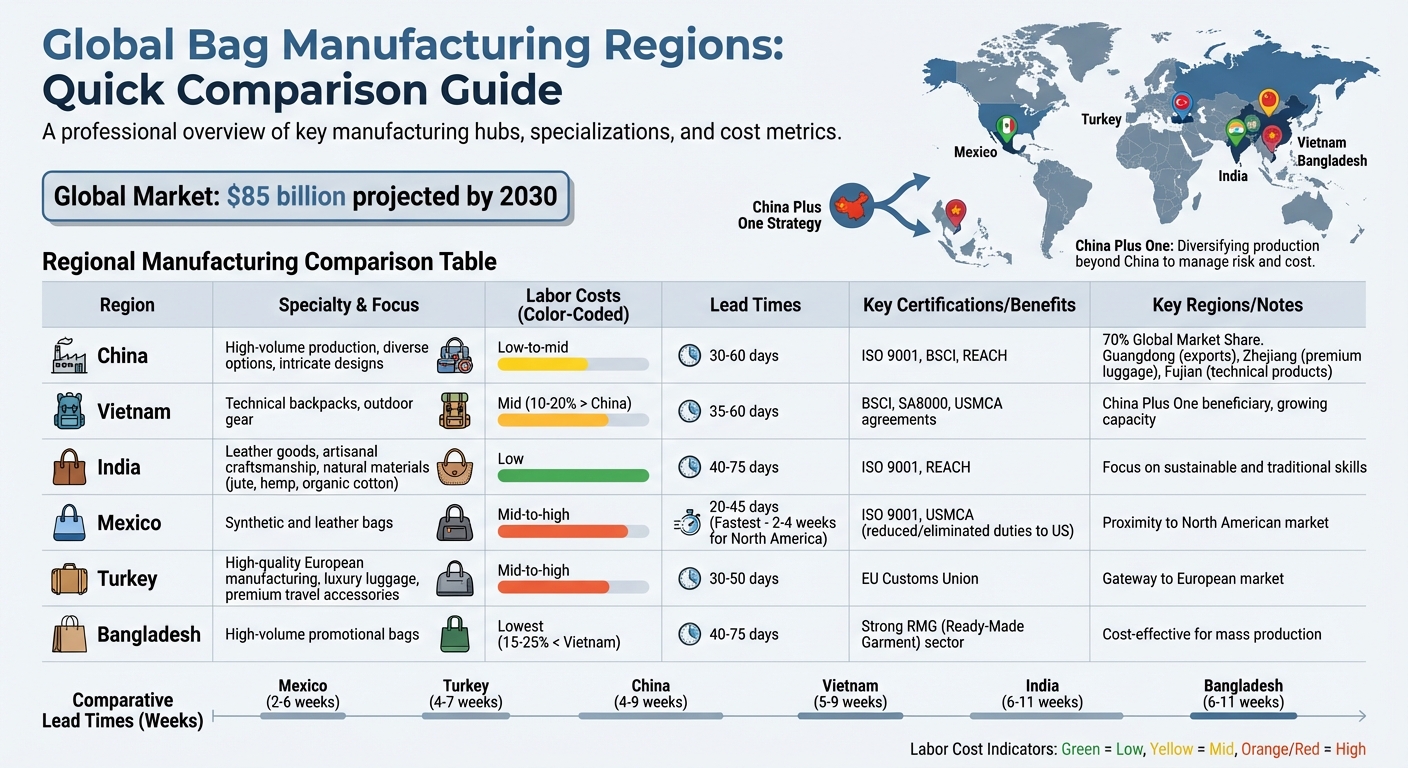

- Research Regions: China dominates global production, Vietnam excels in technical bags, and India is known for leather craftsmanship. Consider labor costs, production speed, and trade agreements.

- Assess Quality Controls: Look for manufacturers with strong inspection processes (IQC, IPQC, FQC) and certifications like ISO 9001 or REACH.

- Compare Costs and MOQs: Balance unit prices with minimum order quantities (MOQs) and shipping expenses.

- Request Samples: Test physical samples for durability, stitching, and material quality before committing to bulk production.

Quick Comparison (if applicable):

| Region | Specialty | Labor Costs | Lead Times | Certifications |

|---|---|---|---|---|

| China | High-volume, diverse options | Low-to-mid | 30–60 days | ISO 9001, BSCI, REACH |

| Vietnam | Technical backpacks, outdoor gear | Mid | 35–60 days | BSCI, SA8000 |

| India | Leather, artisanal bags | Low | 40–75 days | ISO 9001, REACH |

| Mexico | Synthetic, leather bags | Mid-to-high | 20–45 days | ISO 9001 |

Start by aligning your requirements with the strengths of each region and manufacturer to ensure consistent quality and reliable delivery.

Global Bag Manufacturing Regions Comparison: Costs, Lead Times & Specialties

Step 1: Define Your Requirements and Selection Criteria

Before diving into manufacturer evaluations, it’s essential to establish clear requirements. Defining your needs upfront ensures a focused and efficient selection process. Think about your bag type, budget, and desired level of customization.

Identify Your Bag Type and Intended Use

Not all manufacturers are equipped to produce every type of bag. For example, a company specializing in promotional tote bags might lack the expertise to create a waterproof duffel with reinforced stress points. It’s better to align your bag type with a manufacturer’s core strengths rather than opting for a generalist.

Consider the specific features your bag requires. Does it need to be waterproof, impact-resistant, or thermally insulated? For instance, cooler bags demand heat-sealed, leak-proof linings and PE foam insulation, while tool bags require heavy-duty reinforcements and bar-tack stitching at stress points. Sports bags, like pickleball carriers, benefit from vented compartments for shoes or dirty clothes.

Material selection is equally important. Leather is ideal for luxury and durability, nylon or polyester works well for rugged outdoor use, and TPU or PVC ensures watertight construction. Labor costs also vary based on complexity – fabric bags typically have labor costs of 25%–40%, while leather or technically advanced designs can reach 40%–60%.

Determine the quality tier you’re aiming for. Manufacturers often focus on specific categories: high-end/luxury, medium/fast fashion, or promotional/giveaway. For instance, a supplier producing giveaway bags for brands like Nivea operates under different standards than one crafting retail-grade products. Mixing these tiers often leads to unmet expectations. Some markets, like Japan, demand exceptionally high standards for flawless stitching and symmetry.

Once you’ve outlined your bag’s specifications, it’s time to set a realistic budget and determine your order volume.

Determine Your Budget and Order Volume

A realistic budget goes beyond the unit price. Factor in costs for raw materials (often the largest expense), labor, factory overheads, and sampling or prototype adjustments. Sample fees typically range from $20 to $100 per unit, though many manufacturers refund these costs when you place a bulk order.

Align Minimum Order Quantities (MOQs) with your sales projections to avoid tying up capital in excess inventory. In Asia, typical MOQs for custom bag production range from 300 to 500 units per design, though some manufacturers support emerging brands with low-volume runs starting at 100 pieces. For mid-range custom tote bags, expect costs between $6.50 and $9.20 per unit (FOB), with higher complexity driving up prices.

Understand the difference between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) projects. OEM projects require higher budgets and MOQs due to custom tooling and material sourcing, while ODM allows for lower MOQs by using existing factory designs. For new brands, ODM is a practical way to test the market with less financial risk before committing to custom OEM molds.

"MOQs should align with your sales projections to avoid overstocking." – Hermin Fashion

If you’re specifying high-performance materials like Cordura or branded hardware such as YKK zippers, expect higher unit costs. However, these choices ensure durability and reliability. Bulk orders often reduce per-unit costs, thanks to large-scale material procurement by the factory.

Finally, detail your customization and branding needs to finalize your technical specifications.

Outline Your Customization and Branding Requirements

Before approaching manufacturers, prepare a detailed technical specification document. Include exact dimensions, net weight, load-bearing capacity, fabric type and weight (e.g., 420 gsm PU leather or 210 gsm nylon), lining materials, and foam padding density.

Specify hardware preferences, such as zipper brands and sizes (e.g., YKK #9 or SBS), buckles, and sliders. Clearly outline your branding method – whether embroidery, silk-screen printing, heat transfer, debossing on leather, or woven labels – and provide exact placement details and Pantone colors. Don’t forget to detail the internal layout, including compartments, laptop sleeves, mesh pockets, RFID-blocking security pockets, and reinforcement at stress points. Ensure compliance with labeling and safety standards like REACH, CPSIA, or CA Prop 65, as well as "Made in [Country]" tags.

Create a tech pack – a comprehensive document that includes 2D/3D CAD drawings, a Bill of Materials (BoM), and construction sequences. This reduces project risks and ensures clarity. Clarify MOQs not just by design but also by material and color, as these often depend on subcontractors. Always request a production sample to assess touch, color accuracy, and durability before committing to full-scale production.

"The only way to ensure that your bag is made according to specification, is to hire a quality inspector to check up on the goods prior to shipment." – Fredrik Gronkvist, Co-founder, Asiaimportal

Step 2: Research Manufacturers by Geographic Region

Once you’ve outlined your requirements, it’s time to consider how regional factors can refine your choice. Geography plays a big role in shaping costs, production timelines, and specialized manufacturing capabilities. Different regions bring unique strengths, often built on decades of expertise and infrastructure.

Review Regional Manufacturing Capabilities

China leads the global bag market, producing an impressive 70% of the world’s bags and luggage. The country offers a robust supply chain, covering everything from PU leather and recycled fabrics to hardware and packaging. Key regions like Guangdong specialize in high-volume exports, Zhejiang focuses on premium luggage, and Fujian is known for technical products.

Vietnam has gained popularity as a strong alternative to China, especially for technical backpacks and outdoor gear. While its costs are generally 10–20% higher than China, trade agreements like USMCA often help offset these differences. India, on the other hand, is celebrated for its leather goods and artisanal craftsmanship, frequently using natural materials like jute, hemp, and organic cotton. Meanwhile, Turkey stands out for its high-quality European manufacturing, catering to luxury luggage and premium travel accessories for brands targeting European markets.

"China remains the world’s dominant force in bag manufacturing, built on decades of infrastructure development and manufacturing expertise."

– James Kennemer, Founder, Cosmo Sourcing

For North American buyers, Mexico offers a compelling option with expertise in synthetic and leather bag production. Lead times range from just 20 to 45 days – much shorter than the 30 to 75 days typical of Asian suppliers. Thanks to the USMCA trade agreement, Mexico-to-US shipments benefit from reduced duties, similar to the advantages Turkey enjoys under the EU Customs Union. Bangladesh also stands out with its highly competitive pricing – 15–25% lower than Vietnam – making it an attractive choice for high-volume promotional bags.

Next, consider how labor costs and production timelines differ across these regions.

Compare Labor Costs and Production Speed

Labor costs vary widely by region, directly influencing your unit price. China offers low-to-mid labor costs with efficient production for complex orders, typically delivering within 30–60 days. Vietnam’s costs are slightly higher but deliver fast turnarounds for technical products, usually within 35–60 days. Bangladesh provides the lowest labor costs, although lead times can stretch to 40–75 days.

For those seeking faster delivery, nearshoring options like Mexico can be a game-changer. Mexican manufacturers deliver in as little as 2–4 weeks for North American buyers, compared to the 6–8 weeks often required by Asian suppliers. Turkish manufacturers also provide quicker production cycles, typically ranging from 30–50 days for European markets. When planning, don’t forget to factor in potential shipping delays – sea freight from China to the UK, for example, can add 15–30 extra days to your timeline.

Many companies are adopting a "China Plus One" strategy, keeping Chinese suppliers for their scale and efficiency while diversifying with alternatives in Vietnam, India, or Mexico. This balanced approach helps ensure supply chain resilience, especially as the global bags and luggage market is expected to reach $85 billion by 2030.

Once you’ve analyzed costs and timelines, the next step is to evaluate manufacturers’ export and shipping expertise.

Verify International Shipping and Export Experience

Partnering with manufacturers experienced in international shipping and export processes is crucial. Look for factories with "Verified Supplier" status or those that have undergone third-party audits by organizations like SGS or Intertek. Key certifications to check for include ISO 9001 for quality management, BSCI or SA8000 for ethical labor practices, and REACH for chemical safety compliance in EU markets.

Ensure the manufacturer understands your target market’s import regulations, including labeling and compliance standards, as this can simplify your import process. Ask about their shipping methods, relationships with freight forwarders, and documentation procedures. Manufacturers with solid export operations can streamline customs clearance and provide precise landed cost estimates.

Trade agreements can also make a big difference in costs. For example, Mexican manufacturers can use USMCA benefits to reduce or eliminate duties on US-bound shipments, while Turkish suppliers enjoy preferential access to European markets. When comparing quotes, always request FOB (Free On Board) pricing and separately calculate shipping, insurance, and import duties to get a clear picture of your total cost.

Step 3: Evaluate Manufacturing Capabilities

Now that you’ve outlined your criteria and researched potential regions, it’s time to dive into the manufacturers’ technical capabilities and quality practices. This step ensures they can not only meet your current needs but also support your growth as demand increases.

Check Production Capacity and Growth Potential

Start by assessing the factory’s infrastructure – things like production lines, square footage, and workforce size. For example, JUNYUAN BAGS operates six production lines and can produce 200,000 to 250,000 pieces monthly. This kind of scale is crucial if you’re planning to expand beyond small initial orders.

Look for manufacturers with in-house systems that handle everything from design and pattern making to cutting, sewing, and quality control. When all processes are under one roof, you can avoid delays caused by outsourcing and ensure greater consistency. Advanced tools, such as CNC automated cutting machines and CAD pattern systems, can also boost precision and shorten development timelines.

Ask for specific data on on-time delivery rates. For example, Baoding Huicheng Luggage Manufacturing Co., Ltd. boasts a 99.3% on-time delivery rate, while Baoding Xiji Trading Co., Ltd. has a 17% client reorder rate, which is well above the industry average. These figures can give you a sense of how well the manufacturer handles large orders and seasonal spikes.

Also, check if they offer flexible minimum order quantities (MOQs) for test runs. Some factories allow orders as small as 50–100 units while still having the infrastructure to scale up to high-volume production as your brand grows.

Once you’ve reviewed production capacity, shift your focus to the quality of materials and processes.

Examine Material Selection and Quality Controls

The range of materials a manufacturer can source and work with is another key factor. Nylon is a durable choice for rugged use, thanks to its waterproof properties, but eco-conscious brands should inquire about sustainable materials like RPET (recycled polyester) and Flyknit fabrics.

Make sure the factory holds relevant certifications, such as ISO 9001, BSCI, or REACH/RoHS. For specialized products like sports bags, check for compliance with safety standards like NOCSAE for protective equipment. Additionally, use B2B platforms to confirm their "Verified Supplier" status, which indicates third-party verification of their operations.

Ask about their quality control systems. Leading manufacturers often use Root Cause Analysis (RCA) to pinpoint defects caused by suppliers, machinery, or human error. They then implement Corrective and Preventive Actions (CAPA) to minimize recalls and reduce waste.

"We use RCA to find supplier, machine, and human causes of defects, then apply CAPA and supplier fixes to reduce recalls and waste." – JUNYUAN BAGS

Always request physical samples before committing to large-scale production. This allows you to personally evaluate the quality of materials, craftsmanship, and overall finish. While prototyping typically takes 7–10 days, some manufacturers can provide 3D Tech Packs within 48 hours, giving you a digital preview of your design before production begins.

Once you’re confident in material quality and control processes, assess their customization and design capabilities.

Review Customization Services and Design Flexibility

Determine whether the manufacturer provides OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services. OEM services allow you to bring your unique designs to life, though they often require longer lead times. ODM services, on the other hand, provide pre-designed products that can be customized for quicker market entry.

Check if the manufacturer supports in-house design services, including Tech Packs and 3D design capabilities. They should also offer various logo application methods like embroidery, screen printing, or heat transfers. If your product requires specialized features – such as waterproof construction, ergonomic load distribution, or tactical pockets – partner with a manufacturer experienced in those areas rather than a generalist.

Protect your intellectual property by ensuring the manufacturer signs a Non-Disclosure Agreement (NDA) before you share proprietary designs or sensitive information. Be prepared to go through multiple prototype iterations to refine details like materials, stitching, and functionality before finalizing your design.

Regional expertise can also play a role here. China, for instance, produces about 70% of the world’s bags and offers the broadest range of customization options. Vietnam excels in technical backpacks, while Indonesia is known for artisanal, eco-friendly handcrafted bags. Align your customization needs with the strengths of the region to achieve the best results.

Once you’ve reviewed customization and design options, it’s time to compare costs and production timelines to make your final selection.

sbb-itb-1e6451b

Step 4: Compare Pricing, Production Times, and Customization

Once you’ve assessed manufacturing capabilities, it’s time to dive into the numbers. Comparing costs, lead times, and customization options will help you pinpoint the manufacturer that best aligns with your needs.

Build a Comparison Table for Key Metrics

Start by creating a standardized pricing spreadsheet. Use FOB (Free On Board) pricing for 1,000 units as your baseline to ensure consistent comparisons. For example, when evaluating custom cotton canvas tote bags, you might find quotes ranging from $6.50 per unit from Changsha Meicaian E-Commerce to $9.20 per unit from Baoding Huicheng. However, a lower price might come with trade-offs like slower response times or less reliability. Changsha Meicaian, for instance, may take up to 6 hours to respond, while Dongguan Longsheng – priced at $8.50 per unit – typically replies in under an hour and boasts a 98.7% on-time delivery rate.

Your spreadsheet should include columns for minimum order quantities (MOQs), response times, and delivery rates. For example, Baoding Xiji Trading has a standout 17% client reorder rate, which exceeds the industry average and suggests consistent quality. Sample costs generally range from $20 to $100 and are often refundable with a full production order. Be sure to clarify Incoterms (FOB, EXW, or DDP) to fully understand your total landed costs, including shipping and duties.

Production timelines are another critical factor. Compare options like 48-hour 3D Tech Packs versus 7–10 day prototypes. Simpler products, such as tote bags, might take 7–21 days to produce, while more complex items like multi-compartment backpacks could require 35–45 days. If you’re working with tight deadlines, consider manufacturers that offer partial air freight shipments to keep inventory flowing while the bulk order arrives by sea.

Finally, go beyond just the initial price to evaluate long-term value.

Consider Long-Term Value Over Initial Price

As you’ve seen in earlier assessments, focusing solely on the lowest unit price can be misleading. Long-term value often depends on factors like reliability, flexibility, and overall support. For instance, a manufacturer charging $15–$30 per unit with a 500-piece MOQ and a 25–30 day lead time – such as JUNYUAN BAGS – might be a better fit for startups than a supplier offering $8–$15 per unit but requiring 2,000 pieces and 45–60 days. The lower MOQ and faster turnaround allow you to test your market without overcommitting capital to excess inventory.

Reliability metrics are key indicators of long-term value. Take Baoding Huicheng, for example, which has a 99.3% on-time delivery rate. This reliability can justify its higher $9.20 per unit price compared to competitors with less consistent records. As noted in the Alibaba Strategic Guide:

"Repeat business is one of the reliable indicators of consistent performance."

Weighing potential delays or defects against initial savings is crucial. Manufacturers that actively employ Root Cause Analysis (RCA) and Corrective and Preventive Actions (CAPA) to reduce recalls may charge more upfront, but they can save you significant costs in returns and protect your brand’s reputation over time. Once you’ve identified a reliable partner, the investment in building a strong relationship will pay off. This step ties back to your earlier evaluations of production capacity and quality, creating a comprehensive approach to selecting the right manufacturer.

Step 5: Request Samples and Verify Compliance

After crunching the numbers and comparing manufacturers, it’s time to test the waters – literally. This step is all about confirming reliability through hands-on sample testing and verifying compliance with essential standards. Physical samples can reveal what spreadsheets and specs cannot.

Order and Evaluate Product Samples

Start by requesting a 3D Tech Pack to catch any design flaws before full production kicks off. Once the physical sample arrives, put it through its paces. Here’s how:

- Check stitching strength: Firmly pull at the seams to expose any weak spots.

- Test zippers and buttons: Cycle them at least 20 times to ensure durability.

- Assess material quality: Rub a wet white cloth across the fabric to check for color fastness and apply water to see if it’s truly waterproof.

- Perform load and durability tests: Tailor these to your bag’s design to ensure it can handle real-world use.

If the sample meets your quality standards, you’re ready to move on to compliance and production processes.

Confirm Certifications and Production Standards

Even if the sample looks great, it’s critical to ensure the manufacturer meets required certifications. Ask for copies of their certifications, such as ISO 9001:2015, BSCI, CPSIA (for U.S. products), REACH, CE, or GRS (for sustainability). Don’t just take their word for it – verify expiration dates and keep track of them using tools like Trello or Notion.

For specialty items like food-grade gift bags, certifications such as FSSC 22000 are essential. Keep in mind, though, that achieving this certification can cost up to $15,000 depending on the factory’s readiness.

Set Up Clear Communication Processes

The sampling phase is also a test of the manufacturer’s communication skills. During the typical 7–10 day prototyping period, ensure you have direct access to senior team members who can address issues promptly. Establish a clear approval workflow to avoid misunderstandings. Mass production should only begin once you’ve explicitly approved the physical sample. For example, Junyuan Bags outlines their process as follows:

"Once the sample is complete, we will ship it to you for your approval, and production will begin immediately after your approval on sample." – Junyuan Bags

To streamline this process, document every detail – Incoterms (such as FOB, EXW, or DDP), material preferences, logo specifications, and any other critical requirements. A manufacturer who stays responsive, offers helpful technical advice, and maintains clear communication throughout the sampling phase is likely to become a dependable long-term partner. This step ties together all the technical and logistical groundwork you’ve laid so far.

Conclusion

Choosing a bag manufacturer isn’t just about finding the lowest price – it’s about finding a partner who can consistently deliver quality, meet your customization needs, and grow alongside your business. Start by clearly defining your requirements, such as the type of bag, your budget, and minimum order quantities (MOQs). Research regional strengths to match your needs – for example, China excels in intricate designs, Vietnam specializes in technical gear, and India is known for leather craftsmanship.

It’s also crucial to look beyond the unit price and consider the total cost of ownership. This includes shipping fees, import duties, and quality control expenses. Always request samples to verify the materials and construction quality. As mentioned earlier, certifications and compliance are essential to ensure consistent standards.

"Choosing the right bag manufacturer is key to a successful order." – Rocket Bags

Building a long-term relationship with your manufacturer can deliver benefits well beyond your first order. Trusted manufacturers who understand your brand often achieve reorder rates of 17% or higher. To strengthen supply chain resilience, many brands now adopt a "China Plus One" strategy – retaining a primary supplier in China while developing secondary partnerships in Vietnam, India, or Mexico.

With the global bags and luggage market projected to hit $85 billion by 2030, sustainability and digital innovation are transforming how manufacturers work. Look for factories that use eco-certified materials and advanced tools like 3D Tech Packs. Treat your manufacturer as a long-term partner and invest the time upfront to ensure enduring quality.

FAQs

What should I look for when choosing a bag manufacturer?

When choosing a bag manufacturer, there are a few key factors to keep in mind to ensure they meet your needs both now and in the future. Start by evaluating their production capacity. Can they handle your current order size? More importantly, are they equipped to scale up as your business grows? Look for clear lead times and a track record of dependable delivery schedules.

Pay close attention to quality certifications. Certifications like ISO 9001 or compliance with U.S. standards such as CPSIA are good indicators of consistent craftsmanship and adherence to legal requirements. Don’t forget to review their material options. A trustworthy manufacturer should be transparent about their sourcing and offer a variety of materials, such as nylon, polyester, or even recycled fabrics. Bonus points if they show a commitment to environmentally friendly practices.

Customization is another area to evaluate. A manufacturer should provide flexibility when it comes to logos, sizes, colors, and patterns – and they should do so without requiring sky-high minimum order quantities (MOQs). At the same time, take a close look at their pricing structure. Make sure all costs, including shipping and tariffs, are clearly outlined in U.S. dollars to avoid surprises down the line.

Finally, don’t overlook the importance of communication and support. A responsive team that can manage design adjustments, oversee quality control, and provide after-sales service is crucial for a smooth experience. For instance, JUNYUAN BAGS stands out by offering certified production, customizable options, and full-service support tailored specifically for U.S. customers.

How do regional differences affect the cost and quality of bag manufacturing?

Regional dynamics play a big role in shaping both the cost and quality of bag production. Take China, for instance – it accounts for roughly 70% of global bag manufacturing. This dominance is fueled by large-scale operations, advanced production technologies, and streamlined supply chains. However, increasing labor costs and tariffs have pushed many brands to consider alternatives like Vietnam, Bangladesh, or Mexico. These countries often offer lower labor costs and the advantage of sourcing materials locally, which can cut expenses. That said, these savings might come with the need for stricter quality oversight.

On the other hand, manufacturers based in the United States or Europe typically have higher labor costs. But they offer benefits like faster delivery for domestic orders, stricter quality control, and easier adherence to local safety and environmental regulations. By partnering with a supplier like JUNYUAN BAGS, you can tap into the precision of Chinese manufacturing for intricate designs while leveraging cost-effective production in other regions for simpler styles. This approach ensures a smart balance between quality, affordability, and meeting customer expectations.

What certifications ensure a bag manufacturer meets quality and ethical standards?

When choosing a bag manufacturer, it’s important to look for certifications that reflect their commitment to quality, safety, and ethical practices. Here are some key certifications to consider:

- ISO 9001: This certification focuses on quality management, ensuring the manufacturer meets consistent quality standards.

- BSCI or SA8000: These indicate compliance with social responsibility and fair labor practices.

- SEDEX: Highlights ethical supply chain management and responsible sourcing.

For manufacturers prioritizing environmentally friendly production, certifications like GRS (Global Recycled Standard) confirm the use of recycled materials, while ASTM D6400 or EN 13432 verify the use of biodegradable materials. Additionally, OEKO-TEX® ensures textiles are safe and free from harmful substances, and FSSC 22000 is a must if the bags are intended for food-related use.

These certifications not only validate the manufacturer’s adherence to high standards but also demonstrate their commitment to sustainable and ethical practices.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD