NOCSAE standards ensure sports gear like helmets and chest protectors meet safety benchmarks, but improper storage or transport can damage this equipment, voiding its certification. Custom sports bags play a key role in protecting certified gear by preventing compression, deformation, or heat exposure during transit. Manufacturers should design bags with padded compartments, rigid panels, and ventilation while avoiding features that alter or damage equipment.

Key takeaways:

- NOCSAE standards apply to sports gear, not bags, but bags must protect certified equipment.

- Poorly designed bags can compromise safety by deforming or damaging gear.

- Features like reinforced compartments, ventilation, and moisture resistance are critical.

- Custom branding should avoid interfering with protective elements.

What Safety Standards Does NOCSAE Certification Cover?

NOCSAE Standards and Their Impact on Bag Design

NOCSAE Standards and Custom Sports Bag Design Requirements by Equipment Type

What NOCSAE Standards Cover

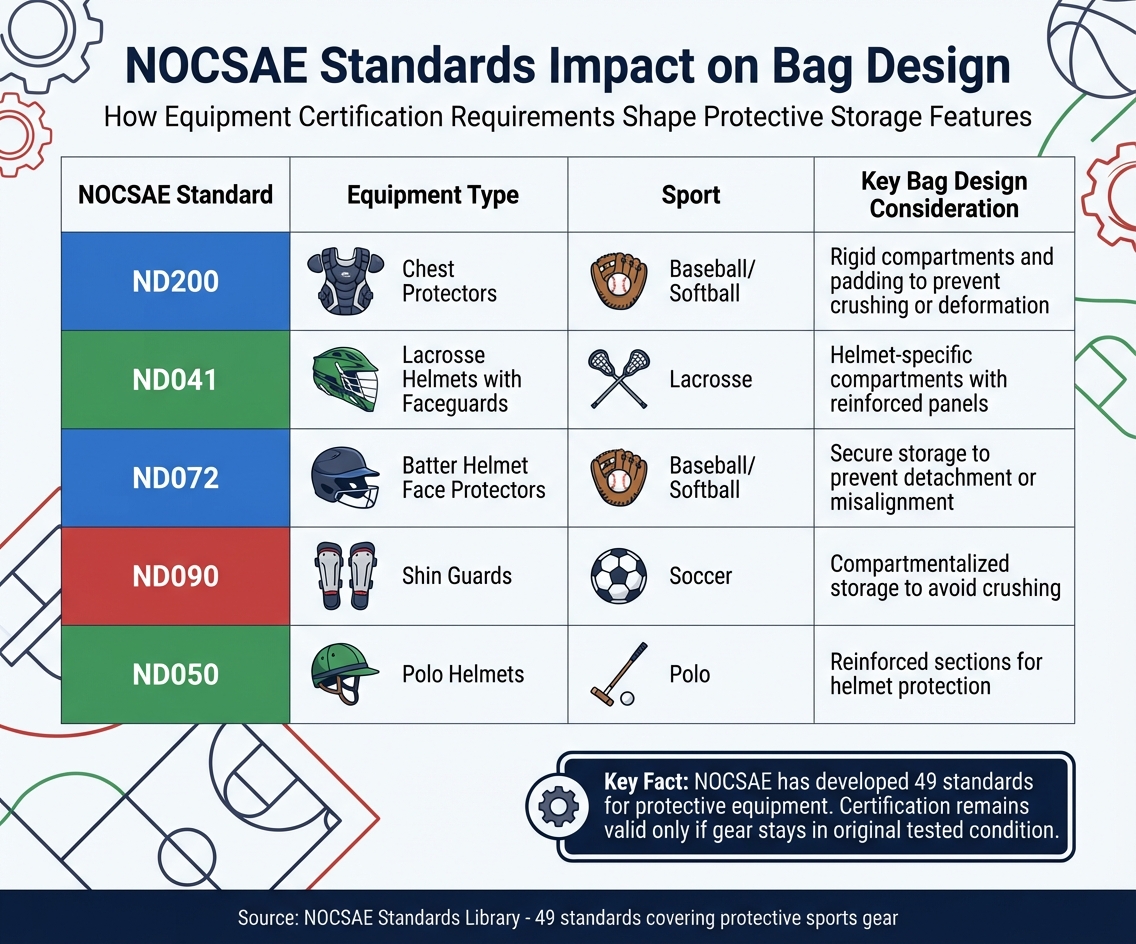

O National Operating Committee on Standards for Athletic Equipment (NOCSAE) is responsible for creating performance and testing standards for protective sports gear. However, these standards don’t directly apply to the bags that carry such equipment. NOCSAE has developed 49 standards covering items like football helmets, baseball chest protectors, lacrosse faceguards, and soccer shin guards. These standards focus on impact resistance, using metrics like peak g-forces and impact duration to minimize injury risks.

While NOCSAE establishes the performance criteria, independent organizations such as the Safety Equipment Institute (SEI) handle certification. Even though bags aren’t certified, they play a critical role in preserving the condition of certified equipment. Certification is valid only if the gear remains in the same condition and configuration as when it was tested. This means bag designers must prioritize features that protect equipment during transport.

NOCSAE Standards That Affect Bag Design

To ensure NOCSAE-certified equipment stays in proper condition, specific standards indirectly shape how sports bags are designed. For example, storage and protective features in bags often reflect the requirements of these equipment standards.

Take ND200, which applies to chest protectors and became mandatory for high school and college baseball on January 1, 2020. This standard aims to prevent commotio cordis, a potentially fatal heart rhythm disturbance caused by chest impacts. If a chest protector is crushed or bent inside a poorly designed bag, it might fail to meet ND200 standards. That’s why custom bags for catchers and lacrosse goalies often include rigid or semi-rigid compartments with impact-absorbing padding around chest protector zones.

Helmet standards pose similar challenges. Standards like ND041 for lacrosse helmets with faceguards, ND072 for baseball/softball batter helmet face protectors, and ND050 for polo helmets require helmets to pass controlled impact tests and remain unaltered from their certified state. Tight compartments in a poorly designed bag can deform helmet padding or crack the shell, which could void certification. Even minor damage or alterations can invalidate certification. To address this, bag manufacturers design helmet compartments with reinforced panels, interior padding, and ample space to prevent compression during travel.

These considerations directly influence the design of custom sports bags.

| NOCSAE Standard | Equipment Type | Sport | Key Bag Design Consideration |

|---|---|---|---|

| ND200 | Chest Protectors | Baseball/Softball | Rigid compartments and padding to prevent crushing or deformation |

| ND041 | Lacrosse Helmets with Faceguards | Lacrosse | Helmet-specific compartments with reinforced panels |

| ND072 | Batter Helmet Face Protectors | Baseball/Softball | Secure storage to prevent detachment or misalignment |

| ND090 | Shin Guards | Soccer | Compartmentalized storage to avoid crushing |

| ND050 | Polo Helmets | Polo | Reinforced sections for helmet protection |

Designing Custom Sports Bags to Protect NOCSAE-Certified Equipment

Determining Which Equipment the Bag Will Carry

Before diving into the design, it’s crucial to identify the specific NOCSAE-certified equipment the bag will hold. Start by consulting the NOCSAE standards library and guidelines from organizations like NFHS, NCAA, NFL, and USA Lacrosse. These resources outline the required gear for various sports and competition levels. For instance, as of January 1, 2020, high school and college baseball catchers are required to use NOCSAE-certified chest protectors, while lacrosse players need helmets and faceguards that meet specific standards.

Create an equipment map tailored to the sport. This map should list each certified item, including its dimensions, weight (in pounds), and any necessary accessories like chin straps, faceguards, or padding. For multi-sport or team bags, break the list down by player roles, such as goalie versus field player, and note if the organization uses recertified equipment with additional labeling. This detailed mapping serves as the foundation for designing a bag that accommodates the equipment in its functional configuration.

Required Design Features for Protective Bags

Once the equipment is identified, the focus shifts to designing a bag that offers robust protection. Start with padded compartments that use foam or multi-layer padding to shield critical areas of helmets and chest protectors, such as the crown, sides, and front. Add semi-rigid panels – made from materials like HDPE or lightweight composites – on the base, ends, and lid to prevent crushing when gear is stacked in car trunks or bus cargo holds.

To keep equipment secure during transit, incorporate features like cradles, cinch straps, or molded forms that stabilize helmets and prevent heavy items, such as bats, from shifting and damaging certified gear. Include sacrificial crumple zones on the bag’s corners to absorb impacts from drops.

Moisture resistance and ventilation are equally vital. Use water-repellent fabrics, sealed seams, and coated linings to protect against rain or wet fields. Add ventilation ports or mesh panels to promote airflow around helmets and chest protectors, even when the bag is lying flat. Light-colored exteriors can help reduce heat buildup from sunlight, and care labels should advise users against storing the bag in vehicle trunks during extreme summer temperatures.

Testing Bag Prototypes with NOCSAE Equipment

After finalizing the bag’s design, rigorous testing ensures it meets protective standards. Start with static load tests to verify that the bag prevents compression of the equipment. Load the prototype with all relevant certified items and check that shells, padding, and faceguards remain intact and uncompressed. Certification labels and hardware should remain visible and undamaged in every suggested packing configuration.

Next, perform transport simulations. Drop the fully loaded bag from heights of 2 to 4 feet onto surfaces like concrete or turf to mimic real-world handling. Stack additional gear on top to replicate conditions in bus or car storage. Vibration tests can simulate the stresses of vehicle transport. After each test, inspect the equipment for cracks, dents, misalignment, or other signs of damage. For worst-case scenarios, overload specific compartments to confirm that the bag’s structure keeps the equipment safe and within acceptable deformation limits. Document all results in a detailed protocol to ensure consistent testing, especially if design adjustments are made.

Finally, ensure that internal components – such as stiffeners, rivets, or compression straps – don’t press against critical areas like helmet crowns, faceguard mounts, or padding systems. Since NOCSAE certification applies only to unaltered equipment, the bag design must not require permanent modifications, adhesives, or additional hardware on the gear. Review the bag’s care instructions to confirm they align with official recommendations, avoiding practices like prolonged compression or exposure to extreme heat that could void warranties or compromise certified performance.

sbb-itb-1e6451b

Adding Customization While Maintaining Protection Standards

Placement of Custom Branding and Logos

When adding custom branding to NOCSAE-certified equipment bags, it’s important to ensure logos and decorations don’t interfere with protective structures. The safest areas for branding include exterior zones like the front panel, side gussets, top flaps, shoulder straps, or end caps. These sections don’t serve as impact-absorbing components, so they can be customized without compromising safety during transport.

Avoid placing heavy embroidery on padded compartments, helmet cradles, or rigid panels. Large embroidered designs can stiffen fabrics, potentially creating pressure points that press against the equipment when the bag is fully loaded or stacked. For areas close to protective structures, opt for lighter decoration methods like screen printing, heat transfers, or sublimation, which add minimal thickness and preserve the integrity of foam padding. This approach ensures compliance with safety standards while still showcasing your branding.

It’s also essential to keep decorations away from ventilation ports or mesh panels designed to improve airflow around helmets and chest protectors. For example, on a lacrosse bag with a helmet compartment, place team logos on the exterior side panel instead of over the ventilated section. Similarly, for baseball catcher bags, embroidery should be positioned on the shoulder strap or end cap, steering clear of areas like the chest protector slot where added thickness could cause unwanted compression during storage.

Partnering with Custom Bag Manufacturers

Once you’ve identified the best branding locations, the next step is to collaborate with professionals who specialize in custom bag design. Working with experienced manufacturers ensures that your branding is integrated without affecting compliance. For instance, SACOS DE JUNYUAN (https://junyuanbags.com) offers expertise in creating custom sports bags for various activities, including golf, pickleball, tennis, baseball, basketball, and hockey. They provide options for custom logo placement while maintaining the protective features essential for certified equipment.

Manufacturers like JUNYUAN BAGS use tools like CAD mockups and prototype testing to confirm that branding doesn’t interfere with the bag’s protective structures. They also source high-quality materials, such as water-repellent nylon e polyester with padding, which combine durability with customization options. By collaborating during the design process, you can specify logo placement, choose decoration methods, and ensure there’s enough clearance around helmet cradles and rigid panels. This partnership not only ensures your branding looks great but also guarantees that the bag meets protective standards, keeping valuable equipment safe during transport and storage.

Maintaining Compliance and Informing Buyers

Once the design and testing phases are complete, the next step is ensuring compliance through thorough internal checks and clear, user-friendly instructions.

Creating Internal Compliance Checklists

Internal checklists are a practical way to maintain performance and ensure compliance throughout a product’s lifecycle. At the design stage, confirm which components are required to meet NOCSAE standards for items like football, baseball, and lacrosse helmets, chest protectors, and shin guards. Document any design choices that might affect certified gear, such as clamps or straps that could alter the original configuration. During production, verify that helmet compartments are spacious enough to avoid shell distortion, check padding density and placement, and ensure that the bag’s interior materials – like adhesives or coatings – won’t degrade the plastics or foams of certified equipment. At the final inspection stage, quality control should confirm that all compartments are correctly assembled and that no printed materials falsely suggest the bag itself is NOCSAE certified.

A well-rounded checklist should address these three areas:

- Product design: Confirm that compartments securely hold gear in its certified configuration without requiring users to remove original components.

- Materials and construction: Ensure seams, zippers, and dividers near protective gear are padded or shaped to prevent cracking or deformation.

- Communication and labeling: Clearly state that the bag is "designed to store and transport NOCSAE-certified equipment properly", while avoiding any claims that the bag itself is certified.

Manufacturers like JUNYUAN BAGS can integrate these checks into CAD design reviews, sample approvals, and pre-shipment inspections, requiring team sign-offs before shipping any custom orders.

Including Care Instructions for End Users

Clear, straightforward care instructions are crucial for helping buyers understand that NOCSAE certification applies to the equipment – not the bag – and remains valid only if the gear stays in its original configuration without unauthorized changes. Use simple, non-technical language and concise bullet points to convey these guidelines:

- Avoid compressing padding: Don’t stack heavy items on top of helmets in confined compartments for long periods.

- Keep away from extreme heat: Don’t leave a loaded bag in a car exceeding 90°F, as high temperatures can damage plastics and foams.

- No aftermarket modifications: Avoid attaching accessories, sensors, or extra padding to helmets while in the bag, as this could void NOCSAE certification by altering the equipment.

- Stick to recertification schedules: For sports requiring periodic recertification (like football, baseball, or lacrosse), remove equipment regularly for inspection of shells, padding, and hardware.

To make these instructions even clearer, pair the text with icons (e.g., "no crushing", "no heat", "check recertification dates", and "no alterations"). Use U.S. measurements (inches, °F) to ensure clarity for American buyers.

These care instructions, combined with proper labeling, help users maintain the integrity of their certified equipment.

Labeling and Documentation Requirements for U.S. Buyers

Labels should clearly differentiate between certified equipment and the bag itself. Use language like "Designed to accommodate and protect NOCSAE-certified helmets and pads in their manufacturer-approved configuration" or "Optimized for storage and transport of equipment certified to NOCSAE standards by SEI or other accredited certifiers." Avoid phrases such as "NOCSAE certified bag" or "NOCSAE-approved", and do not display the NOCSAE or SEI logo, as these organizations set standards for equipment but do not certify accessories. Including a disclaimer such as "This bag is not certified by NOCSAE or SEI; only your protective equipment can be certified" can help prevent misunderstandings.

For institutional buyers like schools, clubs, or leagues, provide a concise technical sheet outlining which types and sizes of NOCSAE-certified equipment the bag is designed to hold. This documentation should clarify that certification is conducted by third-party organizations like SEI – not the bag manufacturer – and emphasize that the bag is intended to help maintain certified gear in good condition. Institutions might also benefit from sample care instructions for coaches to share with athletes and a checklist template for athletic departments to ensure proper storage practices.

Clear labeling and documentation reinforce the bag’s role in preserving the integrity of NOCSAE-certified gear.

Conclusão

NOCSAE standards set the benchmark for protective gear performance, and custom bag designs must uphold that standard. By incorporating NOCSAE guidelines from the very beginning – such as determining which certified helmets, chest protectors, and shin guards will be stored, ensuring proper clearances and padding, and testing prototypes with actual equipment – manufacturers can help prevent damage that could compromise both certification and athlete safety.

But it’s not just about protection; design details matter too. Custom logos and branding should be placed thoughtfully to avoid interfering with protective compartments. Features like internal compliance checklists, clear labeling to distinguish certified gear from the bag itself, and practical care instructions – like keeping gear away from temperatures above 90°F and avoiding heavy stacking on helmets – can help U.S. buyers safeguard their equipment and meet league standards.

Partnering with a skilled custom manufacturer can simplify this process. SACOS DE JUNYUAN specializes in creating tailored compartments, padding, materials, and branding that align with protective needs while delivering the durability and quality U.S. buyers expect.

FAQs

How do NOCSAE standards impact the design of custom sports bags?

NOCSAE standards play a key role in shaping the design of custom sports bags by emphasizing safety and durability in sports equipment. Although these standards are mainly directed at protective gear, they indirectly guide manufacturers to use tough materials and smart construction techniques to keep the equipment inside sports bags safe.

This means custom sports bags often come with features like reinforced compartments, padded areas, and sturdy zippers. These design elements help ensure that helmets, pads, and other gear stay secure and in good condition. By following these guidelines, manufacturers not only help athletes protect their gear but also support them in staying compliant with safety requirements.

What should a custom sports bag include to protect NOCSAE-certified equipment?

When choosing a sports bag to safeguard NOCSAE-certified equipment, durability e practical design should be at the top of your list. Opt for bags with impact-resistant padding to cushion your gear against bumps, secure compartments to keep everything in place, and ventilated materials to reduce moisture and odor. Features like reinforced zippers e adjustable compartments also add an extra layer of protection and help keep your equipment neatly organized while on the move.

Why is it important to follow safety standards when adding custom branding to sports bags?

Ensuring that custom branding on sports bags aligns with safety standards is important for several reasons. Designs that fail to meet these standards can weaken the bag’s durability, break regulations, or even put users at risk. Beyond that, branding that is inappropriate or misleading can open the door to legal troubles or liability concerns for manufacturers and businesses.

To steer clear of these issues, companies like SACOS DE JUNYUAN focus on following proper branding practices. By sticking to established guidelines, they guarantee that custom sports bags not only meet safety standards but also deliver the quality customers expect – offering reassurance to both buyers and users.

Telemóvel/What's App/Wechat

Telemóvel/What's App/Wechat E-Mail

E-Mail ADD

ADD