3D-knitted bags are transforming how bags are made and used. These bags are crafted using digital designs and computerized knitting machines, producing seamless, durable, and lightweight structures. Unlike traditional methods, this process minimizes fabric waste – cutting it by up to 90% – and uses eco-friendly materials like recycled polyester or bamboo textiles.

Key benefits include:

- Customization: Designs, patterns, and features tailored to personal needs.

- Comfort: Elastic fabrics distribute weight evenly and reduce strain.

- Style: Modern designs with options for intricate patterns and bold colors.

- Eco-conscious production: Reduced waste, water, and energy usage.

Leading the way, JUNYUAN-TASCHEN offers custom 3D-knitted bags with a focus on recycled materials, quick prototyping, and strict quality control. These bags are perfect for daily commutes, gym sessions, or weekend trips while addressing growing consumer demand for sustainable products.

3D Knitting: Who does this stuff?

How 3D Knitting Technology Works

How 3D Knitting Technology Creates Seamless Bags

The 3D Knitting Process

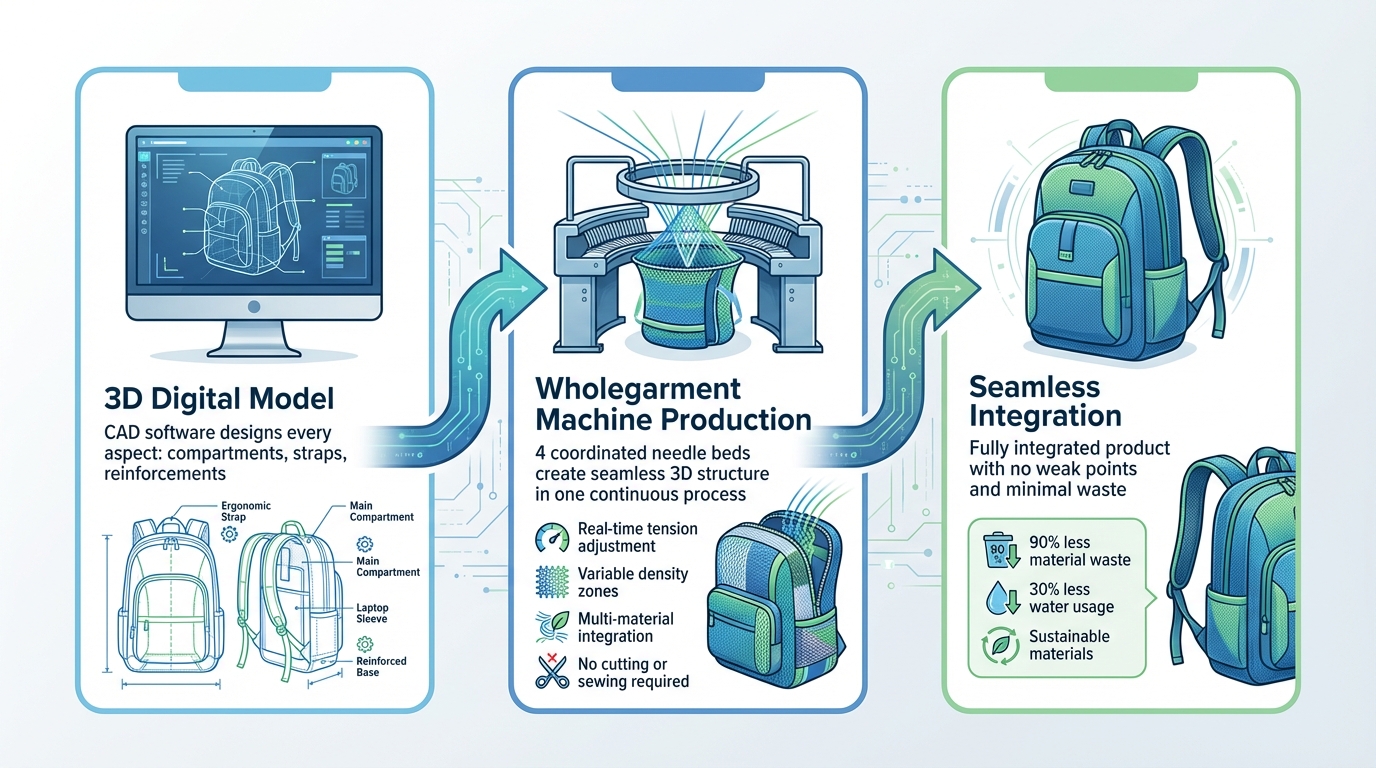

It all begins with a three-dimensional digital model designed using CAD (computer-aided design) software. Designers meticulously plan every aspect of the product, from compartments to straps and reinforcements, creating a detailed digital blueprint.

Once the design is ready, computerized knitting machines, like Wholegarment machines, take over. These machines interpret the digital instructions and execute them with precision. They control the actions of various needles across multiple coordinated needle beds – usually four – to craft a seamless, three-dimensional structure in one continuous process. No cutting or sewing is involved.

The result? A fully integrated product with no weak points and minimal waste. This streamlined production method also opens the door for advanced material customization.

Technical Capabilities

One standout feature of 3D knitting is its ability to adjust tension and stitch patterns in real time. This allows for variable density zones, which strengthen critical areas like bottom panels or handle attachments, while keeping other sections lightweight.

Another impressive capability is multi-material integration, which lets manufacturers combine different yarns during the knitting process. For example, they can incorporate moisture-wicking fibers, extra padding, or even conductive elements directly into the design. This isn’t an afterthought – it’s built into the knitting process itself.

Additionally, the technology supports the use of sustainable materials, such as bamboo textiles that use 30% less water and require no pesticides, or recycled polyester. This aligns with the increasing consumer demand for eco-friendly options.

Key Benefits for Men’s and Women’s Bags

These advancements in bag-making technology bring a host of benefits that cater to modern lifestyles.

Versatility for Different Activities

3D-knitted bags are designed to keep up with your daily needs. Their flexible design allows one bag to perform multiple roles – whether you need a business tote, a backpack, or even an evening clutch, these bags can do it all seamlessly. Integrated pockets and compartments are knitted directly into the bag, offering organized storage for essentials like your phone, Brieftasche, and keys – without the added bulk of traditional sewn-in dividers. Plus, the flexible structure naturally adjusts to different body types, making it a practical choice for just about anyone.

And it’s not just about functionality – comfort is a key priority, too.

Comfort and Ergonomics

The elastic fabric used in 3D-knitted bags provides natural cushioning and evenly spreads weight, reducing strain on your shoulders. Features like jersey outer layers and mesh weaves improve breathability, keeping you cool and comfortable even during long commutes or active days. Unlike rigid materials, the flexible construction moves with you, preventing heat buildup and moisture accumulation. Additional details, like padded shoulder straps and cushioned panels, further enhance comfort by evenly distributing weight across your shoulders.

This thoughtful design pairs perfectly with the stylish options these bags offer.

Style and Design Options

3D knitting opens up a world of design possibilities that traditional methods can’t match. From intricate jacquard patterns to sleek, modern color blocking, these bags are crafted as a single piece, offering a variety of carrying styles – whether hand-held, attached, or wearable. Certain designs feature ribbed mesh structures with pleated details, available in bold colors and adjustable strap lengths. The adaptive mesh structure adds a practical yet stylish touch by subtly revealing the bag’s contents under tension.

Personalization is another standout feature. With 78% of consumers seeking customized products, 3D knitting delivers by offering varied elastic levels, intricate patterns, and adaptable forms that cater to both individual style and functional needs.

sbb-itb-1e6451b

Sustainability and Material Efficiency

3D knitted bags go beyond just offering style and comfort – they directly address some of the most pressing environmental challenges in the textile industry. Consider this: the industry produces a staggering 92 million tons of waste every year and is responsible for 20% of industrial wastewater globally. By rethinking traditional manufacturing methods, 3D knitting significantly reduces these impacts.

The magic lies in its seamless production process. Unlike conventional methods that involve cutting and sewing, 3D knitting creates bags in one continuous operation. This eliminates fabric waste almost entirely. On top of that, this process is incredibly efficient, using less water and energy. The near-net-shape manufacturing approach ensures the final product is nearly complete straight off the machine, cutting material waste by up to 90% compared to traditional techniques. Even better, water usage drops by 30%, and the process contributes to lowering the industry’s 10% carbon footprint.

Material choices amplify the eco-friendly aspect. For instance, one pioneering brand has introduced a handbag collection crafted entirely from recycled materials, including ocean-bound plastics and recycled polyester (rPET) thread. This innovative use of recycled components creates a fabric that is not only durable and washable but also structured – setting a new standard for reusing marine plastics.

This approach aligns perfectly with consumer preferences. Today, 78% of consumers prefer brands that prioritize sustainability, reflecting the values of a textiles market now worth $1.05 trillion. The ability to produce bags on demand further tackles another big issue: overstock waste. In the fast fashion world, 60% of garments end up in landfills within a few years. By producing only what’s needed and extending the lifespan of products, 3D knitted bags offer a smarter, more responsible way to meet the growing demand for sustainable manufacturing.

Custom 3D Knitted Bags with JUNYUAN-TASCHEN

JUNYUAN BAGS takes 3D knitting to the next level by offering custom solutions that blend style, function, and eco-consciousness. With a focus on Flyknit handbags – crafted from recycled fibers and designed to minimize waste by up to 60% during production – they create lightweight, breathable bags that cater to both individual and business needs. Their approach combines innovative design with sustainable practices, ensuring each bag is as unique as its user.

Anpassungsoptionen

JUNYUAN BAGS provides a wide range of customization choices, allowing every detail of a 3D knitted bag to be tailored to specific preferences. Logos and graphics can be applied using techniques like embroidery, sublimation printing, leather patches, silk printing, rubber logos, or metal logos. The design flexibility extends to the bag’s shape and size, ensuring it fits everything from daily essentials to travel gear.

"Custom design, logo, size, material, pattern, are all available at JUNYUAN Bags." – junyuanbags.com

Material options are extensive, including RPET, waterproof nylon, vegan leather, breathable mesh, genuine leather, quilted fabric, eco-friendly textiles, durable nylon, PVC, PU leather, denim, and oxford. Customers can also select from a broad color spectrum, even specifying Pantone color numbers for precise matching. Functional features like compartments, laptop sleeves, ventilated sections, RFID-blocking technology, and hydration systems can be seamlessly incorporated to meet various lifestyle or athletic demands.

Prototyping and Manufacturing Process

JUNYUAN BAGS uses cutting-edge digital tools to bring ideas to life. With advanced software like Shima Seiki‘s SDS®-ONE APEX series and APEXFiz®, they create virtual samples that mimic every stitch, allowing designers to refine colors, patterns, and structural details before production begins. This process not only accelerates development but also reduces costs and aligns with sustainable practices.

"From concept sketches to final production: – Logo application (embroidery, printing) – Material selection & sourcing – Structural engineering – Prototyping in 7-10 days" – junyuanbags.com

Once the design is finalized, physical samples are produced within 7–10 days. After approval, bulk production begins under strict quality control measures. JUNYUAN BAGS oversees every stage – from sourcing materials to delivering the final product – offering a seamless private label manufacturing experience.

Zertifizierungen und Normen

JUNYUAN BAGS adheres to internationally recognized standards, including BSCI, CE, RoHS, and ISO9001. These certifications guarantee consistent quality, ethical production practices, and a strong focus on environmental responsibility, ensuring every bag meets the highest expectations.

Schlussfolgerung

3D knitted bags are changing the way we think about bag design. By eliminating weak points through seamless construction, they offer improved durability and comfort. Plus, they tackle environmental concerns by reducing waste, making them a smart choice for everything from gym sessions to daily commutes and weekend getaways.

These bags aren’t just tough – they’re versatile. The technology behind them ensures they last longer while using fewer materials, striking a perfect balance between practicality, style, and eco-friendliness.

JUNYUAN BAGS takes this innovation a step further with customizable options. From the materials used to the smallest design details, everything can be tailored to fit personal preferences. Their use of recycled fibers and focus on waste reduction prove that forward-thinking design and environmental responsibility go hand in hand.

With certifications like BSCI, CE, RoHS, and ISO9001, JUNYUAN BAGS ensures consistent quality. They offer quick prototyping and oversee every step of the manufacturing process, whether you’re ordering a single custom bag or a large production batch. The result? Bags that excel in design, durability, and eco-consciousness.

Combining durability, sustainability, and personalization, these bags deliver on every front – comfort, style, versatility, and a reduced environmental footprint.

FAQs

How does 3D knitting help minimize waste during bag production?

3D knitting technology offers a smarter way to produce bags with almost no waste. Instead of relying on traditional methods that involve cutting and sewing – often leaving behind piles of fabric scraps – this method creates bags in a single, seamless process. The result? Up to 90% less material waste. Beyond being eco-friendly, this technique delivers precise, high-quality designs while keeping its impact on the environment to a minimum.

What are the customization options for 3D-knitted bags?

3D-knitted bags bring a world of personalization to the table, allowing you to tailor them to your style and preferences. From a broad selection of colors to the option of adding private label branding, the possibilities are designed to make your bag uniquely yours. You can even request specific design features to improve both the appearance and functionality of your bag.

Whether you’re looking for something practical for daily use or a standout piece for special occasions, these customization options ensure your bag fits your needs and showcases your personality.

How do 3D-knitted bags improve comfort and support?

3D-knitted bags are crafted to align with your body’s natural shape, offering better comfort and support. Thanks to the specialized knitting process, these bags feature a flexible structure that helps minimize pressure points and reduces strain, making them easier to carry for long periods.

What sets these bags apart is the elasticity of the 3D-knitted material. It stretches and moves with you, providing a secure fit that complements your natural movements. This combination of comfort and adaptability makes 3D-knitted bags a smart and stylish option, whether you’re using them daily or for more active pursuits.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD