Recycled PET (rPET) transforms plastic waste, like bottles, into durable fabric for sports bags. It’s tough, water-resistant, and reduces waste while cutting energy use by 59% and CO₂ emissions by 32% compared to virgin polyester. Each ton of rPET saves 61,000 bottles from landfills or oceans. With comparable strength to traditional materials, rPET meets the demands of active lifestyles and aligns with eco-conscious consumer preferences. Manufacturers like SACOS DE JUNYUAN are leading the way by offering custom rPET designs tailored for athletes and brands prioritizing sustainability. rPET isn’t just a material – it’s a smarter choice for performance and the planet.

Durability and Eco Benefits: What rPET Offers

Built to Handle Active Lifestyles

Sports bags go through a lot – constant use, rough handling, and exposure to the elements. That’s why they need to be tough. The recycling process that turns plastic bottles into rPET fibers ensures these bags don’t just look good but also perform well. These fibers maintain their original strength, making the fabric highly resistant to abrasion and wear. Plus, rPET fabric is stain and water-resistant, which means spilled drinks, muddy shoes, or damp gear won’t ruin your bag anytime soon.

JUNYUAN BAGS, with over 15 years of expertise in crafting custom backpacks, has embraced rPET for its durability. Their experience shows that rPET keeps sports bags in great shape for much longer than traditional materials, reducing the need for constant replacements. But durability isn’t the only reason rPET stands out – it’s also a smarter choice for the planet.

A Boost for the Environment

While rPET excels in durability, it also delivers important environmental benefits. For one, it’s far less water-intensive to produce compared to traditional textiles. Given the increasing concerns over water shortages worldwide, this is a meaningful advantage.

Then there’s the issue of plastic waste. Every year, billions of plastic bottles end up in landfills or polluting oceans. By transforming these bottles into rPET sports bags, we’re giving this waste a new purpose and keeping it out of the environment. What’s even better? rPET is recyclable. Old or worn-out rPET products can be repurposed into fresh items, creating a cycle that minimizes waste.

For businesses, switching to rPET bags isn’t just an eco-friendly move – it’s a smart branding choice. Consumers today want greener options, and offering products made from rPET aligns with that demand. Plus, it demonstrates a commitment to reducing plastic waste, which can enhance a company’s reputation and environmental impact.

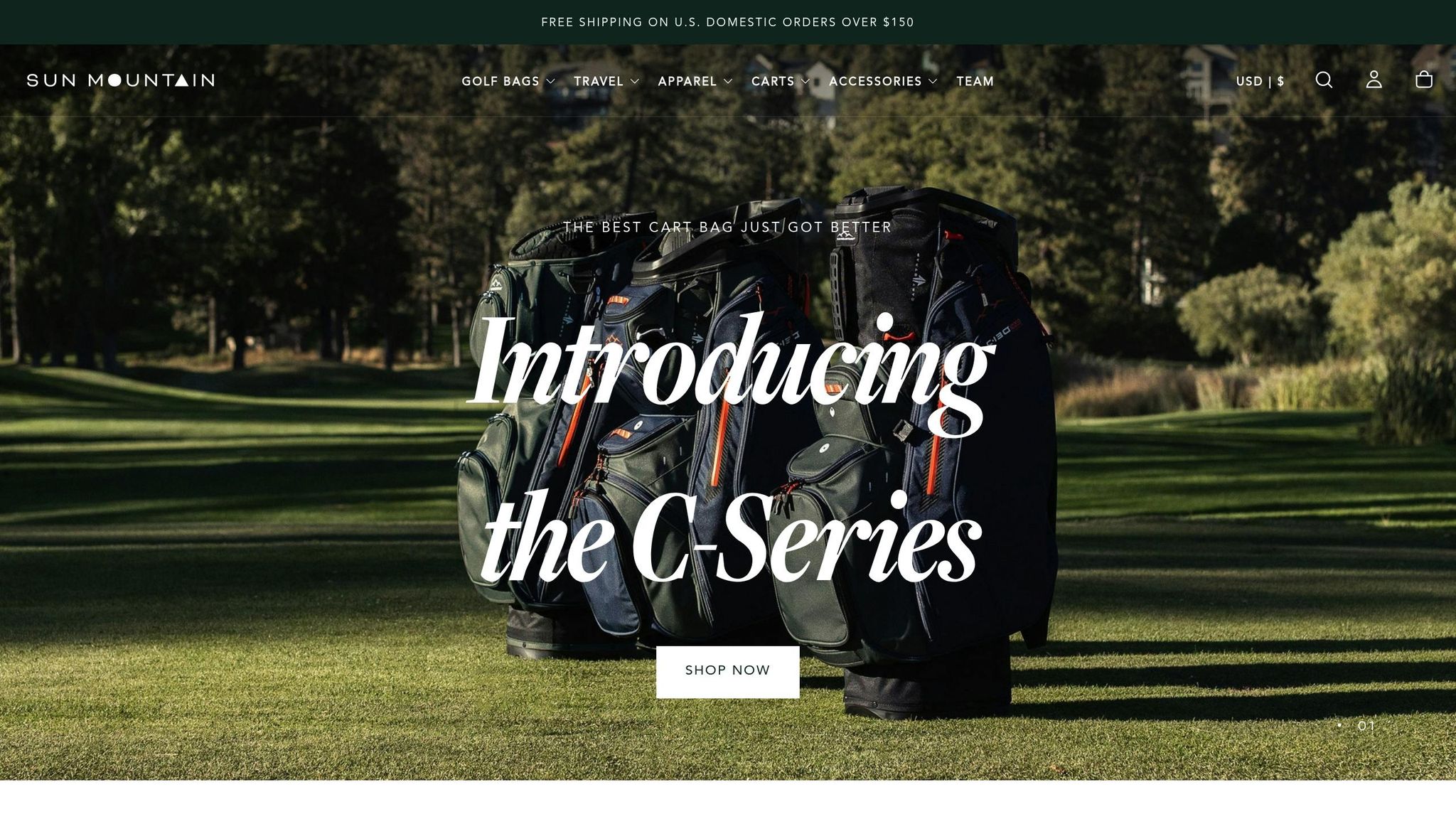

Eco-Lite Golf Bag, Made With Recycled Plastic Bottles ♻️ By Sun Mountain Sports

How rPET Works in Sports Bag Design

rPET has become a go-to material for sports bags, offering both durability and an eco-friendly edge. Its use in design not only benefits the environment but also enhances bag performance in demanding conditions.

Main Fabric, Straps, and Linings

Recycled bottles are transformed into rPET fibers, which are then used to create the main body fabric of sports bags. This material stands out for its resistance to wrinkles, shrinking, and fading, making it a practical choice for bags that endure tough environments. Whether it’s a gym bag tossed around in locker rooms or a tennis bag left out in the sun, rPET helps ensure the bag lasts longer.

Straps and handles also benefit significantly from rPET’s properties. Its strong resistance to abrasion means shoulder straps can handle heavy loads without fraying, even after repeated use. This is particularly important for bags carrying bulky items like shoes, water bottles, or sports gear. Inside, the linings are designed to resist tearing, even when subjected to heavy contents.

Water-Resistant and Quick-Drying Features

One standout feature of rPET fibers is their water resistance, which helps keep your gear dry in wet conditions. Whether it’s rain or a damp locker room floor, the material prevents moisture from seeping in. Plus, rPET dries faster than natural fibers like cotton, reducing the chance of musty odors or mold forming. For example, a pickleball bag can handle morning dew without staying damp, and a swimming gear bag won’t remain wet hours after use.

Custom Blends for Better Performance

Manufacturers often blend rPET with other fibers to tailor its properties for specific needs. Adding a touch of spandex, for instance, introduces stretch, while rPET-cotton blends create a softer texture without sacrificing strength. These combinations work well for bags that need to balance durability with a polished appearance, such as gym bags for corporate programs or team bags for school sports.

For more demanding uses, specialized blends can enhance strength and flexibility further. JUNYUAN BAGS, for example, uses these techniques to create sports bags designed to meet the unique needs of various activities. By adjusting the material properties, manufacturers ensure that each bag performs as intended while staying aligned with sustainable practices. These custom blends highlight how rPET can seamlessly combine functionality with eco-conscious design.

sbb-itb-1e6451b

Custom Manufacturing with rPET

Turning discarded plastic bottles into high-quality sports bags involves a mix of smart production techniques and thoughtful design. Knowing how rPET is made and what it offers in terms of design can help businesses and individuals make smarter choices when planning custom sports bag projects.

From Bottles to Bags: The rPET Production Process

The process starts with collecting and sorting post-consumer PET bottles, which are thoroughly cleaned to remove any impurities. After cleaning, the bottles are shredded into small flakes, melted, and then transformed into fibers. These fibers are spun into yarn and woven or knitted into fabric that’s ideal for sports bags. This approach doesn’t just keep plastic waste out of landfills – it also uses significantly less energy compared to making virgin polyester.

In fact, producing rPET can cut energy use by up to 50% and greenhouse gas emissions by as much as 79% compared to virgin polyester. It also requires much less water than cotton, making it a more environmentally friendly option. The production process includes rigorous cleaning, controlled melting, and precise fiber extrusion, along with quality checks to ensure strength, colorfastness, and chemical safety. These steps guarantee a high-quality material ready for custom designs.

Custom Designs for Every Need

rPET offers flexibility for customization, whether for branding or functionality. Businesses can add custom logos or slogans, while individuals might request features like adjustable straps, extra compartments, or specialized linings. Manufacturers can even tweak material blends to improve performance for specific sports or activities.

When choosing rPET for custom sports bags, factors like durability, specific design needs, and budget come into play. The environmental benefits – like reduced energy and water use – also add value by boosting brand image and sustainability efforts.

SACOS DE JUNYUAN: Your Partner in Custom Sports Bags

JUNYUAN BAGS uses rPET to create innovative and custom sports bag solutions. They offer designs tailored to various activities, with options for custom logos, colors, materials, and patterns.

Working with JUNYUAN BAGS means access to expert advice on rPET materials, advanced customization options, and efficient production processes. They even provide free design services, covering everything from material selection to logo placement, ensuring a smooth experience for both businesses and individual clients in the United States. Their full-service OEM and ODM capabilities allow for complete customization, from initial concept to final product.

While rPET can sometimes cost a bit more than virgin polyester due to collection and processing expenses, it often leads to lower overall production costs thanks to reduced energy and water use. Beyond cost savings, using rPET enhances brand reputation and can help secure green certifications, meeting the rising demand for sustainable products. Brands like Patagonia, Veja, and Ganni have already proven rPET’s potential in creating durable, eco-friendly products. This growing industry trend points to a promising future for custom sports bag manufacturing.

Conclusion: Why rPET Is the Future of Sports Bags

Recycled PET (rPET) brings together strength, eco-consciousness, and adaptability, making it a standout choice for the modern sports bag industry. By using 59% less energy and cutting CO₂ emissions by 32% compared to virgin polyester, rPET offers a way to achieve top-tier performance while staying environmentally responsible.

The numbers speak for themselves: every ton of rPET saves 61,000 plastic bottles, and recycling just 2.2 pounds of PET reduces CO₂ emissions by more than 7 pounds. For sports bag manufacturers and their customers, this means real environmental impact without sacrificing the durability needed for intense, everyday use. Plus, its proven strength opens the door to a wide range of design possibilities.

rPET also stands out for its customization potential. It easily accommodates dyeing, fiber blending, and adjustments for various bag components, making it simple for manufacturers to craft products tailored to individual preferences. This adaptability allows brands to meet the rising demand for sustainable goods while maintaining the high-performance standards athletes rely on.

JUNYUAN BAGS is leading the charge in this sustainable shift, offering Custom rPET Backpacks and specialized design services to help businesses transition to eco-friendly materials. With over 15 years of manufacturing experience, JUNYUAN combines expertise with a commitment to greener practices. Their free design services and OEM capabilities make it seamless for brands to embrace rPET without compromising on quality or vision.

As the industry moves forward, materials that offer both durability and environmental benefits will shape its future. With increasing regulations and a growing number of eco-conscious consumers, rPET isn’t just a passing trend – it’s a key step toward adopting circular economy practices in bag manufacturing. Companies that embrace rPET position themselves as leaders in sustainability, appealing to customers who prioritize eco-friendly choices.

For businesses ready to make the leap, the path is clear: work with experienced manufacturers who understand the technical demands of rPET while ensuring design flexibility. With its proven durability, measurable environmental advantages, and endless customization options, rPET is undoubtedly the future of sports bag manufacturing.

FAQs

Why is recycled PET a great choice for making sports bags?

Recycled PET (rPET) is a fantastic option for sports bags because it combines strength with an eco-friendly approach. Made by repurposing plastic bottles and other PET products, rPET helps cut down on waste while reducing the demand for new raw materials. This, in turn, helps lessen the environmental footprint of manufacturing.

Sports bags crafted from rPET are not just durable and built to last – they also encourage more environmentally conscious choices. This makes them a great fit for athletes and businesses aiming to pair performance with a greener mindset. JUNYUAN BAGS offers custom sports bags made with materials like rPET, delivering high-quality designs tailored to meet both personal and corporate needs.

What makes recycled PET (rPET) an ideal material for durable and high-performing sports bags?

Recycled PET (rPET) is a smart option for sports bags, combining strength with an environmentally conscious edge. Crafted from recycled plastic bottles, rPET is built to handle the rigors of daily use while retaining the durability needed for sports and outdoor adventures.

Beyond its resilience, rPET is lightweight and water-resistant, offering reliable protection for your gear in different conditions. Choosing rPET means less waste and fewer resources used in production, supporting eco-friendly efforts without sacrificing quality or functionality. It’s a practical choice that benefits both athletes and the planet.

What customization options are available for recycled PET sports bags, and how does the process work?

JUNYUAN BAGS offers a simple way to design custom sports bags crafted from recycled PET (rPET). You can tweak essential details like logos, sizes, materiais, and patterns to create a bag that perfectly suits your needs.

Whether you’re an individual wanting a one-of-a-kind design or a business looking to highlight your brand, their process delivers a personalized, sturdy, and environmentally conscious product. Just share your vision, and they’ll take care of the rest, providing a high-quality, sustainable option that truly stands out.

Telemóvel/What's App/Wechat

Telemóvel/What's App/Wechat E-Mail

E-Mail ADD

ADD