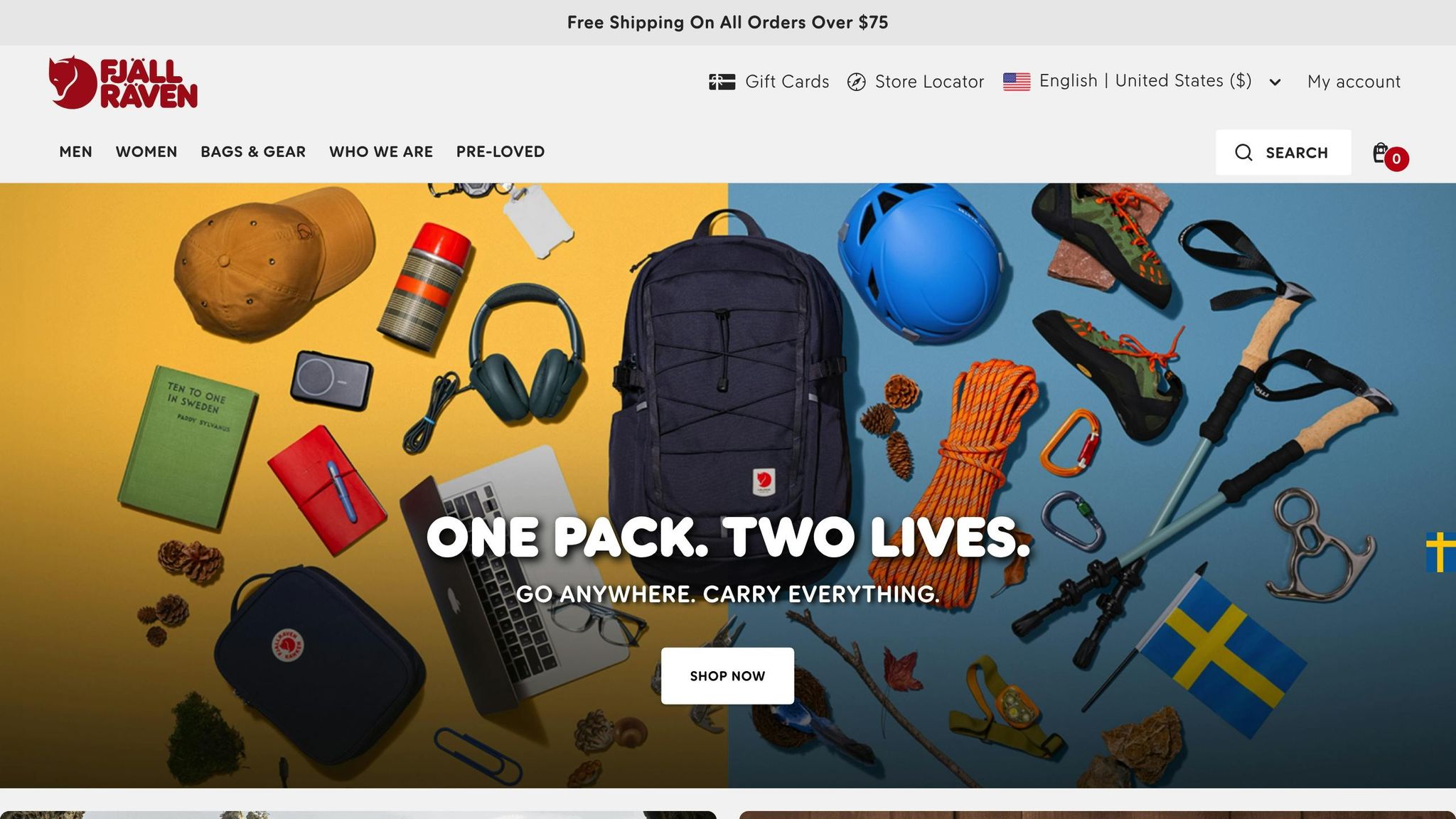

Fjällräven is reshaping custom sports bag production by partnering with Chinese OEM manufacturers who specialize in eco-materials and efficient production methods. Here’s what you need to know:

- Focus on Sustainability: Fjällräven uses recycled polyester, organic cotton, bio-based polyamides, and hemp fabrics to reduce reliance on harmful resources.

- Advanced Manufacturing: Chinese OEMs integrate waterless dyeing, closed-loop recycling, and energy-saving technologies to lower production impact.

- Certifications Matter: Products meet U.S. standards, including BSCI, ISO9001, and RoHS compliance.

- Digital Tools: Platforms like Flexport enhance supply chain transparency and efficiency, aligning with sustainability goals.

This approach not only meets rising U.S. consumer demand for eco-conscious products but also ensures high-quality, durable, and functional bags tailored to specific needs.

Chinese OEM Manufacturing: Custom Sports Bag Production Hub

What Chinese OEM Manufacturers Can Do

Chinese OEM manufacturers have stepped up their game in recent years, offering advanced capabilities like eco-friendly material integration, rapid prototyping, and high-level customization for U.S. sports bags. No longer limited to basic assembly, these manufacturers now handle complex custom designs and use sustainable materials such as recycled polyester, organic cotton, and bio-based alternatives.

This shift means they can produce sports bags with unique designs and specialized features tailored to meet specific user needs. Many are also exploring innovative materials, replacing traditional synthetics with eco-friendly options to meet the growing demand for sustainable products in the U.S. market – all while maintaining the performance standards consumers expect. These advancements come with a strong focus on quality control to ensure every product meets rigorous standards.

Quality Standards and Required Certifications

To sell in the U.S., manufacturers must adhere to strict certifications. These include:

- BSCI: Ensures ethical labor practices in production.

- ISO9001: Confirms robust quality management systems.

- RoHS Compliance: Required for sports bags with electronic components, ensuring safety and environmental responsibility.

OEM vs. ODM: Custom Manufacturing Differences

When it comes to custom sports bag production, the choice between OEM and ODM services depends on your business needs:

- OEM (Original Equipment Manufacturer): These services strictly follow your design and branding specifications, offering full control over the product’s look and functionality.

- ODM (Original Design Manufacturer): With ODM, manufacturers provide pre-designed templates that can be customized, speeding up production and cutting development costs.

For businesses with limited internal design resources, ODM can be a quicker and more cost-effective option. However, those seeking full creative control may prefer the flexibility of OEM partnerships. The decision ultimately hinges on your design capabilities and strategic goals.

Eco-Material Technologies in Fjällräven‘s Manufacturing

New Materials: Recycled Polyester, Organic Cotton, and More

Fjällräven’s Chinese manufacturing partners have embraced a range of sustainable materials that go far beyond traditional options. A standout example is recycled polyester, made from post-consumer plastic bottles and textile waste. This material not only delivers durability and weather resistance but also helps reduce the strain on natural resources.

Another key component of their strategy is organic cotton, which is cultivated without relying on heavy pesticides or harmful chemicals. This approach not only protects soil health and improves worker safety but also provides natural breathability and comfort. Fjällräven incorporates organic cotton into linings and interior components of their sports bags, ensuring both functionality and sustainability.

The company has also introduced bio-based polyamides, derived from castor oil plants. These materials offer the strength and flexibility needed for high-performance sports bags while cutting down on the use of petroleum-based resources. Additionally, hemp-based fabrics – known for their natural antimicrobial properties and long-lasting durability – have been integrated into their designs. Hemp requires less water to grow and even improves soil quality, making it an excellent choice for environmentally conscious production.

These material choices lay the groundwork for equally innovative and sustainable production processes.

Eco-Friendly Production Methods

Fjällräven’s partners have adopted cutting-edge production techniques designed to minimize environmental impact. For instance, they use waterless dyeing methods with supercritical CO₂, which significantly reduces water consumption. Solar panels, LED lighting, and closed-loop recycling systems are also employed to conserve energy and raw materials. These recycling systems allow fabric scraps and production waste to be repurposed into new materials, reducing the need for virgin resources while maintaining product quality.

In addition, the company has replaced traditional finishing processes with low-impact chemical treatments. These treatments ensure water resistance and durability without relying on harmful substances, creating a safer production environment and cleaner end products for consumers.

How These Materials Match Fjällräven’s Environmental Goals

Fjällräven’s choice of materials and production methods aligns seamlessly with its broader environmental mission. By prioritizing durable, sustainable materials, the company stays true to its philosophy of creating long-lasting products that minimize waste.

The emphasis on recycled content and recyclability supports a circular economy, where used sports bags can be transformed into raw materials for future products. This approach reduces waste and encourages a more sustainable lifecycle for their goods.

Moreover, Fjällräven maintains transparent and traceable supply chains, allowing the company to back up its environmental claims with verifiable data. This level of openness resonates with eco-conscious customers, who value knowing the real impact of their purchases.

For U.S. businesses looking to adopt similar practices, Fjällräven’s approach shows that sustainability doesn’t have to come at the expense of performance or efficiency. It’s a clear example of how environmental responsibility can work hand-in-hand with innovative manufacturing.

Digital Tools in OEM Partnerships

Digital Platforms in Supply Chain Management

Fjällräven has teamed up with Flexport, a digital logistics platform, to bring greater transparency and accountability to its manufacturing processes in China. By using Flexport’s tools, Fjällräven gains better control over its supply chain while advancing its sustainability goals through data-driven strategies. The platform includes features like an advanced CO₂ calculator, detailed analytics, AI-powered route and mode optimization, and container planning to improve efficiency. A standout feature is Flexport’s marine biofuel certificates, offered through a book-and-claim system, which allow companies to invest in cleaner shipping fuels, helping reduce overall emissions. Additionally, Fenix Outdoor‘s Occtoo Experience Data Platform is extending the use of digital tools into supply chain management, enhancing product development efforts. These technologies not only improve supply chain oversight but also create opportunities for more tailored product offerings.

Effects on Product Development and Customization

Flexport’s insetting options enable Fjällräven to directly support emission reduction projects, reinforcing its commitment to sustainable manufacturing.

Benefits for US Custom Sports Bag Industry

Fjällräven’s focus on eco-conscious production, supported by digital platforms, brings clear advantages for the US custom sports bag market. Its digital transformation equips US businesses with better transparency and the ability to make smarter, data-informed decisions. For manufacturers of custom sports bags, integrating sustainability metrics into digital platforms offers a competitive advantage, especially as consumers increasingly demand insight into the environmental impact of the products they buy. This shift reflects a broader industry trend toward greener, data-driven production practices. Moreover, digital platforms simplify the comparison of logistics options – highlighting costs, delivery times, and environmental impacts – making it easier for US companies to choose alternatives to air freight that align with their sustainability goals.

sbb-itb-1e6451b

Takeaways for US Businesses: Using Green OEM Solutions

JUNYUAN BAGS‘ Custom Manufacturing Services

JUNYUAN BAGS specializes in OEM and ODM manufacturing, focusing on eco-friendly production methods. They offer custom design services for a variety of bags, including sports, travel, and equipment bags. This allows US businesses to integrate sustainable materials into their product lines while maintaining a high level of customization.

Their free design consultations cover everything from material selection to logos, dimensions, and patterns. JUNYUAN BAGS holds essential certifications like BSCI, CE, RoHS, and ISO9001, ensuring compliance with US environmental and quality standards. Additionally, their sample creation process gives businesses the chance to test eco-friendly materials before committing to full-scale production. This minimizes waste and supports sustainability goals.

These tailored services are crafted to address the specific needs of the US market.

Meeting US-Specific Requirements

For US businesses, it’s crucial to recognize the differences in regulations and market expectations compared to Europe. Factors like production costs, detailed product specifications, and customized shipping requirements must align with US standards.

Key details such as product dimensions, weight, and material thickness should be clearly defined in both imperial and metric units. When opting for recycled or eco-friendly materials, businesses must ensure these materials meet all applicable US safety and environmental regulations.

Careful selection of eco-materials can enhance the appeal and functionality of your custom bag offerings.

Eco-Materials Comparison for Custom Bags

When choosing eco-materials, it’s important to weigh their individual strengths. Recycled polyester stands out for its durability and affordability, making it a go-to option for gym and travel bags. Organic cotton provides a natural, low-impact alternative, perfect for casual or lifestyle bags. Hemp blends are prized for their strength and environmental benefits, ideal for heavy-duty uses. Meanwhile, recycled nylon offers superior abrasion resistance, making it a smart choice for technical sports and outdoor gear.

Why is Fjällräven so expensive?

Conclusion: Green Manufacturing as the Future of Custom Bags

Fjällräven’s collaboration with Chinese OEM manufacturers demonstrates that eco-friendly materials can successfully combine environmental responsibility with top-tier custom bag production. These partnerships highlight how sustainable practices are reshaping the custom bag industry.

This shift addresses the increasing environmental awareness among US consumers. For businesses entering the custom bag market, adopting green manufacturing isn’t just an option – it’s becoming the expectation. Companies that prioritize eco-materials and sustainable production methods today will be better equipped to meet the growing demand for environmentally conscious products.

Digital platforms make it easier for US businesses to connect directly with certified manufacturers who uphold high environmental standards without compromising on quality.

JUNYUAN BAGS serves as a prime example of this transformation, incorporating eco-friendly materials, advanced customization options, and certifications like BSCI, CE, RoHS, and ISO9001 to meet stringent US requirements.

The future clearly favors manufacturers who can strike the right balance between sustainability, customization, and quality. As more brands follow Fjällräven’s example by partnering with environmentally conscious OEM manufacturers, the custom bag industry will continue moving toward greener practices. For US businesses ready to embrace this change, the tools and expertise are already available. The real question now is not whether to adopt green manufacturing, but how quickly it can become a core part of their strategy.

FAQs

How do Fjällräven’s eco-friendly materials, like recycled polyester and organic cotton, support sustainability in custom sports bag manufacturing?

Fjällräven takes sustainability seriously by incorporating recycled polyester and organic cotton into their custom sports bags. Recycled polyester helps cut down on the use of new raw materials, conserves natural resources, and requires less energy to produce. Meanwhile, organic cotton is grown with reduced water usage and avoids harmful chemicals like pesticides and synthetic fertilizers, which helps preserve ecosystems and supports biodiversity.

By choosing these materials, Fjällräven actively supports a circular economy and promotes environmentally responsible production practices. This approach not only reflects the company’s dedication to sustainability but also serves as a model for how eco-friendly innovations can shape the future of the sports bag industry.

What is the difference between OEM and ODM services, and how do they affect the customization of sports bags?

OEM (Original Equipment Manufacturer) services let clients take the reins when it comes to product design. With this option, businesses can submit their own detailed designs and specifications, ensuring they maintain full control over the product’s design and intellectual property. This results in highly tailored sports bags that align perfectly with their vision. However, this level of customization often comes with a trade-off: higher costs and longer production timelines.

ODM (Original Design Manufacturer) services, by contrast, offer a more streamlined approach. Manufacturers provide pre-designed products that allow for limited customization. While this option is quicker and more budget-friendly, it doesn’t offer the same level of design flexibility as OEM.

Choosing between OEM and ODM shapes the customization journey for sports bags. It’s all about balancing design control, production speed, and overall cost to meet your specific needs.

How do digital platforms like Flexport help Fjällräven improve supply chain transparency and meet sustainability goals?

Digital platforms such as Flexport are transforming supply chain management by providing real-time tracking, in-depth monitoring, and precise data on environmental impact. For Fjällräven, this means pinpointing opportunities to improve efficiency while ensuring their manufacturing processes align with eco-conscious goals.

By leveraging tools like big data, analytics, and blockchain, these platforms help optimize logistics, cut emissions, and validate sustainability initiatives. This not only streamlines operations but also reinforces Fjällräven’s dedication to environmentally responsible manufacturing and ethical sourcing.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD