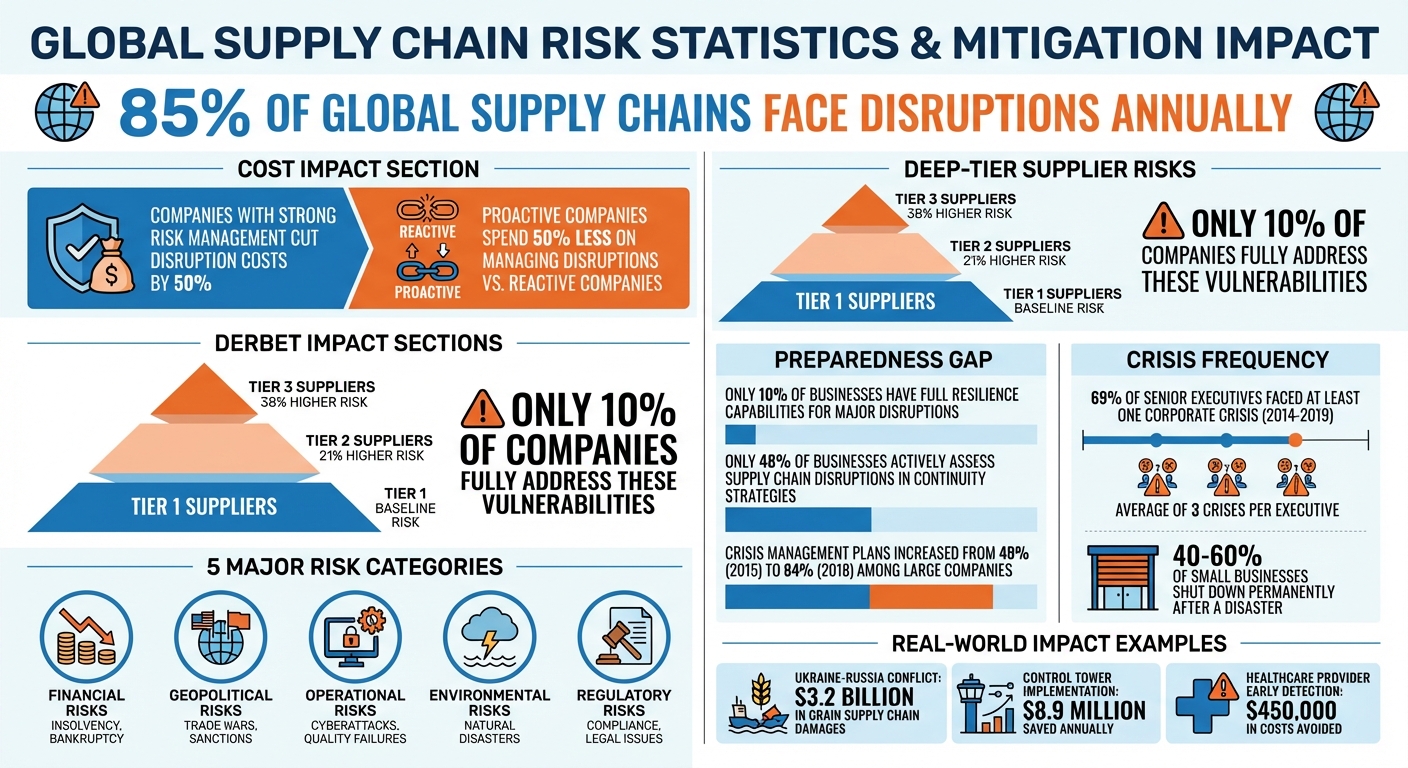

85% of global supply chains face disruptions annually. From natural disasters to cyberattacks, these risks can halt operations, drain revenue, and damage customer trust. Companies lose millions, not just in delayed shipments but also in emergency sourcing, penalties, and legal issues. Yet, businesses with strong risk management cut disruption costs by 50%.

Here’s what you need to know:

- Hidden Risks in Deep-Tier Suppliers: Risks increase by 21% at Tier 2 and 38% at Tier 3 suppliers. However, only 10% of companies fully address these vulnerabilities.

- Key Risk Categories: Financial instability, geopolitical tensions, cyberattacks, natural disasters, and regulatory issues are common threats.

- Effective Solutions:

- Map all supply chain layers (Tier 1, 2, 3).

- Diversify suppliers geographically and operationally.

- Use AI tools for real-time risk monitoring.

- Build strong supplier relationships and contingency plans.

Companies that act now can strengthen supply chains, reduce costs, and protect their reputation. The full article explains practical steps to assess and manage risks effectively.

Global Supply Chain Risk Statistics and Mitigation Impact

Types of Risks in International Supplier Networks

Main Risk Categories

International supplier networks face five major categories of risks that can disrupt operations with little to no warning. Financial risks – like supplier insolvency, bankruptcy, or economic instability – can halt production unexpectedly. Geopolitical risks, such as trade wars, sanctions, or regional conflicts (think U.S.-China competition or Russia-NATO tensions), often impose operational limits and force tough decisions. Then there are operational risks, which include cyberattacks, quality failures, and labor disputes that can lead to production delays or costly product recalls.

Environmental and climate risks are another significant concern. Hurricanes, floods, and other natural disasters can damage manufacturing plants or block critical transportation routes. Finally, regulatory and legal risks revolve around compliance with human rights laws, carbon taxes, and trade regulations. Falling short in these areas can result in fines and tarnished reputations. McKinsey highlights this complexity:

Risk management is not merely about setting up processes and governance models, but also entails shifts in culture and mind-sets.

Adding to the complexity are risks tied to deep-tier suppliers, which are often overlooked. Many companies focus only on their direct suppliers, leaving themselves vulnerable to disruptions originating further down the supply chain.

These risks aren’t hypothetical – they’re playing out in real-world scenarios with significant consequences.

Examples of Supply Chain Disruptions

The ongoing Ukraine-Russia conflict is a clear example of geopolitical risk turning into financial losses. Disruptions to the grain supply chain alone have resulted in an estimated $3.2 billion in damages. Sanctions and trade restrictions don’t just inflate costs; they can force businesses to completely overhaul their supply chains.

Natural disasters also wreak havoc on supply networks. For instance, hurricane season in South Florida can shut down key logistics hubs, while an unexpected volcanic eruption in a manufacturing region can erase months of production capacity.

Cyberattacks represent a growing operational threat, targeting supplier networks to steal proprietary data or introduce counterfeit components into the production process. Quality defects can be just as damaging – a single faulty part from a lower-tier supplier can lead to widespread recalls and a loss of customer trust.

These challenges are not rare occurrences. Yet, despite their frequency, only 10% of companies have built the full range of resilience strategies needed to handle such disruptions.

How to Build a Resilient Global Supplier Network

Supplier Mapping and Risk Assessment

To build a resilient supplier network, the first step is understanding every link in your supply chain. While many companies focus on their direct (Tier 1) suppliers, the reality is that risks often lie deeper within Tier 2 and Tier 3 suppliers. These hidden layers can pose significant challenges.

Start by mapping your entire value chain. This means identifying every component – from manufacturing facilities and warehouses to transportation routes and sub-tier suppliers. Use your bills of materials to trace critical products back to their origins. Once mapped, create a scoring system to evaluate risks based on impact, likelihood, and readiness.

Leverage digital tools to monitor real-time data like news alerts, financial reports, and weather updates. This proactive approach can reduce disruption costs by as much as 50%. Establish a cross-functional risk board with members from procurement, legal, finance, and operations. This team should regularly review risks and develop mitigation plans . As BCG highlights:

The philosophy of risk management must transition from reactive firefighting to proactive management and reduction of risk exposure.

Track metrics such as PPM defect rates, which can indicate financial instability among suppliers. Update supplier portals to require Tier 1 vendors to provide data on their operations, volume commitments, and reliance on sub-tier suppliers. This structured data gathering turns vague supplier relationships into actionable insights. With this information, you can develop strategies to diversify your supplier base and reduce vulnerabilities.

Diversifying Your Supplier Base

Once risks have been assessed, the next step is diversification. Relying on a single supplier for critical components creates unnecessary vulnerabilities. Multi-sourcing – working with multiple suppliers for the same part – provides a safety net if one supplier is impacted by regional disruptions, natural disasters, or financial troubles. For example, in 2019, U.S. auto-part imports from China dropped by 17%, while imports from Turkey and Southeast Asia increased by 10% and 24%, respectively, as companies sought alternatives.

Nearshoring is another effective strategy. By sourcing suppliers closer to your target market, you can reduce lead times and shipping risks. This approach also simplifies logistics and avoids some of the challenges associated with global tariffs. When evaluating suppliers, look beyond the per-unit cost and consider the Total Cost of Ownership (TCO), which includes freight, tariffs, and delivery times. As NIST aptly puts it:

Cheaper is where innovation and value go to die. Competing on cost per unit makes you replaceable. It is not sustainable.

Here’s a quick comparison of key diversification strategies:

| Strategy | Primary Benefit | Key Trade-off |

|---|---|---|

| Multi-sourcing | Reduces reliance on one supplier; increases leverage | Higher administrative costs; potential loss of volume discounts |

| Nearshoring | Shortens lead times; lowers transport risks | Often involves higher labor or material costs |

| Domestic Sourcing | Stronger IP protection; easier communication | May face capacity limitations in specialized areas |

To strengthen your network, consider tiered redundancy by maintaining backup suppliers for high-volume parts and selective redundancy for lower-priority components. Build inventory and capacity buffers, especially during high-risk periods like hurricane seasons or product launches. Standardizing components across product lines can also add flexibility if a supplier issue arises.

One crucial point to keep in mind: adding more suppliers increases your cybersecurity risks. Be sure to enforce strict compliance and data protection standards for all third-party vendors. Regular stress tests on your supplier network can help uncover vulnerabilities that might otherwise go unnoticed deep within your supply chain.

Tools and Techniques for Managing Supplier Risk

Supplier Risk Assessment Tools

After mapping out and diversifying your supplier network, the next step is staying on top of potential risks. The right tools can help you spot issues before they escalate.

Supplier scorecards are a great way to track performance across areas like quality, delivery, compliance, service, and finances. To get the most out of them, focus on 2–3 metrics that align with your current priorities. For instance, if you’re navigating financial challenges, you might emphasize cost performance and invoice accuracy. On the other hand, during a product launch, innovation and lead times might take center stage. As Suman Sarkar, Partner at 3S Consulting, puts it:

"Scorecards are a good way to hold suppliers accountable and track their progress toward achieving business results."

Scorecards not only track performance but also motivate suppliers to improve. Knowing they’re being monitored often leads to better results – a phenomenon known as the Hawthorne Effect. High-performing suppliers can even be rewarded with opportunities to bid on new projects or receive priority for contract renewals.

AI-powered tools take monitoring to another level. These platforms analyze data in real time – from news updates and financial reports to social media and weather patterns – to predict supplier risks before they become critical. For example, a global brewery used predictive analytics to monitor raw material prices. When the system flagged a potential shortage of molded glass vials, the company acted swiftly, stockpiling supplies and locking in long-term contracts. This proactive approach helped them avoid both price hikes and supply chain disruptions.

Another useful tool is a risk register, which scores risks based on their likelihood, impact, and your organization’s readiness to respond. Combine this with sub-tier transparency tools that use AI and optical character recognition (OCR) to scan contracts and audit documents. These tools map out Tier 2 and Tier 3 suppliers, exposing hidden vulnerabilities deep in your supply chain. Why does this matter? The risk of disruption is 21% higher at Tier 2 and 38% higher at Tier 3 compared to Tier 1 suppliers.

Control towers provide real-time dashboards and simulations, such as digital twins, to model supply chain scenarios. One example: a consumer products company used a GIS-based control tower to predict weather-related disruptions along transportation routes. This system identified risks 10 days in advance, saving the company an estimated $8.9 million annually in force majeure losses. Similarly, a healthcare provider detected an impending phlebotomy supply shortage three weeks before it became public knowledge, allowing them to secure 120 days of safety stock and avoid $450,000 in costs.

Tracking leading indicators like "right first time" rates, deviation cycle times, and parts-per-million defect rates can also provide early warnings. For instance, rising defect rates may hint at financial instability. Companies that address supply chain risks proactively spend 50% less on managing disruptions compared to those that react after the fact.

| Tool Type | Primary Function | Key Benefit |

|---|---|---|

| Supplier Scorecards | Monitor performance across quality, delivery, and finance | Identifies underperformers and encourages improvements |

| AI Predictive Analytics | Analyze real-time data from various sources | Flags potential risks like shortages or insolvencies early |

| Risk Registers | Catalog and score risks by impact and likelihood | Creates a structured framework for tracking mitigation efforts |

| Sub-tier Transparency Tools | Map Tier 2 and Tier 3 suppliers | Exposes hidden vulnerabilities in deeper supply chain layers |

| Control Towers | Real-time dashboards and scenario simulations | Predicts disruptions and optimizes logistics in real time |

While these tools are invaluable, they work best when paired with strong supplier relationships.

Supplier Collaboration and Development Programs

Advanced tools are excellent for identifying risks, but they can’t replace the value of strong supplier relationships. Building trust and fostering open communication with suppliers lays the groundwork for effective risk management. As the National Institute of Standards and Technology (NIST) emphasizes, "relationship capital" is key during disruptions.

Start with joint risk planning. Research from BCG highlights the importance of moving away from reactive "firefighting" and toward proactive strategies. Hosting structured "risk conventions" with suppliers can help both parties align on risk assessments and mitigation plans. These meetings ensure everyone understands each other’s vulnerabilities and capabilities, paving the way for smoother crisis management.

Supplier development programs take collaboration even further. These initiatives aim to optimize supplier operations, improve worker training, and ensure quality and compliance standards are met. For instance, an automotive company analyzed over 6,000 supplier-commodity combinations to identify high-risk areas. They then created a risk mitigation playbook and worked closely with critical suppliers to shift from reactive to proactive management.

Another way to enhance collaboration is by aligning internal teams and suppliers on risk priorities. Embedding risk specialists into R&D and production teams can ensure that suppliers grow alongside your business. Additionally, updating supplier portals to require Tier 1 vendors to share data about their upstream suppliers – such as countries of operation and capacity constraints – can improve visibility. This is crucial, as 85% of global supply chains experience at least one disruption annually.

Scorecards can also serve as conversation starters for development. For example, if a supplier struggles with on-time delivery, work together to identify and address bottlenecks. This might involve improving production planning or sourcing raw materials more efficiently. As Gary Gustafson, President of G-Force Consulting, explains:

"Supplier scorecards provide an objective, data-driven analysis of supplier performance, which helps remove mistakes or personal biases from the process of managing the supply chain."

Lastly, formalizing dispute resolution processes is essential. Even the strongest relationships can face disagreements, so clear communication protocols and fair resolution mechanisms are vital. Remember, your business is only as strong as the suppliers it relies on. Investing in their success is an investment in your own resilience.

Supply Chain Risk Management: A Most Delicate Balancing Act

sbb-itb-1e6451b

Creating Contingency Plans for Supply Chain Disruptions

No matter how advanced your monitoring systems are or how strong your supplier relationships might be, disruptions are bound to happen. The difference between companies that recover quickly and those that struggle often comes down to preparation. In fact, organizations with crisis response plans perform nearly twice as well during disruptions. Yet, surprisingly, only 48% of businesses actively assess and address supply chain disruptions as part of their continuity strategies.

The numbers paint a sobering picture: between 2014 and 2019, 69% of senior executives faced at least one corporate crisis, with an average of three crises per executive. For small businesses, the risks are even higher – 40% to 60% shut down permanently after a disaster. Contingency planning is essential, working hand in hand with risk mapping and diversification to keep supply chains steady in turbulent times.

Alternative Sourcing Strategies

A strong contingency plan begins with identifying critical components in your supply chain that are most vulnerable to disruptions. Once these are mapped out, you can craft alternative sourcing strategies tailored to their importance.

Multi-sourcing is a key strategy. This involves qualifying backup suppliers or manufacturers in different regions to ensure redundancy. For example, during the US–China trade war, Samsung shifted smartphone production from China to India and Vietnam, while LG Electronics relocated refrigerator production for the U.S. market to South Korea. Similarly, Mazda responded to pandemic-related lockdowns by moving some automotive component manufacturing from China to Mexico.

Geographic diversification is crucial, but it’s only part of the equation. Inventory strategies also play a role. The traditional Just-in-Time (JIT) model has evolved into a hybrid approach that includes strategic safety buffers. To calculate inventory needs, use this formula: (Daily Usage × Lead Time) + Safety Stock. This method ensures you have enough stock for critical items without overloading your budget with unnecessary inventory.

Another option to consider is nearshoring or reshoring for essential supplies. For example, Taiwan Semiconductor Manufacturing (TSMC) committed $12 billion in 2020 to build a plant in Arizona, reducing dependence on Asian suppliers and ensuring secure access for U.S. customers. While domestic sourcing might seem more expensive upfront, evaluating the Total Cost of Ownership (TCO) – factoring in freight, tariffs, lead times, and potential disruption costs – often shows local suppliers to be more cost-effective in the long run.

Flexible contracts are another tool in your contingency arsenal. Negotiate agreements that include surge capacity, alternative supply routes, and clear protocols for delays. For smaller manufacturers, organizations like the MEP National Network can help identify domestic suppliers to replace overseas sources, strengthening resilience through local partnerships.

Once you’ve secured diversified sources, it’s critical to establish clear protocols for activating these alternatives during a disruption.

Crisis Response Protocols

Having backup suppliers isn’t enough – you need a clear plan for how and when to use them. Well-defined protocols ensure your team can act swiftly and decisively when disruptions occur. As Deborah Hileman, President and CEO of the Institute for Crisis Management, puts it:

"A good crisis plan possesses a variety of elements that prepare crisis team members to effectively perform their duties when a crisis occurs."

Start by setting activation triggers with specific thresholds that signal when to engage backup suppliers and notify customers.

Next, establish a crisis-specific chain of command to clarify who makes decisions and how information flows. For decentralized organizations, designate a primary and backup command center equipped with essential communication tools and power capabilities.

Adopt an all-hazard approach when creating your response plans. Instead of crafting playbooks for every potential crisis, design modular plans that can adapt to a variety of scenarios. Regina Phelps, Founder of Emergency Management & Safety Solutions, explains:

"The best plans use an all-hazard approach, meaning you don’t write plans with a specific crisis in mind, but rather with all potential hazards in mind."

These modular plans might include steps like shutting down production lines, activating alternative transportation routes, notifying regulatory agencies, or communicating with stakeholders. Assign specific roles to individuals or teams so everyone knows their responsibilities when a crisis hits.

Prepare pre-drafted holding statements for internal teams, customers, and external stakeholders to ensure swift and consistent communication. Regularly conduct drills – ideally quarterly – to test your team’s readiness and coordination.

Finally, treat your contingency plan as a living document. Review and update it annually or whenever there are major changes to your processes, suppliers, or facilities. After any disruption, conduct a post-crisis analysis to identify what worked and what didn’t, and incorporate those lessons into your updated plan. It’s worth noting that between 2015 and 2018, the percentage of large companies with crisis management plans rose from 49% to 84% – a clear sign of the growing importance of preparation.

Case Study: JUNYUAN BAGS and Custom Bag Supply Chains

To illustrate how risk management principles come to life, let’s dive into how JUNYUAN BAGS navigates the complexities of the custom bag industry.

The custom bag manufacturing sector presents unique challenges. Unlike mass production, creating customizable products demands adaptable production systems, strict quality control, and a responsive supplier network capable of adjusting to shifting client needs. JUNYUAN BAGS has built a global supplier network tailored to these demands, employing practical strategies to tackle common risks in international manufacturing.

Certifications and Standards as a Safety Net

JUNYUAN BAGS uses international certifications to maintain consistent quality across its supply chain. Suppliers are required to hold certifications such as BSCI, ISO9001, CE, and RoHS. The BSCI audit process is particularly crucial, ensuring that suppliers meet standards for factory licensing, trade and fire safety, environmental compliance, and quality control. Certifications like ISO9001 go beyond compliance – they provide a structured system for tracking and improving supplier performance. By monitoring quality metrics, JUNYUAN BAGS identifies trends and addresses potential issues before they escalate. This certification-driven approach forms a key part of the company’s strategy to ensure a reliable and resilient supply chain.

Focusing on Long-Term Supplier Relationships

Rather than relying on one-off transactions, JUNYUAN BAGS invests in long-term relationships with its suppliers. This "relationship capital" fosters trust and collaboration, creating mutual value. These strong partnerships prove invaluable during disruptions – whether it’s a material shortage or a sudden need for rush orders, suppliers are more likely to prioritize JUNYUAN BAGS’ needs. Additionally, the company actively works on supplier development, helping partners improve quality, compliance, and sustainability. Instead of simply switching suppliers when problems arise, JUNYUAN BAGS builds partnerships designed to last. As highlighted in the BCI Horizon Scan Report 2025:

A few years ago, you might have said, ‘Yes, we have a plan,’ and that would have been enough. Now companies want to see your plan, evidence of testing, and audits. It’s no longer just trust; we need guarantees.

Flexibility: The Backbone of Custom Manufacturing

Operational flexibility is another cornerstone of JUNYUAN BAGS’ success. Custom bag production requires agility, and the company achieves this by maintaining a geographically diverse supplier network. This reduces risks from localized disruptions like natural disasters or political instability. On the inventory side, JUNYUAN BAGS strikes a balance between lean operations and maintaining safety stock for critical materials and high-demand items. This "just-in-case" approach ensures that production can continue even during supply chain hiccups.

Digital tools also play a role in maintaining flexibility. By using real-time procurement platforms, JUNYUAN BAGS tracks supplier performance and identifies potential issues early, allowing for proactive adjustments. Given that third-party failures account for 9.3% of supply chain disruptions, this kind of monitoring is essential. The company further enhances its adaptability by offering both OEM and ODM manufacturing services, enabling it to meet diverse customer needs and respond to changing market conditions.

Conclusion

Managing risks in a global supplier network isn’t something you can check off a to-do list – it’s an ongoing effort that demands forward-thinking, close collaboration with suppliers, and constant vigilance. Here’s a compelling fact: companies that take a proactive approach to supply chain risks spend 50% less on disruptions compared to those that only react after problems arise. And yet, 85% of global supply chains experience at least one disruption annually.

The first step toward proactive risk management is achieving clear visibility across the entire supply chain. After all, you can’t manage what you can’t see. This means mapping not just your direct suppliers but also uncovering and understanding the sub-tier suppliers that often fly under the radar. Bringing together procurement teams, risk managers, and business units ensures a unified approach, so everyone is ready to act when challenges arise.

Technology has become a game-changer for supply chain resilience. Companies using digital tools are twice as effective at managing risks. Tools like AI-driven monitoring systems can assess the financial health of suppliers, while real-time dashboards track quality metrics to catch potential issues before they snowball into major disruptions.

Building strong, trust-based relationships with suppliers – what some call "relationship capital" – is another cornerstone of resilience. By treating suppliers as partners and investing in their growth, businesses can create a foundation of collaboration that pays off during challenging times. This approach shifts the dynamic from merely transactional to truly strategic, enabling quicker recovery when the unexpected happens.

In a world where market conditions can change overnight, the companies that thrive are those that prioritize flexibility, transparency, and a commitment to continuous improvement. With only 10% of businesses fully equipped with the resilience capabilities needed to handle major disruptions, there’s a clear opportunity for organizations willing to take action. Start by mapping your critical products, defining risk thresholds, and implementing robust monitoring systems to set your supply chain up for long-term success.

FAQs

What steps can businesses take to identify and manage risks in their deep-tier suppliers?

To tackle risks in deep-tier suppliers effectively, businesses need a well-organized and forward-thinking strategy. Begin by mapping out your entire supply chain. This process can reveal weak points, particularly with overseas and deep-tier suppliers, where issues like counterfeit goods, subpar manufacturing practices, or even tampering might arise.

Use data analytics to keep a close eye on supplier performance and compliance in real time. Modern tools can help predict potential risks and rank them by priority, allowing for quicker, smarter decision-making. Equally important is fostering transparency and collaboration across all levels of your supply chain. These combined efforts can help businesses reduce disruptions and keep operations running smoothly.

Why is diversifying your supplier base important, and how can you do it effectively?

Diversifying your supplier base is a smart way to protect your business from potential risks like supply chain disruptions caused by natural disasters, political turmoil, or economic setbacks. When a company depends heavily on just one or a few suppliers, it leaves itself exposed to vulnerabilities. On the other hand, working with a broader network of suppliers strengthens resilience and helps ensure operations continue smoothly, even in the face of unexpected challenges.

To make diversification work, businesses can source from a variety of suppliers across different regions and industries. This might involve setting up supply chains that span multiple locations, collaborating with a mix of suppliers, or even exploring alternative transportation methods. By incorporating flexibility and redundancy into the supply chain, companies can adapt more effectively to disruptions. The key to success lies in proactive planning and consistently monitoring risks to stay ahead of potential issues.

How do AI tools help monitor supply chain risks in real-time?

AI tools play a key role in keeping supply chains running smoothly by monitoring risks in real time. They sift through massive amounts of data to spot potential disruptions, predict risks, and send out early warnings. This gives businesses the chance to act quickly and reduce the impact of any issues.

With AI, companies can better understand supplier performance, navigate geopolitical uncertainties, and tackle logistical hurdles. These insights help businesses make smarter decisions, keeping their supply chains strong and efficient.

モバイル/What's App/Wechat

モバイル/What's App/Wechat Eメール

Eメール 追加

追加