Why does quality fail in custom bags? It often boils down to hidden issues in production – like poor materials, operator errors, or faulty equipment. Instead of patching symptoms, manufacturers need to dig deeper. This is where Root Cause Analysis (RCA) proves its worth. By identifying and fixing the actual causes, manufacturers can drastically reduce defects and improve reliability.

Principais conclusões:

- RCA helps identify why defects like seam failures, zipper malfunctions, or material inconsistencies occur.

- Common causes include supplier errors, untrained operators, or equipment failures.

- Methods like the 5 Whys e Fishbone Diagrams help trace problems to their roots.

- Reliable data – defect logs, material tests, and inspection reports – drives effective RCA.

- RCA strengthens supplier relationships, ensuring better materials and fewer recalls.

The result? Fewer defects, happier customers, and stronger trust in your products.

Finding and Analyzing Defects in Custom Bags

Typical Defects in Custom Bags

Defects in custom bags can include issues like variations in fabric shade, stains, holes, snags, misprints, and uneven dyeing. These flaws not only compromise product quality but also lead to increased waste and potential liability for manufacturers. For customers, receiving defective products can result in dissatisfaction, damage to brand reputation, and a loss of trust. Understanding these common defects is the first step in tracing them back to their sources within the supply chain and production process.

Connecting Defects to Supplier and Process Problems

To trace defects to their origins, it’s essential to consider three main root cause categories. Physical causes involve tangible issues, such as equipment malfunctions or substandard materials provided by suppliers. Human causes stem from mistakes or incorrect actions during production, while organizational causes highlight broader system or process failures.

For example, one manufacturer faced repeated production delays due to frequent machine stoppages. Upon investigation, root cause analysis (RCA) revealed the real issue: defective parts consistently supplied by an external vendor, not the machine itself.

In addition to supplier-related problems, defects can arise from inconsistencies in internal processes or lapses in quality control. For instance, fabric shade variations between batches may signal gaps in process oversight, allowing deviations from product standards to go unnoticed. Pinpointing these root causes enables manufacturers to gather actionable insights from defect data.

Using Defect Data for Root Cause Analysis

Reliable defect data is a cornerstone of effective RCA, helping manufacturers identify patterns and uncover underlying problems. Defect logs should capture key details such as what occurred, when and where it happened, who was involved, and the measurable impact on production or costs. Inspection reports and maintenance records are also invaluable for spotting fault trends and equipment-related issues.

Material testing plays a critical role in determining whether components like fabrics, zippers, or hardware meet required specifications. The effectiveness of any root cause analysis depends heavily on the accuracy and thoroughness of the collected data.

A "golden sample" – a signed reference unit representing the ideal product – serves as a benchmark for identifying deviations from expected quality standards. When analyzing defect data, manufacturers should pay attention to recurring patterns, such as clusters of defects during specific shifts or links to particular material batches or supplier deliveries. Recognizing these trends allows manufacturers to focus on addressing the root causes rather than just managing surface-level symptoms. These insights are instrumental in shaping corrective actions and refining supplier quality strategies, which will be explored in the next section.

How to Perform Root Cause Analysis in Manufacturing: Root cause analysis examples in manufacturing

RCA Methods for Bag Manufacturing

Root Cause Analysis Methods for Custom Bag Manufacturing

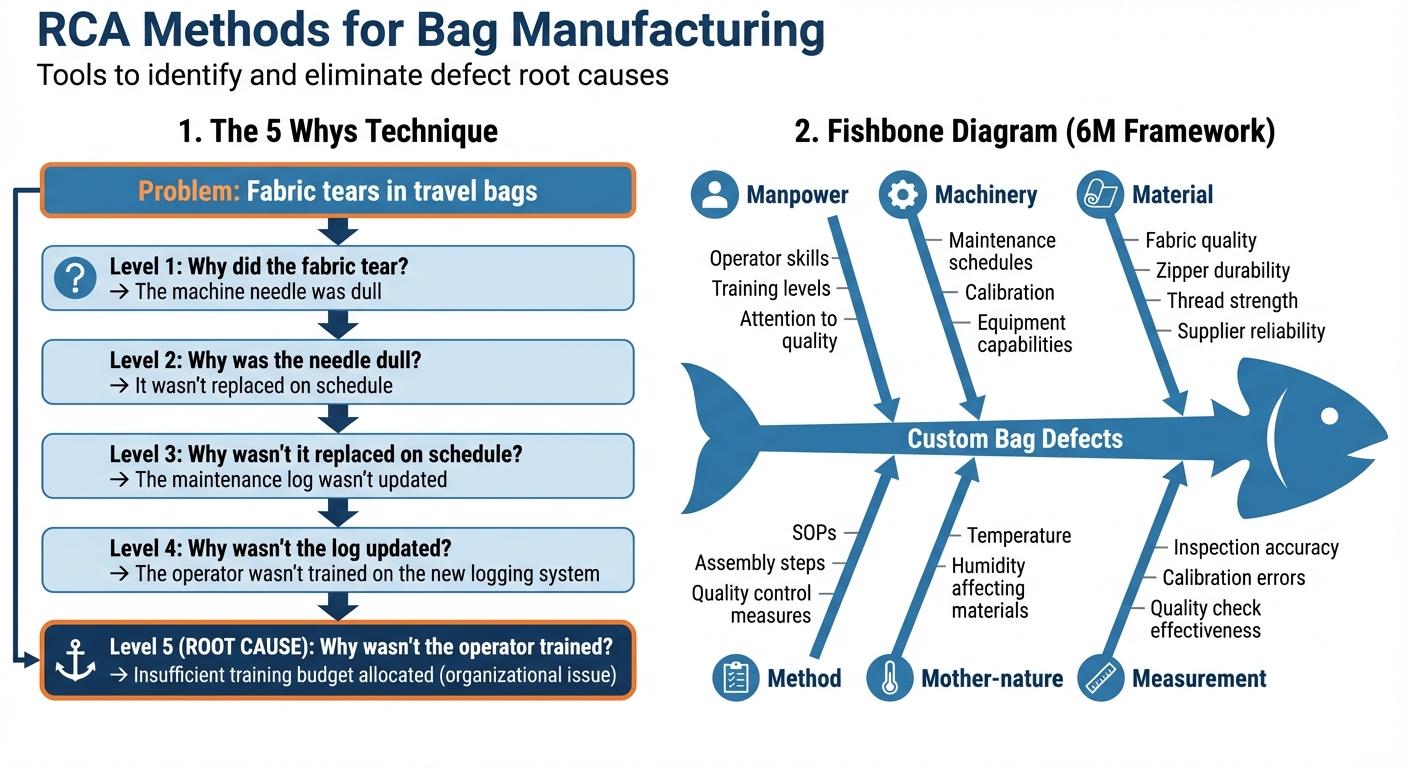

The 5 Whys Technique

The 5 Whys technique is a simple yet powerful method to uncover the root cause of a problem by repeatedly asking "why?" until the underlying issue is identified. Instead of stopping at surface-level explanations, this approach digs deeper to address the actual cause, ensuring long-term solutions. It’s a key tool in lean production and Six Sigma practices, focusing on improving processes rather than assigning blame.

To use this method, start with a clear problem statement, such as "15% of custom bags in lot #XYZ have failed zippers" or "fabric tears observed on the bottom panel." Then, ask "why?" multiple times to trace the issue back to its root cause. For instance, if fabric tears are found in travel bags:

- Why did the fabric tear? The machine needle was dull.

- Why was the needle dull? It wasn’t replaced on schedule.

- Why wasn’t it replaced on schedule? The maintenance log wasn’t updated.

- Why wasn’t the log updated? The operator wasn’t trained on the new logging system.

- Why wasn’t the operator trained? Insufficient training budget allocated (organizational issue).

This method helps manufacturers identify system-level failings rather than stopping at individual errors. The goal is to keep asking "why?" until you reach a cause that, once addressed, prevents the problem from happening again. To further clarify these connections, you can map them visually using a Fishbone Diagram.

Fishbone Diagrams for Bag Manufacturing

A Fishbone Diagram, also called a Cause and Effect or Ishikawa Diagram, is a visual tool that categorizes potential causes of a problem. It organizes these causes into groups, making it easier to see how they interconnect. The problem statement is placed at the "head" of the diagram, with a horizontal "backbone" and major cause categories branching off like "spurs".

For custom bag production, the 6M framework is particularly useful:

- Manpower: Operator skills, training levels, and attention to quality.

- Machinery: Maintenance schedules, calibration, and equipment capabilities.

- Material: Fabric quality, zipper durability, thread strength, and supplier reliability.

- Method: Standard operating procedures, assembly steps, and quality control measures.

- Mother-nature: Environmental factors like temperature and humidity affecting materials.

- Measurement: Accuracy of inspections, calibration errors, and effectiveness of quality checks.

To create the diagram, draw a horizontal arrow pointing to the right with the problem statement at the arrowhead. Add branches at an angle for each of the 6M categories, then list specific causes under each branch. You can apply the 5 Whys technique to these causes to drill down even further, turning broad categories into precise, actionable insights. Combined with accurate data collection, this approach is a powerful tool for effective root cause analysis.

Collecting Data for Effective RCA

Accurate and detailed data is the foundation of any successful root cause analysis. This includes defect photos, lot numbers, supplier records, and test results. A well-crafted problem statement should specify the product that failed, describe the failure in detail, quantify the number of defective units, and include customer feedback.

"Before you can complete a root cause analysis, you must collect as much data as possible about the events and people involved in the lead-up." – Tulip.co

For example, document defect photos that highlight the exact failure points, link lot numbers to production runs, and gather supplier records for materials used in the affected batches. Test results for fabric strength, zipper durability, or stitching quality can provide additional insights. Using the 5W/2H framework – Who was involved? What happened? When did it occur? Where was it detected? How did it fail? How many units were affected? Why did it happen? – ensures a comprehensive understanding of the issue.

"If you’re primarily basing your analysis on employee testimony, it’s important that you establish a framework for collecting hard data as soon as possible. People can be unreliable and their memories are vulnerable to suggestions, especially after time has passed." – Tulip.co

Incomplete or inaccurate data can derail the RCA process, leading to ineffective solutions. To avoid this, implement systems that collect real-time data from people, processes, and machines. This ensures faster, more reliable analysis and helps turn insights into actionable steps rather than guesswork.

sbb-itb-1e6451b

Connecting RCA with Supplier Quality Management

Root cause analysis (RCA) plays a critical role in managing supplier relationships, especially when issues like inconsistent fabric quality or incorrect webbing specifications arise. It’s not just about identifying problems; it’s about integrating these findings into supplier quality management practices, starting with clear performance metrics.

Measuring Supplier Performance

Supplier performance should be measured with specific, actionable metrics informed by RCA findings. Instead of broad evaluations, focus on concrete data like defect rates, delivery punctuality, and responsiveness to corrective actions. For instance, in custom bag manufacturing, this might mean tracking issues such as nylon webbing that doesn’t meet strength requirements, UV-resistant coatings that fail durability tests, or hardware components that break under stress.

Take this example: a custom bag manufacturer discovered recurring problems with webbing strength. RCA revealed the issue stemmed from mismatched material specifications. By adjusting supplier parameters, they reduced defect rates by 40%. These insights should feed into regular supplier reviews, enabling data-driven evaluations that guide decisions and improve quality over time.

Supplier Corrective Action Requests (SCARs)

If RCA pinpoints a supplier as the root cause of a problem, issue a formal Supplier Corrective Action Request (SCAR). This document should clearly outline the problem, root cause, required corrective actions, and deadlines. Include essential details like batch numbers, lot information, and the number of affected units, along with your initial RCA findings.

Suppliers, in turn, should conduct their own RCA – using tools like the 5 Whys or Fishbone diagrams – to confirm the root cause and create a corrective and preventive action (CAPA) plan. Track the SCAR process from start to finish, ensuring that suppliers implement effective solutions. Follow-up inspections and audits are vital to verify that the corrective actions prevent the issue from recurring.

Building Long-Term Supplier Partnerships

Sharing RCA findings openly with suppliers fosters collaboration rather than assigning blame. This transparency allows you to work together on preventive measures, such as joint audits, shared testing protocols, and continuous improvement initiatives. In custom bag manufacturing, this might involve collaborating on material specifications – like refining military-grade nylon standards, improving UV-resistant coating formulations, or enhancing stress-test protocols for hardware.

Proactive RCA techniques, such as Failure Mode and Effects Analysis (FMEA), can also be applied with suppliers to identify potential failure points before they happen. By prioritizing risks based on factors like severity, likelihood, and detectability, you can address problems before they escalate. This approach shifts the dynamic from a simple buyer-supplier relationship to a partnership where both parties share responsibility for quality outcomes.

Custom bag manufacturers, including SACOS DE JUNYUAN, use these RCA-driven strategies to cultivate strong supplier partnerships and maintain high-quality production standards. By integrating RCA into supplier management, businesses can ensure consistent quality and reliability across the supply chain.

Implementing and Verifying Corrective Actions

Once you’ve pinpointed the root cause of an issue, the next step is implementing CAPA (Corrective and Preventive Actions) to ensure the problem is resolved for good. Here’s how to take the insights from your RCA (Root Cause Analysis) and turn them into meaningful changes in custom bag manufacturing.

Turning Findings Into Process Changes

Start by crafting a clear, actionable plan that directly addresses the root cause. This could involve updating Standard Operating Procedures (SOPs) for stitching techniques, fine-tuning heat-press temperatures for logo application, or revising inspection protocols to focus on zipper alignment. Every adjustment, whether it’s a new SOP or an updated training program, should be thoroughly documented to maintain consistency.

It’s equally important to assign responsibility for each corrective action. Make sure the right people are accountable, provide adequate resources, and communicate changes to all relevant teams. For instance, if your RCA reveals that delamination issues stem from incorrect heat-sealing temperatures, update your SOPs to include precise temperature ranges and retrain operators accordingly. Before rolling out changes on a large scale, consider pilot testing them on a smaller production run. This allows you to evaluate the cost, feasibility, and long-term impact of the adjustments without risking the entire operation.

Working with Suppliers on Preventive Measures

If your RCA points to problems with supplier-provided materials, it’s time to collaborate with your suppliers. For example, if defective materials are causing bag malfunctions, work with suppliers to align material specifications more closely with your requirements. This could significantly reduce defects in components like webbing, zippers, buckles, or fabric coatings.

Beyond specifications, focus on improving packaging standards and handling practices with your suppliers. By doing so, you shift the relationship from a simple transaction to a strategic partnership aimed at shared quality goals.

Validating and Monitoring Corrective Actions

Validation is key to ensuring your corrective actions work as intended. Define measurable Key Performance Indicators (KPIs) – such as defect rates, downtime reduction, or cost savings – to track their effectiveness. For instance, Factored Quality once conducted an RCA and CAPA for a brand, identifying specific manufacturing steps that compromised product quality. After implementing their recommendations, the defect rate dropped immediately, and detailed inspection checklists confirmed the problem was resolved.

Assign follow-up responsibilities and incorporate these checks into your SOPs. Monitor results consistently by comparing current performance against SMART targets. For example, you might aim to reduce zipper defect rates from 20% to 5% in one month, and then to 2% within three months. Regular reviews and audits help ensure that corrective actions become a permanent part of your processes. This approach not only fixes the immediate issue but also builds a culture of ongoing improvement throughout your manufacturing operations. Continuous monitoring ensures that you’re addressing problems at their source, rather than applying temporary fixes.

Conclusion: Using RCA for Continuous Improvement

Root Cause Analysis (RCA) fosters a manufacturing environment that thrives on continuous improvement. By identifying and addressing the root causes of defects, you create a ripple effect that enhances processes across your entire organization. A standardized RCA approach shifts the focus from reactive problem-solving to proactive, consistent quality improvements.

Creating a Continuous Improvement Plan

Each RCA you conduct should directly contribute to your continuous improvement plan. The insights gained lay the groundwork for process updates, revised standards, and new procedures designed to prevent future issues. This could involve refining employee training programs to close skill gaps, adopting technology to automate quality checks, or revising supplier specifications to eliminate material defects. For instance, a custom bag manufacturer used RCA to investigate repeated zipper defects and uncovered inconsistent quality control at the supplier level. By introducing stricter supplier inspection protocols, they significantly reduced defect rates.

Make RCA a standard practice for addressing recurring quality issues and specific types of failures, particularly those linked to suppliers. Incorporate RCA findings into your corrective and preventive action (CAPA) systems, design reviews, and process validation efforts. This systematic approach transforms isolated fixes into a cohesive strategy for ongoing improvement. These improvements not only streamline operations but also strengthen your quality certifications and build customer confidence.

How RCA Supports Certifications and Customer Trust

Consistent RCA practices also play a key role in securing ISO 9001 certification and reinforcing customer trust. Quality management certifications require organizations to document corrective actions and demonstrate a commitment to continuous improvement. Companies that excel in problem-solving through RCA earn stronger reputations and foster greater customer confidence.

The stakes couldn’t be higher: nearly 75% of manufacturers have faced a product recall in the past five years, with each recall costing millions. In 2022 alone, over 1.5 billion units were recalled across various industries. For custom bag manufacturers, robust RCA practices are essential – not just for operational efficiency but also for meeting strict industry certifications and maintaining customer trust. Implementing rigorous RCA processes helps prevent defective products, reduces recall risks, and protects your reputation. When customers see your commitment to solving problems at the source, they gain confidence in your ability to deliver consistent quality. That trust translates into stronger relationships and long-term business growth.

FAQs

How can Root Cause Analysis help improve relationships with suppliers in custom bag manufacturing?

Root Cause Analysis (RCA) helps custom bag manufacturers dig deep to uncover the real reasons behind quality issues. By identifying these underlying causes, manufacturers can collaborate with suppliers to create specific solutions, cutting down on defects and enhancing the quality of their products.

This teamwork doesn’t just fix problems – it fosters trust and openness between manufacturers and suppliers. Addressing issues at their core helps prevent them from happening again, paving the way for stronger partnerships and more efficient production workflows.

What are the main techniques for identifying quality issues in custom bag manufacturing?

Improving quality in custom bag manufacturing requires a thoughtful approach. One useful technique is Process Mapping, which lays out every step in production, making it easier to spot where defects might arise. Another proven method is the 5 Whys, where you repeatedly ask "why" to dig deep and uncover the root cause of an issue. Additionally, the Plan-Do-Study-Act (PDSA) cycle allows manufacturers to test solutions, analyze the outcomes, and make adjustments for better results. Together, these strategies help manufacturers enhance product quality and make production more efficient.

Why is accurate data collection important for solving quality issues in manufacturing?

Accurate data collection plays a critical role in uncovering the real root causes behind quality problems in manufacturing. Without dependable and complete data, identifying the exact issue becomes a guessing game, making it tough to implement effective fixes.

When manufacturers focus on collecting precise data, they can tackle recurring problems head-on, cut down on downtime, and save money. This approach not only boosts efficiency but also enhances the quality of the final product.

Telemóvel/What's App/Wechat

Telemóvel/What's App/Wechat E-Mail

E-Mail ADD

ADD