Designing team sports bags involves balancing durability, functionality, and personalization. These bags serve as essential tools for athletes, providing organized storage for gear while promoting team identity. Here’s what you need to know:

- Materials: Durable options like 900D polyester or nylon resist wear and tear. Ventilated compartments and waterproof bases protect gear from odors and moisture.

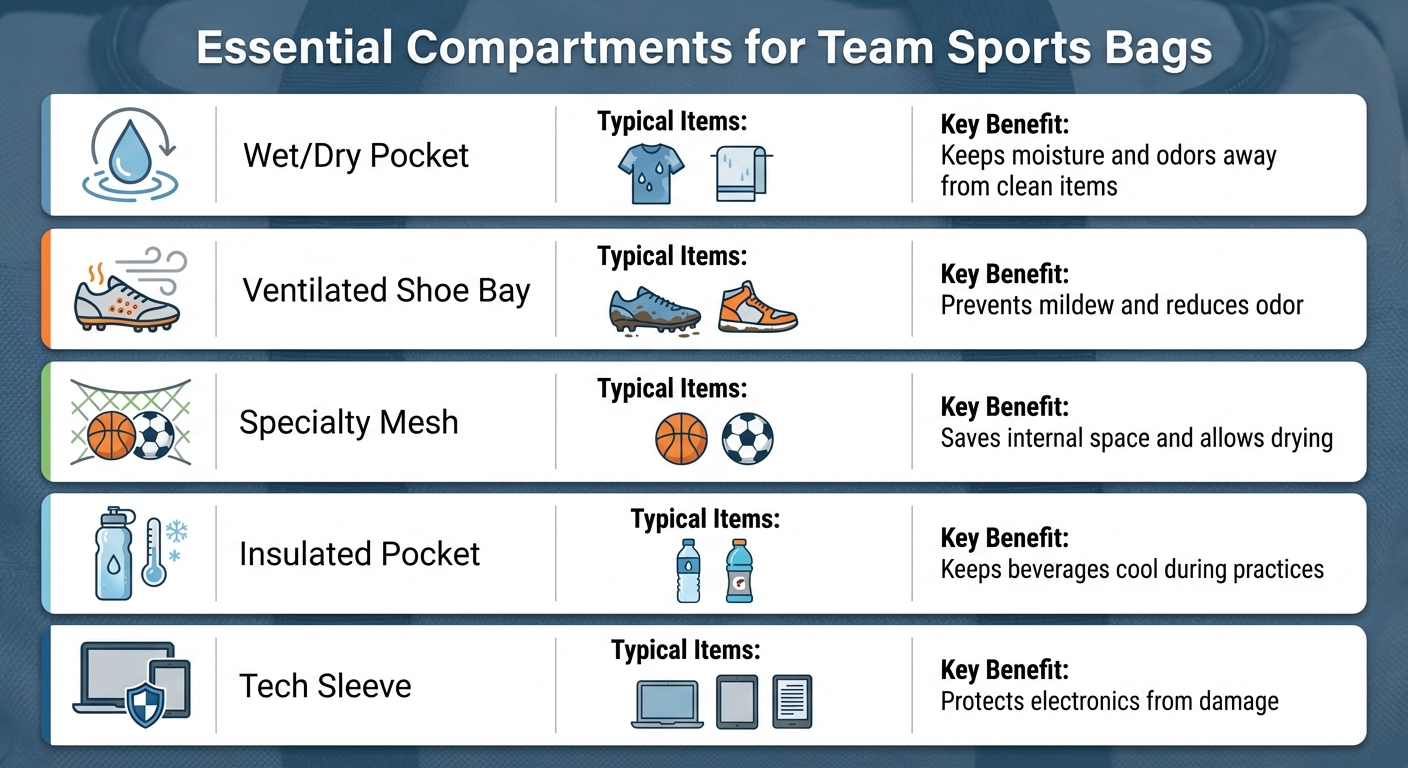

- Compartments: Include wet/dry pockets, ventilated shoe bays, and tech sleeves. External mesh storage for balls and insulated sections for drinks enhance usability.

- Portability: Padded straps, sternum supports, and hybrid designs improve comfort. Wheels on larger bags simplify transport for heavy gear.

- Customization: Add logos, team colors, names, and numbers using embroidery, screen printing, or sublimation for a polished look.

- Prototyping: Test designs for quality and functionality before bulk production to ensure they meet athletes’ needs.

High-quality team bags not only protect equipment but also strengthen team spirit. Prices range from $33 to $98.99, with production timelines of 30-45 days for orders starting at 500 units.

Embroidering A Personalized Gym Bag

Understanding Team Sports Requirements

Team Sports Bag Compartment Types and Benefits Comparison

Every sport comes with its own set of gear, which directly influences the design of an athlete’s bag. For instance, basketball players need space for a Size 7 regulation ball, court shoes, and accessories like arm sleeves and mouthguards. Soccer players require room for a Size 5 ball, cleats, shin guards, and training jackets. Meanwhile, football players carry helmets, pads, and other heavy-duty protective equipment, requiring bags with reinforced construction. Regardless of the sport, certain essentials are universal: water bottles, cooling towels, ball pumps with needles, personal electronics like headphones and tablets, and medical supplies such as instant cold packs, first aid kits, and extra mouthguards. The sections below dive into equipment needs, portability features, and specialized compartments.

Evaluating Equipment and Gear Needs

The size and weight of gear vary widely between sports. For example, basketball and soccer bags typically need to accommodate a ball, shoes, and a uniform. On the other hand, football players’ bulky helmets and pads call for extra-large duffle bags. Additionally, medical and safety items should have dedicated, easily accessible compartments. Items like instant cold packs, first aid kits, ibuprofen, and extra mouthguards are critical and shouldn’t be buried under piles of clothing.

Beyond just capacity, bag versatility has become increasingly important. Many student-athletes prefer multi-functional designs that can transition seamlessly between the classroom and the court. Gloria, a professional team gear supplier, highlights this trend:

"These multi-purpose backpacks can potentially save you a lot of money as they make additional gym bags unnecessary!"

Modern bags often include protective sleeves for laptops and tablets, making them suitable for both academics and athletics.

Prioritizing Portability and Convenience

The way athletes travel with their gear plays a big role in determining bag style. Backpacks with padded shoulder straps and sternum straps are great for commuters who bike or use public transit, as they distribute weight evenly. Duffle bags, with their larger open design, are ideal for bulkier equipment and fit easily into gym lockers. Hybrid bags offer the flexibility to switch between backpack straps and duffle handles, catering to different needs.

Custom duffle bags typically measure 22" L x 12" W x 13" H, while larger versions for high-volume gear can go up to 28" L x 14" W x 14" H. For air travel, smaller duffles often meet carry-on size requirements. When it comes to heavier gear, like golf equipment, integrated wheels make transportation much easier. As USA Teamwear points out:

"a duffle bag needs to be rugged, spacious, and highly visible… built with durable, heavy-duty materials to withstand constant travel and rough handling"

Features like quick-access exterior pockets keep essentials within easy reach during travel. Water-resistant bottoms protect gear from wet locker room floors or sideline conditions. Additionally, external mesh netting for ball storage helps free up internal space, keeping the bag neat and organized.

Wet/Dry Separation and Specialty Compartments

Keeping sweaty uniforms and muddy cleats separate from clean clothes and electronics is a must. Bags with ventilated compartments for shoes help air circulation, reducing odors and preventing mildew. Dick’s Sporting Goods emphasizes this point:

"The right basketball bag should have plenty of space for whatever you might need on the hardwood. It should be able to fit your gear and clothes, offer space for personal belongings like a phone or wallet and have easy access to all of those items"

Here are some key compartment types and their benefits:

| Compartment Type | Typical Items Stored | Key Benefit |

|---|---|---|

| Wet/Dry Pocket | Sweaty uniforms, wet towels | Keeps moisture and odors away from clean items |

| Ventilated Shoe Bay | Cleats, basketball shoes | Prevents mildew and reduces odor |

| Specialty Mesh | Basketballs, soccer balls | Saves internal space and allows drying |

| Insulated Pocket | Water bottles, sports drinks | Keeps beverages cool during practices |

| Tech Sleeve | Laptops, tablets, e-readers | Protects electronics from damage |

Athletes should store court shoes in a separate compartment and only wear them at the venue to keep the soles clean and maintain grip. This habit not only extends the life of the shoes but also enhances on-court performance. Insulated pockets are another practical feature, keeping drinks cool during long practices, while soft-lined tech sleeves shield electronics from impacts and moisture.

Selecting Durable Materials and Construction Techniques

The materials and construction methods you choose can make the difference between a sports bag that lasts a single season and one that holds up for 5 to 10 years. Polyester and nylon are the go-to options for most manufacturers because they balance strength, weight, and cost. For example, polyester in 900D (denier) weights is tough enough to handle daily wear and tear without breaking the bank. On the other hand, nylon is lighter and more water-resistant, making it a smart choice for outdoor or rainy conditions.

Material Comparison: Nylon vs. Polyester

Each material has its advantages, and the best choice depends on the sport and environment. Nylon is a winner in wet conditions, such as water polo, because it naturally repels moisture. Polyester, however, shines when it comes to abrasion resistance, making it ideal for gym floors and locker rooms. For those looking for eco-friendly options, RPET (recycled polyester) offers similar durability while aligning with sustainability goals.

| Material | Strength | Weight | Cost | Best Use Case |

|---|---|---|---|---|

| Nylon | High | Lightweight | Moderate | Water sports, outdoor use |

| Polyester (900D) | High | Moderate | Economical | General sports, gym bags |

| RPET | Moderate/High | Moderate | Moderate | Eco-conscious branding |

The price of a bag often reflects its material. Budget-friendly options usually fall between $12.99 and $28.99, while high-end bags made with advanced materials can range from $60.99 to $96.99.

But selecting the right fabric is just the start – how the bag is constructed plays a major role in its durability.

Reinforced Stitching and Padding

Once you’ve picked the right material, construction quality becomes key. Stress points like handles, shoulder straps, and zipper connections need strong stitching to withstand the daily abuse of being tossed into lockers or dragged across parking lots. Features like padded straps and reinforced compartments not only protect your gear but also make carrying heavy loads more comfortable.

Durable construction also ensures branding lasts. For example, sewn-on twill logos hold up far better through repeated washes than screen-printed designs.

Ventilation and Abrasion Resistance

Ventilation is essential for keeping gear fresh and odor-free. Mesh panels in compartments designed for shoes or sweaty clothes allow airflow, reducing the risk of mildew and bacteria buildup. Some manufacturers go a step further by incorporating anti-microbial linings like FreshPAK™ technology to combat odor-causing bacteria. External mesh pockets for items like balls or shoes can provide even better ventilation than internal compartments.

The base of the bag, which often faces the most abuse from rough or wet surfaces, needs extra protection. Materials like tarpaulin or heavy-duty 900D Oxford fabric are excellent choices for resisting tears and water damage. As Amie Wilkerson, an expert in athletic gear, puts it:

"With proper ventilation sweaty clothes, wet bathing suits, stinky sneakers, and whatever else you carry in your shoe compartment, are able to air out".

These thoughtful design features not only keep your gear in better condition but also significantly extend the life of your sports bag.

Planning Functional Compartments and Features

Designing a sports bag that meets the needs of athletes means organizing the interior to reflect how they actually use their gear. A thoughtful layout ensures that everything is easy to find without having to unpack the entire bag. The secret lies in creating dedicated compartments tailored to the demands of practice, games, and travel.

Multiple Pockets for Gear Organization

Athletes need compartments that cater to their specific gear. For instance, a separate shoe compartment not only keeps things organized but also helps manage odors effectively. Sports like basketball and soccer benefit from specialized ball storage, such as padded or mesh exterior pockets, which keep the ball secure and easy to grab. This kind of organization is especially helpful for youth and amateur teams, making gear management less of a hassle.

Hydration is another priority. Side pockets for water bottles allow athletes to stay refreshed without digging into the main compartment. Some designs go a step further with insulated compartments that maintain the temperature of snacks and drinks, which is perfect for long outdoor events.

Comfortable Straps and Handles

Once the interior is sorted, comfort becomes the next priority. Wide, padded straps help distribute weight evenly across the shoulders, making it easier to carry heavy equipment. Straps with ergonomic padding that molds to the shoulder can prevent slipping, while non-slip backings keep everything securely in place.

Adjustable straps are a must-have since athletes of all ages and sizes need a personalized fit for maximum comfort.

Tech Sleeves and Quick-Access Features

In addition to organizing gear, modern sports bags need to accommodate tech devices and small essentials. Athletes often carry smartphones, tablets, and headphones, so padded tech sleeves protect these items from damage. RFID-secured pockets add an extra layer of security for cards and IDs. Placing these compartments in easily accessible spots – like on the exterior or a front panel – means athletes can grab what they need without disturbing the rest of their gear.

External pockets for keys, transit passes, and phones are another game-changer. They eliminate the need to rummage through the bag, saving time and frustration. For teams that travel, ensuring these quick-access compartments meet airline carry-on guidelines can streamline the airport experience . These thoughtful additions turn a standard bag into a versatile companion for both the court and the road.

sbb-itb-1e6451b

Incorporating Customization for Team Branding

Customization transforms a sports bag from a simple accessory into a powerful emblem of team spirit. Beyond its practical use, a customized bag becomes a badge of identity, uniting teammates and making gear instantly recognizable at games, tournaments, and practices.

Adding Team Logos and Colors

Adding team logos and colors is an essential step in creating a cohesive and professional look. The method used to apply the logo plays a big role in both its appearance and longevity. For a premium, long-lasting finish, embroidery is a top choice. It weaves the logo directly into the fabric, ensuring durability and a high-end look:

"Embroidery creates a premium, durable look that’s perfect for bags. The logo or text becomes part of the bag rather than just printed on top." – Custom Ink

If you’re working with simple, one or two-color designs and need to order in bulk (24+ pieces), screen printing offers an efficient and cost-effective solution. For that polished, professional sports vibe, tackle twill is an excellent option. This technique involves sewing poly/cotton twill fabric onto the bag, giving it a "pro-league" feel.

For vibrant, full-color designs, sublimation printing is the way to go. This method works especially well with polyester bags, ensuring colors stay bright and resistant to fading over time. If your design includes oversized logos, pre-construction printing is a smart choice. This approach applies logos to fabric panels before the bag is assembled, avoiding issues with seams or pockets that could disrupt the design.

Personalizing Names and Numbers

Adding names and numbers to sports bags not only helps with quick identification but also fosters a sense of personal ownership. Sublimation printing embeds ink directly into the bag’s fibers, ensuring that personalization remains durable through heavy use. For high-contact sports, tackle twill offers a robust option by sewing names and numbers directly onto the bag.

For a more budget-friendly solution, Thermo-FILM heat-applied letters are a solid choice, with pre-cut sets starting at around $1.17 per name or number. If you want the look of stitching without the extra labor, SimStitch® provides a no-sew alternative. It uses a heat press to mimic the classic zig-zag stitch, delivering a professional appearance. For bags that might be shared or rotated among team members, laminated tags are a practical option. These durable tags, sealed in 14 mil thick pouches, can last an entire season.

Choosing Patterns and Themes

Incorporating thoughtful patterns and themes elevates the bag’s design while reinforcing the team’s identity. Repeating the team logo across the bag’s surface creates a visually cohesive look, while double-sided designs offer flexibility – one side can showcase a bold team pattern, while the other highlights individual player details. Adding role-specific designations, like a "C" for captains, further emphasizes team structure.

When planning custom patterns, it’s important to position text and logos carefully to avoid seams or metal eyelets that could obscure the design during manufacturing. Coordinating the bag’s design with team uniforms creates a unified and polished appearance, especially for travel and competitions. For a timeless, personal touch, consider a classic three-letter monogram layout, with the last name initial in the center, flanked by the first and middle initials.

JUNYUAN BAGS specializes in offering tailored customization options, incorporating these advanced branding techniques to bring your team’s vision to life.

Prototyping and Iterating Bag Designs

Once you’ve nailed down the details of your design and customization, prototyping is where your ideas start to take shape. This step is critical for ensuring your bag design is practical and functional before committing to full-scale production. It’s your chance to test, tweak, and perfect – saving time, money, and headaches later.

Creating Initial Prototypes

The prototyping process starts with turning your sketches into a tech pack. Think of the tech pack as the blueprint for your bag – it includes detailed measurements, material specifications, hardware placements, and construction methods. From there, designers often create paper models to test patterns. This low-cost step helps identify design flaws early, before moving on to a physical prototype.

Once the paper model checks out, manufacturers use it to develop cutting patterns and produce a physical sample. Typically, this process takes about 7 to 10 days. When discussing prototype fees, confirm that the cost covers both the cutting patterns and the sample itself. Be wary of manufacturers offering prototypes in less than a week at low costs – rushing this step can lead to mistakes or a poorly executed design.

With your prototype in hand, it’s time to put it through its paces.

Testing for Durability and Usability

A prototype isn’t just for show – it needs to perform. Start with load and stress testing: fill the bag with the type of items it’s designed to carry and ensure it holds up under real-world conditions. Check that reinforced stitching and durable fabrics can handle the strain without tearing. Test zippers, straps, and any specialized compartments, like waterproof linings or ventilated pockets, to ensure they work as intended.

Material testing is equally important. Whether you’re using nylon, polyester, or TPU, evaluate its water resistance, abrasion resistance, and color retention. If your design includes sublimated logos, make sure they resist fading, peeling, or cracking. For example, JUNYUAN BAGS once completed a 48-hour prototyping phase followed by rigorous testing for an NCAA basketball team, resulting in a flawless 300-unit order.

Before moving forward, request a sample proof to double-check fabric quality, construction, and color accuracy. Test the bag in real-life scenarios: does it comfortably hold both a laptop and gym gear? Do the attachment loops stay secure during travel? These practical tests often reveal issues that aren’t apparent on paper.

Approval and Bulk Production

Once testing and revisions are complete, it’s time to finalize the design. Collaborate with your manufacturer to refine any last details. If major changes are needed, don’t hesitate to request a second prototype. As one expert explains:

"The prototyping process should be a partnership where the manufacturer uses its deep knowledge and expertise to help you improve and realize your item." – nobrand custom

After final approval, you’re ready for bulk production. This stage typically takes 30 to 45 days, with minimum order quantities starting at 50 units for test batches and scaling to 500 or more for standard runs. Once the prototype is approved, factories can scale production quickly – some can produce 200,000 to 250,000 pieces per month.

JUNYUAN BAGS streamlines the entire process, from idea sharing and material selection to sample creation and mass production. Their approach ensures your team bags meet both functional and aesthetic needs before they hit the field.

Conclusion

A strong design foundation is key to creating team sports bags that combine performance with a cohesive brand identity. The perfect bag strikes a balance between practicality, durability, and customization. Features like organized compartments, water-resistant materials, and team branding not only make the bags functional but also help strengthen team unity.

Comfort and usability are just as crucial. Padded straps and ergonomic designs make carrying heavy gear easier, while mesh panels provide ventilation to keep equipment fresh. These thoughtful details elevate a bag from a simple storage solution to an essential tool for athletes, enhancing both their performance and their sense of team cohesion.

When it comes to manufacturing, expertise matters. JUNYUAN BAGS brings over two decades of experience, producing more than 200,000 pieces monthly and holding certifications like ISO 9001 and BSCI. Their streamlined prototyping process – completed in as little as 72 hours – allows for testing and refining designs before committing to mass production.

Every design decision impacts how athletes carry and protect their gear. Custom team bags typically range from $33 to $98.99, with minimum order quantities starting at 500 units. With lead times of 30 to 45 days, early planning ensures teams have high-quality, personalized gear ready for the season. By focusing on these essential elements, teams can equip themselves with bags that not only meet their practical needs but also inspire team spirit.

FAQs

What are the best materials for making durable team sports bags?

When creating team sports bags, selecting the right material plays a huge role in ensuring both durability and practicality.

- Nylon stands out as the go-to material for heavy-duty sports bags. Known for its strength, tear resistance, and flexibility, it’s an excellent choice for outdoor activities or situations that demand tough, long-lasting gear.

- Polyester is a solid pick for lighter or budget-conscious designs. It’s water-resistant and easy on the wallet, though it doesn’t quite match nylon’s durability.

- PU leather adds a touch of style, making it a great option for bags where appearance matters most. It’s scratch-resistant but less flexible and not as tough for heavy-duty use.

For bags that need to withstand the most wear and tear, nylon is the clear winner. If you’re aiming for lightweight or cost-effective options, polyester fits the bill. And for premium, aesthetic-focused designs, PU leather is the material of choice.

How can I customize team sports bags to reflect team branding?

Customizing team sports bags is a fantastic way to highlight team spirit while keeping things practical. Start by gathering key elements like your team’s logo, colors, mascot, and any extra text – think team name or the current season. Decide how you want these details showcased. For a high-end feel, embroidery works great, while screen printing offers bold, colorful designs.

Next, pick a bag style that suits your sport. Options like backpacks, duffle bags, or specialized totes are popular. Look for durable materials like polyester or water-resistant canvas to handle wear and tear. You can tweak the size, compartments, and layout of the bag to meet your team’s specific needs. Be strategic with your color placement on panels and trims, and consider adding personal touches like player numbers or sponsor logos to make the bags truly stand out.

Once you’ve finalized the design, request a prototype. This step ensures the final product matches your vision before committing to a bulk order. With this approach, your team bags will be both functional and a standout representation of your team’s identity.

What are the must-have features of a sports bag for team equipment?

A good sports bag for team equipment should balance functionality, durability, and versatility. Materials like nylon or polyester, especially if water-resistant, are ideal for keeping gear safe from rain and everyday wear. A well-designed bag will have spacious compartments – a large main section for items like uniforms and pads, along with smaller zippered or mesh pockets to store shoes, water bottles, or personal belongings.

Comfort matters too. Look for padded, adjustable straps that let you carry the bag as a backpack, duffel, or sling, depending on your preference. If your sport requires specific gear, bags with specialized compartments – like holders for tennis rackets, basketballs, or golf clubs – can make organization much easier. Reinforced bases and side panels ensure the bag can handle heavier equipment without damage. And for a touch of team spirit, consider customization options for logos, team colors, or even player names to make the bag uniquely yours.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD