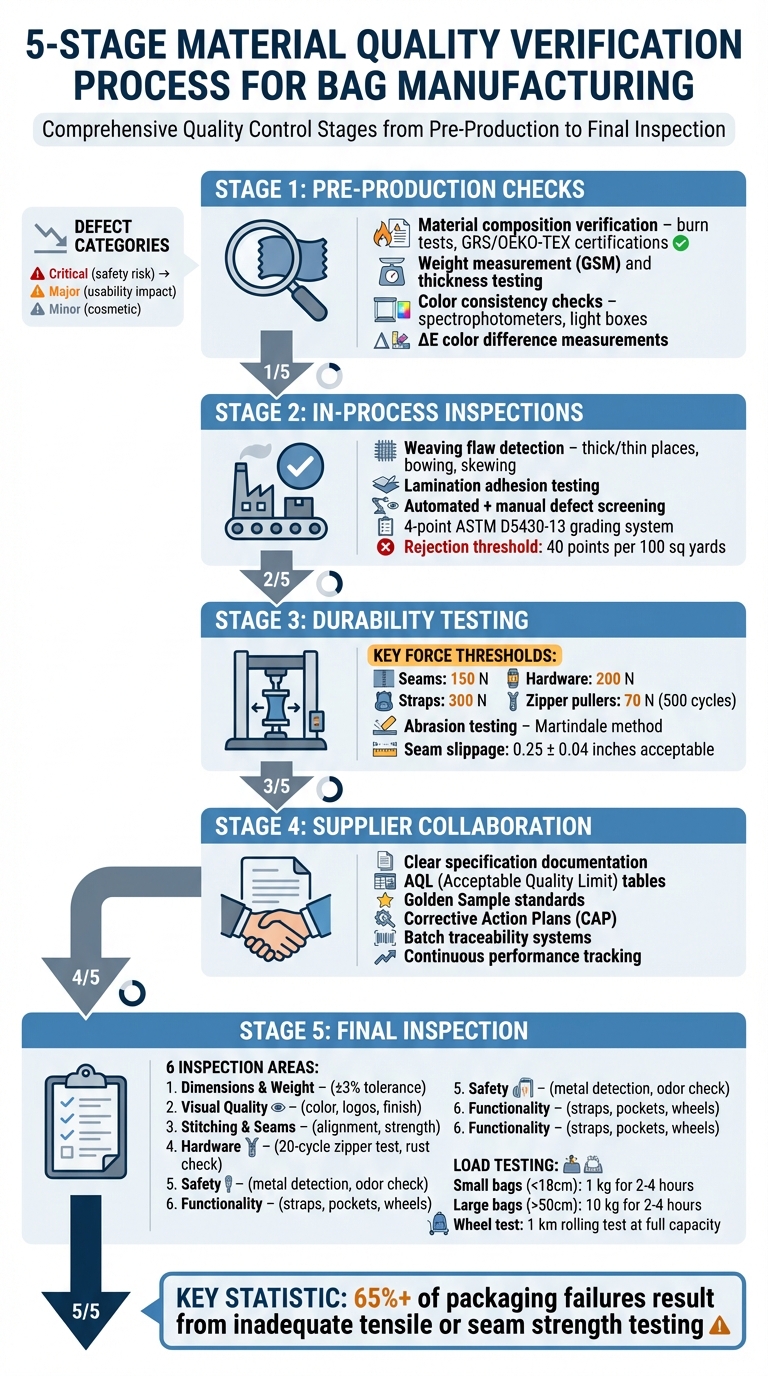

Material quality can make or break a bag’s durability and performance. Here’s how manufacturers ensure top-notch materials:

- Pre-Production Checks:

- Confirm material composition using burn tests and certifications like GRS or OEKO-TEX.

- Measure weight (GSM) and thickness for consistency.

- Inspect color and finish using tools like spectrophotometers and light boxes.

- In-Process Inspections:

- Check for weaving flaws, lamination issues, and adhesion strength.

- Use automated systems and manual inspections to spot defects early.

- Grade defects based on ASTM standards to decide pass or fail.

- Durability Testing:

- Conduct tensile strength tests for seams, straps, and hardware.

- Perform abrasion and rub tests to simulate wear and tear.

- Test seam and stitch integrity to ensure long-term performance.

- Supplier Collaboration:

- Document specifications clearly, including benchmarks for strength and durability.

- Use AQL tables to define acceptable defect levels.

- Implement corrective action plans for any inconsistencies.

- Final Inspection:

- Verify dimensions, stitching, hardware, and functionality.

- Perform load tests, adhesion checks, and rolling tests for specific components.

Key Takeaway: Rigorous testing and inspections at every stage – pre-production, in-process, and post-production – ensure bags meet durability and quality standards while safeguarding a brand’s reputation.

5-Stage Material Quality Verification Process for Bag Manufacturing

Packaging Bags Durability Test: Quality & Protection

sbb-itb-1e6451b

Material Quality Checks Before Production

Before production begins, materials are subjected to rigorous checks to help eliminate defects later in the process. These pre-production evaluations are critical for ensuring consistent performance throughout manufacturing. As Zenda Textile explains:

Fabric quality cannot be fully assessed by eye or touch. What feels soft may not be strong. What looks thick may not be water-resistant.

This is why structured testing is indispensable. These early steps lay the groundwork for reliable in-process inspections.

Verifying Material Composition

The first step is confirming the material’s composition. Substituting cheaper materials is a frequent issue, as Megan Young from InTouch Quality notes:

The substitution of original quality materials for cheaper, lower quality ones is an unfortunate but very recurring problem in products made in China and elsewhere.

A burn test can help identify authenticity – genuine leather, for example, resists burning and doesn’t emit a plastic smell. For fabrics, chemical analysis like burn or solubility tests can verify fiber blends. Lab tests further confirm material specifications. Certifications such as the Global Recycled Standard (GRS) or OEKO-TEX Standard 100 provide additional assurance, verifying recycled content and ensuring the absence of harmful substances.

Measuring Weight and Thickness

Fabric weight, often measured in grams per square meter (GSM), indicates the material’s density. To determine GSM, cut a 10×10 cm (approximately 3.9×3.9 in) sample, weigh it, and multiply the result by 100. Tools like a GSM cutter and precision balance help ensure accurate measurements.

Thickness is another key metric. Following ASTM D1777 standards, thickness is measured under specific pressure conditions, as the results can vary depending on the applied pressure. Always document the exact pressure used during testing. Conducting comparative tests with your supplier ensures consistent results before moving to large-scale production.

Once physical properties are confirmed, focus shifts to aesthetic consistency to maintain overall quality.

Checking Color and Finish Consistency

Color inconsistencies can derail an entire production batch. Begin by visually inspecting materials in a light box under different light sources, such as D65 and TL84, to detect metamerism – where colors appear different under varying lighting. Use a spectrophotometer to measure the color difference (ΔE) between samples and the standard, taking multiple readings across the fabric roll to account for variations. Set clear ΔE limits based on brand standards to make pass/fail decisions.

For precise color matching, rely on Pantone standards for both primary fabrics and accessories like zippers and buttons to avoid any miscommunication. Additionally, perform colorfastness tests, such as rubbing tests with a crockmeter and a white cloth, to ensure the material won’t stain clothing. These tests are graded on a scale from 1 to 5, with Grade 5 indicating excellent resistance and Grade 1 signaling poor quality.

Material Inspection During Manufacturing

When production kicks off, quality control becomes a real-time effort. Catching defects during manufacturing instead of waiting until the end saves both labor and materials. As Zoey Lee, Sales Director at Osgoodway, explains:

By catching any problems at this early stage, factories can make adjustments before the mass production process begins.

Inspections are strategically timed at key stages like cutting, stitching, and attaching zippers or hardware. This step-by-step approach ensures any issues are addressed before they become part of the final product, creating a seamless link between pre-production checks and final quality assurance.

Checking Weaving and Lamination

Weaving problems often show up as irregularities in the fabric. Issues like "thick places" (clusters of thick yarns) or "thin places" (gaps from loosely spaced yarns) usually point to tension or gear problems. Other signs, such as "bowing" (arcing filling yarns) or "skewing" (angular misalignment of yarns), suggest uneven tension during finishing. Visual flaws like "barre" (striped patterns across the fabric) typically result from inconsistencies in the yarn’s physical or dye properties.

For laminated materials, such as BOPP bags, adhesion testing is a must. Peel tests ensure that the layers stay intact during use. Coating thickness is another critical factor – uneven coatings can lead to weak spots that tear easily or allow moisture to seep through. Backlit or light table inspections help identify tiny defects like pinholes, leaks, or weaving flaws that might go unnoticed under regular lighting.

Screening for Defects During Production

Building on earlier quality checks, inspections during production combine advanced technology with human expertise to ensure consistent quality. Many modern facilities rely on automated systems like high-resolution cameras paired with image processing software. These systems can scan fabric for surface defects such as holes, tears, or color inconsistencies at speeds of up to 2,000 meters per minute. However, even the best machines have their limits. Skilled workers still play a crucial role, performing hands-on checks for stitching, thread count, and structural integrity to catch what automation might miss.

The 4-point ASTM D5430-13 system provides a standardized way to grade defects. Points are assigned based on the size of the flaw: defects up to 3 inches (75 mm) earn 1 point, while those over 9 inches (230 mm) get 4 points. If a fabric roll exceeds the allowable point limit – usually set at 40 points per 100 square yards – it’s rejected to avoid wasting resources on defective material.

Real-time tracking through quality control software monitors metrics like stitching speed and machine performance, flagging deviations immediately. When defects arise, manufacturers conduct root cause analyses to pinpoint whether the problem stems from equipment issues, worker training gaps, or subpar raw materials. This approach tackles the root of the problem rather than just the symptoms, driving long-term improvements in consistency.

These in-process checks are a key part of maintaining supplier quality and ensuring every bag meets the high standards expected at JUNYUAN BAGS.

Testing Methods for Material Durability

After initial inspections, lab tests are used to confirm how materials perform under stress. Manufacturers follow international standards like ISO 13934-1 and ASTM D5034 to ensure reliability and consistency in results. These durability tests build on earlier inspections, focusing on how materials hold up over time.

Tensile Strength and Pull Tests

Tensile tests are designed to measure the maximum force a material can handle before breaking. Specialized machines apply controlled force at a rate of 100 mm/min. Key components like seams, straps, hardware, and zipper pullers must meet specific force thresholds to pass testing. For example:

- Seams: 150 N

- Straps: 300 N

- Hardware: 200 N

- Zipper pullers: 70 N

Additionally, zipper pullers are tested to ensure they remain functional after 500 open-close cycles.

"Rigorous testing uncovers potential design or manufacturing defects early." – Mr. Li, Quality Control Expert, Sunteam

Regular tensile and tear strength tests, such as ASTM D2261, help identify any fluctuations in material quality.

Abrasion and Rub Tests

Abrasion tests replicate the wear and tear caused by friction over time. The Martindale Abrasion Tester is commonly used for fabrics like knits, wovens, and nonwovens. It uses a circular rubbing motion to measure how many cycles a material can endure before significant wear appears. Factors like the type of abradant, fabric tension, and applied pressure all influence the results.

Testing is performed under both dry and wet conditions. Wet tests are particularly useful for understanding how moisture impacts durability, as water can wash away debris that might otherwise skew results. To get a full picture of material performance, manufacturers also evaluate fabric rupture, mass loss, thickness loss, and breaking strength loss. To maintain accurate results, abradants must be regularly calibrated or replaced.

Seam and Stitch Integrity Testing

Seams are often weak points in bag construction, making their testing critical. ASTM D1683 evaluates how much force a seam can handle before breaking. It also distinguishes between repairable failures (where stitching fails) and non-repairable ones (where yarns slip or fabric tears). Seam durability depends on several factors, including thread size, stitch type, seam type, and stitch density. Testing measures the force at which yarns start to displace, with an acceptable threshold of 0.25 ± 0.04 inches (6 ± 1 mm).

Drop tests are another way to simulate real-world impacts. These thorough tests reflect the commitment to producing bags that meet strict quality and durability standards. At JUNYUAN BAGS, every production run undergoes batch-wise testing to catch quality variations caused by material fatigue or process changes before products reach customers.

Working with Suppliers for Quality Assurance

To avoid material inconsistencies, it’s essential to have clear, well-documented standards and a system for consistently tracking performance. Early detection of issues and mutual accountability are key to maintaining quality.

Agreeing on Specifications and Documentation

Before production begins, document every material detail. This includes specifications like fabric denier, filament count, GSM, weave type, and coating type. Be specific about dimensions, Pantone color codes, and logo placement.

Set measurable benchmarks for performance, such as tensile strength, tear resistance, abrasion durability, and colorfastness. For example, shoulder straps might need to withstand at least 300N of force, seams should hold between 150N and 200N, and zippers should function properly after 500 cycles. Always request a "Golden Sample" to serve as the definitive quality standard.

Documentation should include technical data sheets, design sketches, lab test reports, and compliance certificates for standards like REACH, OEKO-TEX Standard 100, and the Global Recycled Standard (GRS). Use AQL (Acceptable Quality Limit) tables to define acceptable defect levels for minor, major, and critical issues. For size and weight, apply a standard tolerance of +/- 3%.

Reporting and Resolving Defects

Introduce quality checkpoints at every stage of production. Conduct DUPRO (During Production) inspections to identify workmanship defects or design deviations early.

When defects are found, implement a Corrective Action Plan (CAP) to address the root cause. Use digital tools to document observations, include photos, and provide clear recommendations for suppliers. Root-cause analysis should determine whether the issue stems from machine malfunctions, insufficient training, or faulty material batches.

"Corrective actions are where quality control (QC) moves from inspection to improvement." – Qarma Quality & Compliance

Ensure batch traceability by labeling products with codes that link back to raw material batches, manufacturing data, and test results. After resolving defects, maintain continuous monitoring to prevent recurrence and ensure consistent quality.

Tracking Performance Metrics and Conducting Audits

Effective supplier management combines corrective actions with ongoing performance tracking. Conduct audits at pre-production, in-process, and post-production stages to confirm adherence to standards. Use measurable metrics like GSM, denier, weave density, tensile strength, and colorfastness to track material quality. Third-party inspections can provide unbiased reviews and confirm compliance with standards like ISO 9001.

Modern manufacturing facilities increasingly rely on automated techniques like laser cutting and automated stitching to reduce human error. These advanced systems support multi-stage quality control with transparent reporting and rigorous compliance checks.

JUNYUAN BAGS employs a similar strategy, performing batch-wise testing for every production run to catch variations caused by material fatigue or process shifts.

Establish a feedback loop where inspection results and customer reports are shared with suppliers. This ongoing communication turns quality control into a continuous improvement process, strengthening the supply chain over time.

Final Quality Inspection Checklist

This checklist serves as the ultimate pass/fail guide, ensuring that all prior evaluations and in-process checks culminate in a thorough and definitive inspection. Conducting this final review ensures every component meets documented standards, catching any issues that could compromise the entire production batch. It provides a structured framework to confirm compliance with established requirements.

Inspection Areas and Key Checkpoints

The final inspection focuses on six primary areas:

- Dimensions & Weight: Confirm that all measurements – length, width, height, and weight – fall within ±3% of the approved sample.

- Visual Quality: Inspect for consistent color shading, proper logo placement, and ensure the finish is free of stains, tears, or other defects.

- Stitching & Seams: Check that stitches are aligned, with no loose threads or needle holes. Perform a seam-pulling test to assess stitching strength.

- Hardware: Test zippers for smooth operation after 20 cycles, check buckles for secure fastening, and inspect metal components for rust or corrosion.

- Safety: Ensure no metal fragments are detected, and verify there are no irritative odors or mildew.

- 機能性: Test moving parts like adjustable straps, pocket closures, and wheels to confirm smooth operation without snagging.

| Inspection Area | Key Checkpoints | Pass/Fail Criteria |

|---|---|---|

| Dimensions & Weight | Length, width, height, total weight | Within ±3% of the standard sample |

| Visual Quality | Color shading, logo placement, material finish | No visible defects |

| Stitching & Seams | Stitch density, thread trimming, seam strength | No loose threads or needle holes |

| Hardware | Zipper smoothness, buckle tension, metal finish | No jamming; operates after 20 cycles; no rust |

| 安全性 | Metal detection, odor and mildew check | Zero metal fragments; no irritative odors |

| Functionality | Operation of straps, pockets, wheels, etc. | All moving parts function smoothly |

Acceptance Criteria and Recommendations

Establishing clear acceptance criteria simplifies the inspection process and ensures consistency. Examples include:

- Load-Bearing Components: Handles and straps must hold specific weights – 1 kg (≈2.2 lbs) for smaller bags (under 18 cm or 7 inches) and up to 10 kg (≈22 lbs) for larger bags (over 50 cm or 20 inches) – for 2 to 4 hours without damage.

- Small Accessories: Buttons and zipper pullers should withstand a force of 50–90 N for 10 seconds.

- Adhesion Testing: Perform the 3M tape test using 3M600 or 6110 tape to ensure logo and label adhesion. Markings should not peel when the tape is removed at a 45-degree angle.

- Wheel Durability: For bags with wheels, conduct a "walking test" by loading the bag to capacity and rolling it continuously for 1 km (≈0.62 miles) to evaluate wheel and handle durability.

Defects are categorized as follows:

- Critical: These defects pose safety risks or cause complete functional failure, leading to immediate batch rejection.

- Major: These issues impact usability significantly but may allow for rework if the root cause is addressed.

- Minor: These are cosmetic flaws that don’t affect functionality but should still be monitored under Acceptable Quality Limit (AQL) guidelines.

"You need to specify your requirements and steps for inspection to get a truly accurate report of your order’s quality." – Testcoo

JUNYUAN BAGS adheres to these rigorous checkpoints to ensure consistent quality.

Conclusion

Ensuring material quality is an ongoing process – starting from the initial selection and continuing through to final delivery. Standardized tests are a must, especially since more than 65% of packaging failures stem from inadequate tensile or seam strength testing. Catching defects early, whether during pre-production or in-process monitoring, can save you from the hefty costs tied to mass-production errors. It also helps safeguard your brand’s reputation from issues like weak stitching or color mismatches that could end up in the hands of consumers. This level of vigilance naturally ties into building strong supplier relationships.

Long-term partnerships with reliable suppliers are key. By requesting detailed lab reports, compliance certifications, and setting clear specifications upfront, you remove uncertainty and guarantee consistent material quality across every batch.

A combination of rigorous testing protocols and proactive supplier management lays the foundation for producing high-quality bags that meet both functional and aesthetic demands. Multi-stage inspections, which blend automated and manual checks alongside random sampling, ensure every product aligns with expectations.

FAQs

What are the best ways to check material quality during bag manufacturing?

To create durable and reliable bags, it’s essential to prioritize material quality. This involves focusing on three critical testing areas:

- Strength and durability: Check the tensile strength of stitching, zippers, and seams to ensure they can handle regular use and stress without failing.

- Functionality: Test hardware, straps, and closures to confirm they operate smoothly and consistently.

- Resistance to external factors: Assess how well the materials hold up against water, moisture, and other environmental challenges to ensure longevity.

Regular testing combined with clear communication with your supplier helps ensure the materials align with your quality expectations and manufacturing goals.

How do manufacturers maintain consistent color and finish in bag production?

Manufacturers ensure that the color and finish of their products remain consistent by applying rigorous quality control processes throughout production. This begins with carefully evaluating colors during raw material selection and continues through formulation and production stages to maintain accuracy and uniformity.

To verify the durability and stability of finishes, manufacturers rely on standardized testing methods, such as those outlined by ASTM. These tests assess factors like water resistance and coating durability. Additionally, regular inspections – both visual and laboratory-based – are conducted to spot and address any inconsistencies before the bags reach their final stage. This meticulous approach guarantees that the finished products meet high standards and align with customer expectations.

Why is working closely with suppliers important for ensuring material quality in bag manufacturing?

Collaborating with suppliers plays a key role in ensuring top-notch material quality. Open communication, transparency, and trust are the backbone of this relationship, helping to guarantee that raw materials meet your specific standards. This reduces the chances of using fabrics or components that could compromise the durability or performance of your bags.

Strong supplier relationships also allow for regular quality checks, access to detailed material specifications, and the ability to address issues early in production. A reliable supply chain built on trust and clear communication can make a significant difference in the success of your bag manufacturing efforts.

モバイル/What's App/Wechat

モバイル/What's App/Wechat Eメール

Eメール 追加

追加