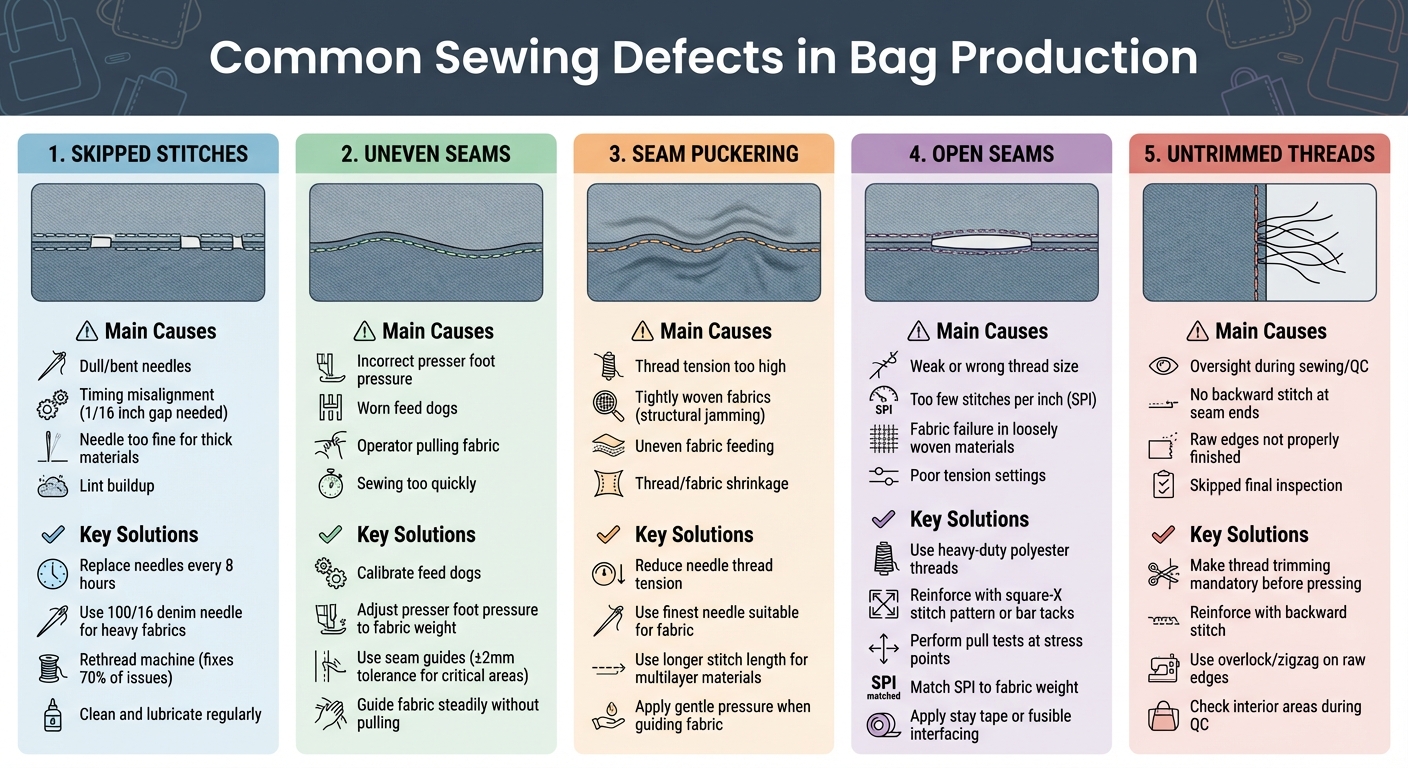

When producing bags, sewing defects like skipped stitches, uneven seams, puckering, open seams, and untrimmed threads can compromise durability and appearance. These issues not only affect functionality but also damage customer trust and brand reputation. Fixing these problems requires understanding their causes and applying targeted solutions during production. Here’s what you need to know:

- Skipped Stitches: Caused by dull needles, timing issues, or thick materials. Fix by replacing needles, adjusting machine timing, and rethreading.

- Uneven Seams: Result from fabric feeding problems or operator error. Address with proper machine calibration, presser foot adjustments, and seam guides.

- Seam Puckering: Stems from tension, fabric structure, or uneven feeding. Reduce thread tension, use appropriate needles, and ensure even fabric feeding.

- Open Seams: Caused by weak threads, poor stitching, or fabric failure. Prevent with reinforced seams, quality threads, and proper SPI (stitches per inch).

- Untrimmed Threads: Oversight during finishing. Require thread trimming and reinforce seams for a polished look.

Maintaining quality involves regular machine maintenance, precise stitch specifications, and thorough quality checks at every production stage. These steps ensure durable, well-crafted bags that meet customer expectations.

5 Common Sewing Defects in Bag Production: Causes and Solutions

Skipped Stitches: Causes and Fixes

Skipped stitches, those visible gaps in seams, aren’t just minor cosmetic flaws in bag production – they can seriously compromise the bag’s durability. Under heavy loads or when handles are tugged, these weak points can lead to structural failure.

What Causes Skipped Stitches

Skipped stitches often stem from a few key issues:

- Needle Problems: A dull, bent, or improperly installed needle is a common culprit. If the needle’s flat side isn’t correctly oriented or it’s not fully seated in the needle bar, the hook can’t properly lock the thread. To avoid this, replace needles every 8 hours of continuous sewing to maintain stitch quality and prevent fabric damage.

- Timing Misalignment: The needle and shuttle hook need to work in perfect sync. The hook must catch the thread loop at just the right moment as the needle rises. Ideally, the needle eye should sit about 1/16 inch below the hook tip when they’re adjacent. The gap between the hook and needle should be as thin as a single sheet of printer paper.

- Thick Materials: Bag production often involves multiple layers of canvas, interfacing, and stabilizers. Using a needle that’s too fine for these heavy fabrics can cause it to deflect, leading to skipped stitches. A 100/16 denim needle is typically the best choice for such materials.

- Machine Maintenance: Regular upkeep is essential for consistent stitch quality. Lint buildup in the bobbin area and feed dogs can interfere with thread movement, while an oversized or damaged throat plate hole may push fabric into the machine, disrupting loop formation. Excessive thread tension – whether top or bottom – can also prevent proper loop formation.

"Rethreading from scratch solves 70% of stitch problems – one skipped checkpoint throws off tension and ruins consistency." – SewingTrip

By addressing these common causes, you can keep your seams strong and reliable.

How to Fix Skipped Stitches

When skipped stitches occur, here’s how to get back on track:

- Start with the Needle: Replace the needle immediately if stitches are skipping. For heavy materials like canvas or webbing, opt for a denim or leather needle (size 100/16). Make sure the needle is fully inserted into the needle bar and the flat side is facing the correct direction.

- Check Machine Timing: Perform the "printer paper test" by manually rotating the handwheel and observing the hook tip’s position relative to the needle. The gap should match the thickness of a single sheet of paper, and the needle eye should be about 1/16 inch below the hook tip when they align. If timing is off, professional servicing can prevent significant production delays.

- Rethread the Machine: Both the upper and bobbin threads should be rethreaded from scratch, as this resolves 70% of stitch issues. Ensure the thread is properly seated in the tension discs and that the take-up spring moves the thread smoothly.

- Clean and Lubricate: Regularly clean your machine to remove lint and debris, especially after every project. Apply sewing machine oil to moving parts every 8 to 10 hours of use. This helps maintain timing accuracy and ensures smooth operation.

- Reinforce Seams: If skipped stitches have compromised a seam, re-sew over the affected section or redo the entire seam if necessary. Perform a pull test by gently tugging on the seam. If gaps widen without the thread breaking, it’s a structural issue that needs immediate attention. These steps not only fix the skipped stitches but also ensure the bag’s overall durability and quality remain intact.

Uneven Seams: Problems and Solutions

Uneven seams show up as irregular stitch lines and inconsistent allowances, which can weaken a bag’s structure. These issues go beyond just aesthetics – poor seams can create weak spots that lead to failure, potentially damaging your brand’s reputation.

When seam allowances are too narrow due to uneven stitching, the fabric becomes prone to fraying, and yarns may shift even if the stitches hold. On the other hand, allowances that are too wide can result in bulky areas that affect how the bag sits or drapes. For high-visibility areas like pocket openings and center lines, quality standards typically allow for a maximum offset of only ±2 mm.

What Causes Uneven Seams

The main culprits behind uneven seams are fabric drag and feeding problems. If the presser foot pressure is too high, it stretches the top layer of fabric; if it’s too low, the foot may bounce, causing a loss of control over the material [4, 17]. Worn feed dogs, lint buildup, or incorrect height settings for the material can also lead to irregular stitch lengths and wavy seams.

Operator error is another major factor. Pulling the fabric instead of guiding it, sewing too quickly, or failing to align midpoints – especially when sewing curves or gussets – can cause misaligned seams [4, 1]. Rapid sewing can also make the feed dogs move faster than ideal, creating ripples and uneven stitch spacing.

To identify if the issue stems from the feeding mechanism, technicians can cut across a seam and remove the thread. If one fabric layer is noticeably longer than the other, it indicates unequal feeding that needs to be corrected. Addressing these problems requires precise adjustments to restore uniformity.

How to Fix Uneven Seams

Fixing uneven seams involves a combination of machine adjustments and improved operator techniques.

- Calibrate the feed dogs: Make sure the feed dog teeth are sharp and set to pull fabric evenly. Check that the throat plate and presser foot have needle holes that are about twice the size of the needle to prevent fabric flagging [19, 18].

- Adjust presser foot pressure: Match the pressure to the fabric’s weight. Use a low-friction presser foot for materials prone to dragging, and find the right pressure to ensure an even feed without stretching or bouncing. For thicker assemblies with multiple layers, increasing the stitch length can help reduce friction and minimize pulls or ripples.

- Use seam guides and alignment marks: Set a maximum offset tolerance (±2 mm for critical areas) and add notches to patterns to ensure proper alignment. When sewing curved gussets, make small snips into the seam allowance – about ½ inch apart and ¼ inch deep – to help ease the fabric into the curve without distorting the seam line [4, 1].

- Train operators on proper techniques: Teach operators to guide the fabric steadily without pulling, allowing the feed dogs to handle the material. Maintaining a consistent, slower sewing pace prevents the feed dogs from moving too quickly and causing uneven stitches. Additionally, clipping or pinning midpoints and straight edges before sewing complex parts ensures proper alignment throughout [1, 19].

At JUNYUAN BAGS, these techniques are part of a meticulous quality control process, ensuring every bag is not only visually appealing but also built to withstand everyday use.

Seam Puckering: Causes and Fixes

Seam puckering shows up as wavy, uneven fabric along stitch lines, often giving off an impression of sloppy work. Beyond aesthetics, it can strain both the thread and fabric, increasing the risk of snapping or permanent warping. In durable items like sports bags, puckered seams can form folds that concentrate stress, weakening the structure under heavy loads.

This issue is particularly common with canvas and dense synthetic fabrics used in bag production. These materials have tightly woven yarns that get displaced by the needle and thread, causing surface distortions. To address the problem, it’s essential to first identify the specific type of puckering.

What Causes Seam Puckering

There are four main types of seam puckering, each with its own underlying cause:

- Tension puckering: This occurs when thread tension is too high, stretching the thread during stitching. Once the thread relaxes, it pulls the fabric into puckers.

- Inherent puckering (structural jamming): Found in tightly woven fabrics, this happens when there’s not enough room for the sewing thread. The needle and thread displace the warp and weft yarns, creating stress and distortion along the seam.

- Feed puckering: This happens when fabric layers are fed unevenly through the machine. The feed dogs may move the bottom layer faster than the presser foot allows the top layer to move.

- Shrinkage puckering: Caused by fabric or thread shrinking during laundering or pressing. This is common with cotton threads or when fabric components – like linings – shrink more than the outer material.

Other culprits include dull needles, which can snag fabric fibers, and improper interfacing that fails to stabilize the material. A dull needle might even make a popping sound as it struggles to pierce the fabric cleanly.

Pinpointing the type of puckering is the first step toward fixing the issue.

How to Fix Seam Puckering

To fix seam puckering, you’ll need to identify its cause first. Here’s how:

- For tension puckering, cut both the top and bottom threads of a few stitches without moving the fabric. If the puckering vanishes immediately, the tension is too high.

- For inherent puckering, remove the stitches from a section of the seam. If the fabric stays distorted even without the thread, structural jamming is to blame.

- For feed puckering, cut two perpendicular slits across a sewn seam and remove the thread between them. If one layer of fabric is longer than the other, uneven feeding caused the issue.

Once you’ve identified the cause, make the necessary adjustments. Reduce needle thread tension to the lowest setting that still produces a balanced stitch to prevent thread shrinkage. Use the finest needle and thread suitable for your fabric to minimize yarn displacement, especially with dense weaves. For multilayer materials, opt for a longer stitch length to reduce puckering by spacing out needle penetrations.

Zippers are a common trouble spot for puckering. Instead of pins, use fabric glue or double-sided tape to secure the fabric during installation. This prevents tiny ripples from forming. When guiding fabric through the machine, apply gentle pressure without pulling, allowing the presser foot and feed dogs to maintain even feeding.

Open Seams: Prevention and Repairs

Open seams – those gaps or breaks in stitching – can seriously compromise the durability of a bag, making it unusable and unsellable. These failures often start small, at stress points like handles or corners, but can quickly escalate into full seam bursts during use. For waterproof bags, even a tiny gap or perforation in the seam can lead to leaks and moisture damage. Knowing what causes these issues is key to preventing and fixing them effectively.

What Causes Open Seams

The most common reason for open seams is thread failure. This can occur due to weak threads, using the wrong thread size, or poor-quality materials. Another factor is having too few stitches per inch (SPI), which can result in "stitch cracking" under stress. In some cases, the stitching remains intact, but the fabric itself fails – especially if it’s loosely woven – causing the yarns to pull out or rupture. Other culprits include using the wrong needle size, poor tension settings, or improper machine timing during production.

How to Fix and Prevent Open Seams

Addressing open seams requires a combination of repair techniques and preventive measures. To fix a seam, turn the bag inside out, align and pin the edges, and backstitch along the original seam line. For high-stress areas, such as where handles attach to the bag, reinforce the seam with a square-X stitch pattern or bar tacks to add strength. Always opt for heavy-duty polyester threads, as they are more resistant to breaking under stress compared to cotton threads. For fabrics prone to seam slippage, consider using French seams or flat-felled seams, which add extra rows of stitching for durability.

Prevention starts with thorough quality control. Perform a pull test by applying gentle tension to stress points; if you notice any gaps or "grinning", it signals a structural issue. Match the SPI to the fabric weight to avoid seam cracking. Regularly check needle-looper timing and replace worn or damaged needles at the start of production. For added support, apply stay tape or fusible interfacing to the interior side of the seam to prevent yarns from pulling out. These steps are part of a rigorous quality control process, ensuring every bag is built to withstand daily use.

sbb-itb-1e6451b

Untrimmed Threads and Loose Ends: Finishing Problems

Untrimmed threads can speak volumes about production quality. Even if a bag is well-made structurally, loose threads poking out from seams can make it look incomplete. It’s not just about appearances – these threads can snag on clothing or other items, potentially causing the seams to unravel over time.

Heidi, the founder of Sew Heidi and an accomplished fashion designer, explains:

"Untrimmed threads refer to excess thread tails which can detract from the garment’s appearance and give the impression of poor craftsmanship. Honestly, this is most likely just because of oversight in the sewing or quality control process."

What Causes Untrimmed Threads

The main culprit behind untrimmed threads is oversight, either during sewing or final inspection. If thread trimming isn’t treated as a mandatory step before pressing and packing, these stray ends can easily go unnoticed. Another common issue is skipping the backward stitch at the start and end of seams, which can leave them less secure. For bags made from woven materials, raw edges that aren’t properly finished – using techniques like serging or zigzag stitching – can fray over time, creating visible fiber ends. The problem can get worse if operators fail to perform quick checks on their work before it reaches the final inspection stage. Tackling these issues is crucial for achieving a polished and professional product.

How to Achieve Clean Finishing

To create a clean and polished finish, make thread trimming a required step before pressing. Train operators to reinforce all major seams with a backward stitch, especially in high-stress areas like handle attachments and strap connections. Quality control teams should pay close attention to interior areas – pocket bags, linings, and internal seams – where loose threads are often overlooked. For fabrics that tend to fray, using overlock or zigzag stitches on raw edges can prevent fibers from breaking down over time. When working with laminated or coated materials, using a walking foot or a Teflon-coated presser foot can help ensure smooth fabric feeding, minimizing irregular stitching that might otherwise require manual fixes.

Maintaining Quality in Bag Production

Ensuring top-notch quality in bag production starts long before the first stitch is sewn. Quality control is a continuous process that spans every stage – pre-production, in-process, and post-production. As one expert aptly put it:

"QC isn’t just a final inspection; it’s an ongoing commitment that starts from the very first design to the moment the bags leave the factory."

By taking these proactive measures, manufacturers can ensure that every bag aligns with the rigorous standards established during defect diagnosis and repair.

Quality Control Steps

Regular machine upkeep is a cornerstone of defect prevention. A well-maintained checklist should include tasks like needle replacements and machine calibration to avoid issues like skipped stitches or fabric damage. Tech packs must outline precise details, such as stitches per inch (SPI), thread type, seam allowance width, and stitch type, to eliminate inconsistencies. Operators should be trained to perform quick quality checks as their work progresses. For instance, using a ruler during spot checks helps confirm that SPI matches the required specifications. In areas prone to stress, like handle attachments, performing pull tests is essential – any seam grin indicates a potential structural problem. Additionally, ensure the needle size and point are appropriate for the fabric being used.

These quality control measures not only prevent defects but also enhance the durability and performance of each bag.

Adding Defect Checks to Production

Incorporating zone-based inspections into production can significantly improve defect management. For example, Zone A focuses on high-visibility areas like pocket openings and center seams, where defects are completely unacceptable. Meanwhile, Zone C, which includes interior linings, may tolerate minor cosmetic flaws as long as structural integrity is preserved. At JUNYUAN BAGS, quality protocols include added measures like UV-resistant coatings for outdoor durability and seam-sealed stitching to prevent water penetration.

To streamline defect documentation, use detailed, zoomed-in photos instead of vague notes. This approach provides clear visual guidance for corrections. Additionally, conducting root cause analyses can pinpoint whether issues stem from machine malfunctions, training gaps, or material inconsistencies. Identifying problems early helps prevent them from escalating further down the production line.

Conclusion

Sewing defects – like skipped stitches, uneven seams, puckering, open seams, or loose threads – can seriously impact a product’s durability and damage a brand’s reputation. For bags, areas such as handles, seams, and zippers face the most stress, making top-notch construction essential to avoid customer dissatisfaction.

If left unaddressed, these flaws compromise product reliability. The key to avoiding defects lies in implementing quality checks at every production stage, not just during the final inspection. Clear and detailed tech pack specifications – covering stitch type, stitches per inch (SPI), and thread requirements – help eliminate guesswork. Regular machine maintenance, choosing the right needles, and conducting in-process checks can catch problems early. By focusing on solutions like consistent machine calibration and proper needle selection, manufacturers can protect both the product’s structure and the brand’s reputation. These steps not only prevent expensive rework but also ensure a durable, high-quality product.

Tackling these challenges demands both thoughtful design and careful production management. At JUNYUAN BAGS, every custom bag – whether it’s a sports bag, travel bag, or tool bag – undergoes rigorous inspections, including zone-specific checks and root cause analyses, to meet the highest standards.

FAQs

What can I do to avoid skipped stitches when sewing thick fabrics for bags?

When sewing thick bag materials, achieving smooth, even stitches takes a little extra care. Start by using a walking foot along with a heavy-duty needle (size 12–14) to handle the dense fabric effectively. Double-check that your sewing machine is threaded properly, then adjust to a longer stitch length and slightly loosen the thread tension. For best results, slow down your sewing speed – this allows the needle to glide through the material without skipping stitches. Following these steps will help you produce neat and professional-looking seams on tough fabrics.

How can I achieve straight and even seams when making bags?

Achieving straight, even seams is essential for creating bags that look polished and professional. Start by ensuring your sewing machine is set up correctly: adjust the tension and keep a steady stitching speed to avoid puckering or uneven stitches. For thicker materials, try using a slightly longer stitch length to help the fabric glide smoothly. Don’t forget to choose the right needle size, like a size 12 or 14 universal, to avoid skipped stitches.

Using a walking foot can be a game-changer. It helps feed all fabric layers evenly, preventing shifting and keeping your stitches straight. While sewing, gently smooth the layers with your fingers to reduce bulk and ensure proper alignment. Once you’ve completed the stitching, press the seams with an iron or lightly tap them with a rubber mallet (using a protective layer) to give them a clean, professional finish.

These techniques, paired with the right tools, are how manufacturers like JUNYUAN BAGS achieve durable and visually impeccable designs.

What causes seam puckering in bags, and how can I fix it?

Seam puckering shows up as ripples or bunching along a stitched seam, giving it an uneven or less-than-polished look. To check if you’re dealing with puckering, press the seam with an iron. If the ripples persist, the issue likely stems from fabric structure or tension problems. This tends to happen with heavier materials like canvas, leather-like fabrics, or areas reinforced with interfacing, especially near corners or stress points.

To address seam puckering, follow these steps:

- Re-thread your machine: Ensure both the top thread and bobbin are set up correctly, and check that the bobbin is wound evenly.

- Choose the right needle: Use a sharp needle designed for your material, such as a universal or leather needle.

- Adjust tension settings: Lower the tension for lightweight fabrics, and increase it for heavier ones.

- Lengthen your stitches: Set the stitch length to around 3–4 mm for a smoother finish.

- Use specialty presser feet: A walking foot or Teflon foot can help with thick or slippery materials.

- Stabilize delicate fabrics: Apply interfacing to prevent shifting or stretching.

- Let the feed dogs do the work: Avoid pulling the fabric manually; let the machine guide it naturally.

- Press the seam: Use the correct iron setting for your fabric to smooth out any lingering ripples.

By taking these steps, you can achieve smooth, professional-looking seams, ensuring your custom bag designs have a polished and high-quality finish.

モバイル/What's App/Wechat

モバイル/What's App/Wechat Eメール

Eメール 追加

追加