BSCI compliance focuses on improving working conditions and responsible practices across supply chains. It’s not a one-time certification but a continuous framework that evaluates labor rights, workplace safety, ethics, and environmental standards. Major buyers like H&M and Aldi require suppliers to meet these criteria, making compliance essential for manufacturers targeting European and North American markets.

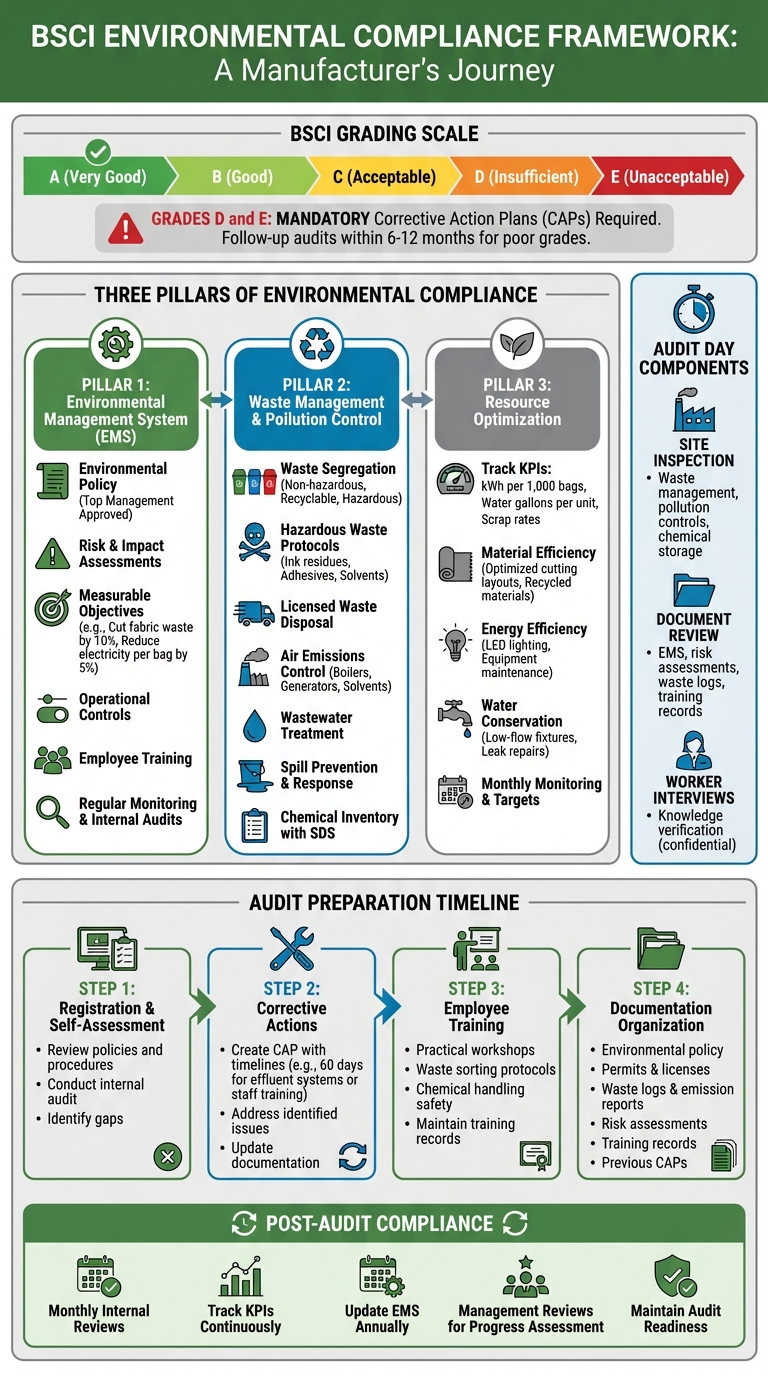

When it comes to environmental standards, BSCI emphasizes reducing waste, managing emissions, and handling hazardous substances responsibly. For manufacturers, this means implementing systems like waste segregation, chemical safety protocols, and efficient resource use. Auditors assess these practices through site inspections, document reviews, and employee interviews, grading facilities from A (very good) to E (unacceptable).

Key steps for compliance include:

- Establishing a risk-based Environmental Management System (EMS).

- Ensuring legal compliance with permits and regulations.

- Training employees on waste handling and chemical safety.

- Documenting waste, emissions, and energy use for audits.

For industries like bag manufacturing, aligning with BSCI standards not only meets buyer expectations but also improves production efficiency and reduces costs. Regular monitoring, internal reviews, and setting measurable goals ensure continued compliance and operational improvements.

BSCI Environmental Compliance Process: From EMS Setup to Audit Success

Core Environmental Requirements Under BSCI

Legal Compliance and International Standards

Manufacturers working under BSCI guidelines must comply with all applicable environmental laws, including those related to emissions, waste disposal, hazardous materials, and necessary permits. For bag production, this involves following strict rules on the use of textile dyes, plastics, and chemicals. Although BSCI is not the same as ISO 14001 certification, adopting a risk-based Environmental Management System (EMS) inspired by ISO 14001 helps manufacturers systematically manage environmental risks and demonstrate compliance.

In addition to meeting legal requirements, BSCI encourages companies to actively reduce their environmental impact. This includes minimizing waste, controlling emissions, and eliminating hazardous substances from their processes. If audits uncover issues, companies are required to implement a Corrective Action Plan (CAP) with clear deadlines and undergo follow-up audits within 6 to 12 months to ensure improvements are made.

This combination of legal and operational expectations provides a strong foundation for the detailed evaluations that take place during audits.

What Auditors Look for in Environmental Policies

During a BSCI audit, evaluators focus on how well a facility’s environmental policies and procedures address its operational impacts. They review documentation, inspect the site, and interview employees to ensure environmental practices are integrated into day-to-day operations.

Auditors examine key documents such as environmental policies, EMS procedures, compliance registers, waste management records, emission logs, and past CAPs. They also check the validity of permits and assess whether pollution prevention efforts – like reducing emissions or implementing proper waste segregation – are delivering measurable results.

The audit process prioritizes real-world outcomes over paperwork alone. Facilities are graded on a scale from A (very good) to E (unacceptable). Receiving a D or E triggers the need for mandatory corrective actions. Common issues flagged during audits include poor waste segregation, missing emission permits, or unmonitored chemical storage. These problems must be addressed through CAPs with specific deadlines – for instance, installing effluent treatment systems or conducting staff training within 60 days.

Setting Up an Environmental Management System (EMS)

Key Components of an EMS

An Environmental Management System (EMS) provides manufacturers with a structured way to manage their environmental impact. At its foundation is an environmental policy, approved by top management, that commits the organization to comply with regulations and strive for ongoing improvement. This policy typically outlines the company’s goals for reducing waste, controlling emissions, and using resources more efficiently.

The next step involves conducting risk and impact assessments for every stage of production – whether it’s cutting, printing, sewing, or packaging. For example, in bag manufacturing, this means evaluating factors like waste, emissions, water and energy usage, and noise levels. The EMS should also include clear, measurable objectives, such as cutting fabric waste by 10% within a year or reducing electricity usage per bag by 5% over the same period. These goals should come with assigned responsibilities and deadlines.

To ensure smooth daily operations, operational controls are critical. These might include procedures for waste segregation, proper chemical storage, spill response protocols, and routine equipment maintenance. Employee training is another key element – staff handling inks, adhesives, or solvents must follow established safety protocols. Additionally, regular monitoring metrics, such as waste output or energy consumption, help track progress. Internal audits and management reviews allow companies to evaluate the EMS’s effectiveness and pinpoint areas for improvement.

Once these EMS components are in place, the focus shifts to identifying and managing the environmental risks tied to production processes.

Identifying and Managing Environmental Risks

Each step of production should be mapped out to identify its environmental impacts – such as scrap waste, solvent emissions, wastewater, noise, and energy use. These impacts should then be assessed based on legal, health, and volume criteria. For instance, solvent-based printing might pose a high risk due to air quality regulations and health concerns, while excessive non-recyclable packaging can significantly add to waste. Risks that pose the greatest threat to compliance or the environment – like improper chemical storage, unpermitted boiler emissions, or inefficient cutting methods leading to fabric waste – should be prioritized.

To manage these risks effectively, create a risk register. This document should detail each risk, its severity rating, current controls in place, and any actions needed to mitigate it. The register should be reviewed and updated annually or whenever major changes occur, such as the introduction of new materials or an expansion in production capacity.

Required Documentation and Records

Thorough documentation is essential for demonstrating the EMS’s effectiveness. Auditors will look for records that show the system is actively improving environmental performance. Start with legal compliance records, such as permits, inspection reports, and evidence of corrective actions for any violations.

Maintain and regularly update the risk assessment and aspect/impact register. Pair this with clearly defined objectives and improvement plans that document progress, like reductions in waste or energy use per unit produced. Monitoring records – such as logs for energy and water consumption, emission reports, waste manifests, and maintenance records for pollution-control equipment – serve as concrete proof of these efforts.

Training records are equally important. These should confirm that employees managing chemicals, waste, and environmental controls have received proper instruction. Keep attendance logs and training outlines on file. Any incidents, such as spills, must also be documented along with root cause analyses and the corrective actions taken. Lastly, internal EMS audit reports and management review minutes should be organized in clearly labeled digital or physical folders to ensure the system is regularly assessed and improved.

At SACOS DE JUNYUAN, these EMS practices are embedded in daily operations, helping to minimize environmental impacts while staying compliant with BSCI standards.

Waste Management and Pollution Control

Handling Waste in Bag Production

To meet BSCI compliance, manufacturers must adopt effective waste management strategies throughout the production process. This involves sorting waste into categories such as non-hazardous (e.g., fabric scraps, foam, webbing offcuts), recyclable, domestic, and hazardous materials. Clearly labeled, color-coded containers should be placed strategically at key production areas like cutting tables, sewing stations, printing zones, and packing areas.

Hazardous waste, including ink residues, adhesive containers, oily rags, and solvent-contaminated materials, requires special handling. It should be stored in secure, leak-proof containers within a designated, ventilated area equipped with spill trays. Maintaining an up-to-date inventory and Safety Data Sheets (SDS) is essential. Disposal of hazardous materials must be done through licensed waste contractors, and all contracts, manifests, and receipts should be retained as proof of proper disposal.

Tracking waste metrics is crucial for assessing progress. Waste can be minimized at the source by improving cutting layouts, standardizing panel sizes, and repurposing scraps for components like pockets or internal organizers. Packaging waste can be reduced by replacing single-use plastics with recyclable options and designing cartons that better fit product dimensions. At JUNYUAN BAGS, waste-reduction strategies are integrated into the design phase, ensuring efficient use of materials and minimizing scrap rates even before production begins.

These practices lay the groundwork for effective pollution control measures.

Reducing Pollution from Manufacturing

Pollution control in bag production focuses on managing air emissions, wastewater, and chemical safety. Key sources of pollution include boilers, generators, solvent use in printing or coating, wastewater from cleaning processes, and chemical storage areas. To address these, manufacturers should maintain boilers and generators with proper filters and ventilation, install local exhaust systems for solvent-heavy areas, and pre-treat wastewater to meet discharge permit requirements. Keeping organized records of test results, permits, and maintenance schedules ensures readiness for audits.

Preventing spills is equally important. Secondary containment measures, such as spill trays under drums and containers, protect floor drains and outdoor areas. Clear spill-response procedures, complete with spill kits, absorbents, and assigned cleanup responsibilities, help manage incidents effectively. Documenting spills and corrective actions demonstrates active pollution control efforts.

A current chemical inventory with SDS and hazard classifications is essential. Replacing hazardous substances with safer alternatives – like low-VOC adhesives or water-based inks – can significantly reduce risks. Proper storage and mixing practices further enhance safety. To manage noise and dust from operations like cutting or sanding, local exhaust systems, enclosures, and appropriate personal protective equipment (PPE) should be used to meet regulatory thresholds and minimize community impact.

By addressing pollution at its source, manufacturers can align these efforts with broader resource optimization goals.

Optimizing Resource Use

Efficient resource use ties directly to BSCI compliance and cost savings. Key performance indicators (KPIs), such as energy use (kWh per 1,000 bags), water consumption (gallons per unit), and scrap rates, help track progress and highlight areas for improvement. Material efficiency can be enhanced by optimizing cutting layouts, standardizing pattern sizes, and nesting components to reduce waste. Using recycled or certified materials, like recycled polyester, where acceptable to buyers, can also lessen the environmental impact of raw material sourcing.

Energy efficiency can be improved by installing LED lighting, enhancing insulation, and regularly maintaining equipment like compressors and sewing machines. Scheduling energy-intensive operations during off-peak hours and upgrading to high-efficiency motors can further reduce costs. Water usage can be minimized by installing low-flow fixtures, fixing leaks promptly, and reusing process water for tasks like rinsing or cleaning where possible. Monitoring energy and water consumption monthly provides insights into trends and helps set realistic reduction targets for audits.

Assigning clear environmental responsibilities and setting annual efficiency goals – such as a 5% reduction in fabric waste – keeps teams focused. Displaying monthly KPI dashboards and sharing performance updates with employees ensures they understand how their actions, like proper waste segregation or turning off machinery when not in use, contribute to both audit readiness and the factory’s global competitiveness.

sbb-itb-1e6451b

What is BSCI Certification? | A Clear Guide to the amfori Iniciativa de Conformidade Social das Empresas

Preparing for a BSCI Environmental Audit

At JUNYUAN BAGS, environmental responsibility is woven into every step of our bag manufacturing process. We follow a detailed plan to ensure our operations align with the BSCI Code of Conduct, often going beyond the basic requirements.

Audit Preparation Steps

Preparing for a BSCI environmental audit starts with registration and self-assessment. This involves reviewing company policies, procedures, and records to ensure they meet the BSCI Code standards. Conducting an internal audit at this stage is crucial. It helps identify potential issues early, such as improper waste segregation at cutting stations or missing Safety Data Sheets for adhesives, so these can be addressed promptly.

Once gaps are identified, create a Corrective Action Plan (CAP) with clear timelines for resolution. Employee training is equally vital. Organize practical workshops where workers learn the ins and outs of environmental responsibilities, such as sorting fabric scraps, safely handling chemicals, and reporting spills. Keep detailed records of these sessions, including attendance sheets and signed acknowledgments.

Thorough documentation is key. Track all environmental aspects, from waste streams to air emissions, ensuring compliance with both local laws and BSCI requirements. Verify that all permits and licenses – like wastewater discharge approvals or hazardous waste registrations – are up to date and easily accessible. Maintain a well-organized system for storing critical documents, including your environmental policy, inspection reports, waste disposal records, and monitoring logs. These steps lay the groundwork for a successful audit.

What to Expect During an Environmental Audit

During the audit, BSCI auditors focus on three main areas: site inspections, document reviews, and worker interviews. During site inspections, auditors observe waste management practices, ensuring, for instance, that fabric scraps and packaging materials are properly sorted and stored. They also check pollution controls, such as ventilation systems in areas where solvents are used. Chemical storage areas must meet strict standards, with secondary containment, clear labeling, and spill kits readily available. Auditors also look out for any signs of illegal dumping or hazardous spills.

The document review is equally thorough. Auditors examine your Environmental Management System (EMS), risk assessments, waste logs, training records, and any previous Corrective Action Plans. Disorganized or outdated records can lead to lower scores, so keeping everything current and well-maintained is critical. Worker interviews are another important component. These confidential discussions help auditors verify whether employees understand key practices, such as proper chemical handling and waste segregation. In the bag manufacturing industry, questions often touch on topics like sustainable material sourcing, hazardous waste protocols for adhesives or inks, and efforts to improve resource efficiency.

The audit wraps up with a grade ranging from A (outstanding) to E (unacceptable) across 13 performance areas, including environmental protection. Grades below C require mandatory corrective actions and usually trigger a follow-up audit within 6–12 months. Common pitfalls include poor ventilation, inadequate recycling systems, or missing documentation – issues that can often be avoided with thorough preparation.

Maintaining Compliance Over Time

After the audit, staying compliant means committing to ongoing monitoring and improvement. Conduct monthly internal reviews and track key performance indicators (KPIs) like waste reduction, energy usage per unit produced, or water consumption per unit. These metrics help ensure timely follow-up on any corrective actions and keep your operations on track during the 6–12 month follow-up period.

Regular updates to your Environmental Management System are essential. Incorporate employee feedback and insights from internal audits into your annual revisions. Many manufacturers align their BSCI compliance efforts with standards like ISO 14001 to meet the expectations of U.S. and European buyers who prioritize both social and environmental responsibility. Holding regular management reviews to assess progress on environmental goals and adjust strategies demonstrates that compliance is an integral part of your operations – not just a box to check. This ongoing dedication not only ensures audit readiness but also strengthens relationships with buyers, building trust and long-term partnerships.

Conclusão

BSCI environmental criteria aren’t just a box to check – they serve as a guide for embedding responsible and efficient manufacturing practices into daily operations. By adopting a risk-based Environmental Management System, managing waste effectively, controlling emissions, and using resources wisely, bag manufacturers can not only meet compliance requirements but also cut costs and minimize operational risks. These efforts translate into tangible benefits like reduced material usage, lower energy bills, and decreased waste disposal expenses.

Beyond operational gains, BSCI compliance is increasingly critical as many buyers in Europe and the U.S. demand verified environmental performance from their suppliers. For manufacturers like JUNYUAN BAGS, showcasing environmental improvements – such as minimizing fabric waste with better cutting techniques or reducing VOC emissions through enhanced ventilation systems – can provide a competitive edge when securing supplier contracts and preparing sustainability reports.

The secret lies in integration. Environmental controls shouldn’t be siloed as audit prep but should be part of every aspect of operations – procurement, production planning, maintenance, and waste management. Steps like mapping waste streams, setting clear, measurable goals (e.g., cutting scrap rates or reducing energy use per unit), and conducting regular on-site reviews help factories stay audit-ready while driving continuous improvement.

FAQs

What are the main environmental criteria for BSCI compliance?

The main focus of BSCI compliance in environmental standards revolves around three critical areas: waste management, resource efficiency, and pollution control.

A well-implemented Environmental Management System (EMS) ensures proper handling and disposal of waste, promotes efficient use of resources like water and energy, and includes measures to reduce pollution affecting air, water, and soil. These efforts not only align with BSCI requirements but also support more sustainable and environmentally conscious operations.

What are the cost and efficiency benefits of BSCI compliance for manufacturers?

BSCI compliance helps manufacturers cut costs through better waste management, smarter use of resources, and fewer pollution-related fines. These measures simplify operations, eliminate unnecessary expenses, and encourage more responsible production methods.

Following BSCI’s environmental guidelines also improves operational efficiency. By using resources wisely, manufacturers can reduce waste and avoid production hiccups, resulting in smoother workflows and lower overall costs.

How can manufacturers prepare for a BSCI environmental audit?

Getting ready for a BSCI environmental audit means paying close attention to compliance in several important areas. Begin by gathering and organizing all necessary documents, like records detailing waste management practices and initiatives aimed at improving resource efficiency. Make sure your pollution control measures are not only in place but also consistently maintained.

It’s equally important to train your team on environmental protocols so everyone is clear about their responsibilities in meeting compliance standards. Performing internal audits ahead of time can help you pinpoint and fix any issues before the official review. Taking these proactive steps shows your dedication to meeting environmental standards while making the audit process smoother.

Telemóvel/What's App/Wechat

Telemóvel/What's App/Wechat E-Mail

E-Mail ADD

ADD