Global reporting standards like GRI (Global Reporting Initiative) are transforming the bag manufacturing industry by demanding transparency in environmental, social, and economic impacts. These standards help manufacturers track raw materials, labor practices, and emissions across complex supply chains. For example, bag manufacturers must now comply with updated GRI Universal Standards (effective January 1, 2023), which include mandatory reporting on human rights and environmental due diligence. Upcoming sector-specific standards, such as the GRI Textiles and Apparel Sector Standard (set for release in Q2 2026), will add further guidance for addressing industry-specific challenges like labor rights and waste reduction.

Key Takeaways:

- GRI Standards: The most widely adopted framework, focusing on universal, topic-specific, and sector-specific reporting.

- Supply Chain Transparency: Manufacturers must trace materials from origin to production, even beyond direct suppliers.

- Compliance Challenges: Tracking Scope 3 emissions, managing fragmented supply chain data, and ensuring fair labor practices are major hurdles.

- Tools for Compliance: Digital traceability systems and certifications (like BSCI, ISO 9001) can simplify reporting.

- Market Impact: Buyers increasingly demand proof of sustainable practices, making compliance a competitive necessity.

For manufacturers like JUNYUAN BAGS, integrating these standards into operations not only ensures compliance but also builds trust with stakeholders and opens new market opportunities.

Sustainability Reporting with the GRI Standards (3 SIMPLE STEPS)

Major Global Sustainability Reporting Standards for Bag Manufacturing

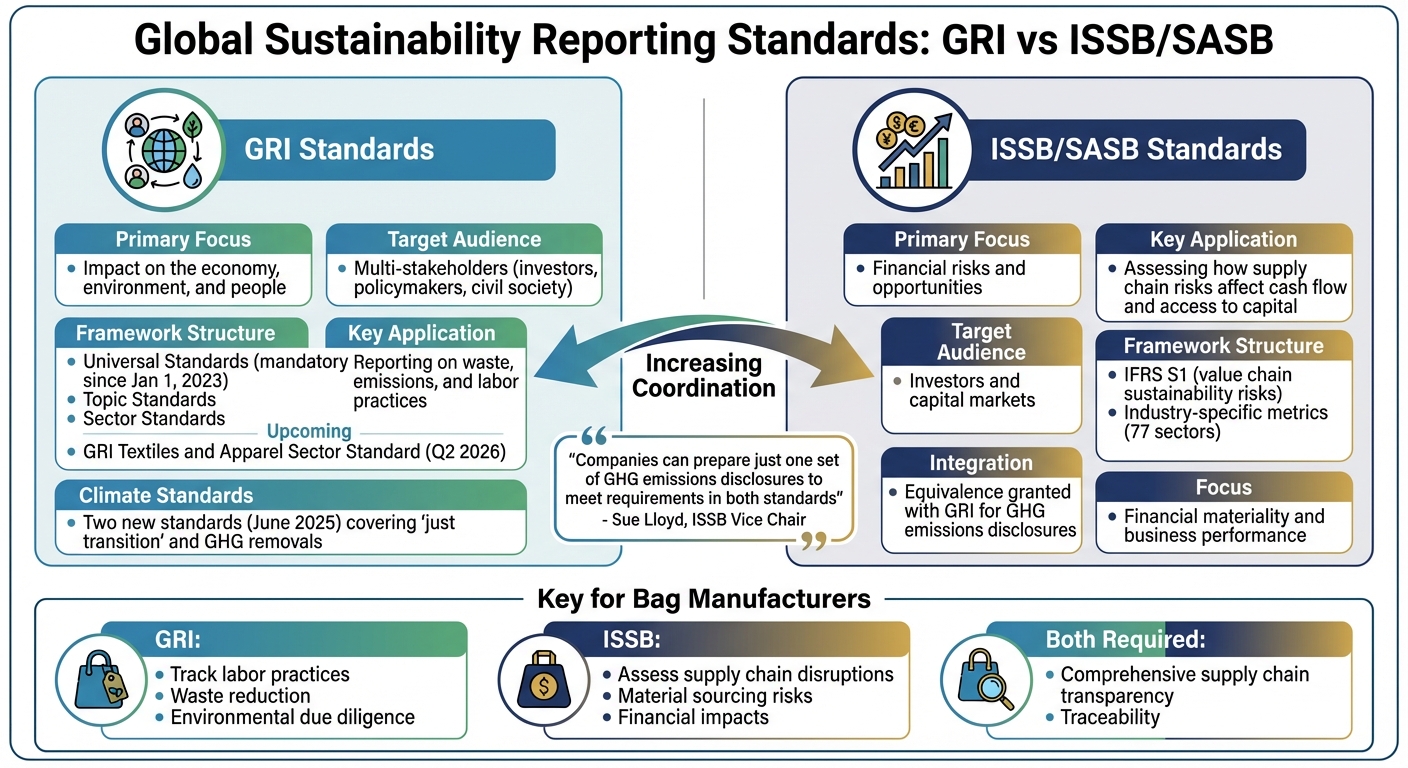

GRI vs ISSB Standards Comparison for Bag Manufacturing

Global standards are shaping how bag manufacturers address environmental and financial accountability, ensuring transparency and responsibility across operations.

GRI Standards: Universal, Sector, and Topic-Specific Frameworks

The Global Reporting Initiative (GRI) offers a modular framework to guide organizations in sustainability reporting. Its Universal Standards apply to all industries, covering general disclosures and human rights due diligence, which became mandatory on January 1, 2023. Meanwhile, Topic Standards focus on specific areas like waste management or labor practices, and Sector Standards address challenges unique to specific industries.

For bag manufacturers, the upcoming GRI Textiles and Apparel Sector Standard is a key milestone. Set for release in Q2 2026, this standard is being developed by a 21-member global working group. It will provide guidance on addressing labor rights risks, reducing greenhouse gas emissions, and managing waste.

Additionally, two climate-focused standards introduced in June 2025 require companies to report on "just transition" principles, greenhouse gas removals, and energy use across their entire value chain. Robin Hodess, CEO of GRI, highlighted the broader implications of these standards:

"Climate change is a deeply human issue, as much as it is an environmental one, and these new GRI Standards are unique in bringing these dimensions together".

While GRI emphasizes external impacts on society and the environment, other frameworks focus on how these issues influence financial performance.

ISSB and SASB Alignment for Financial Materiality

En International Sustainability Standards Board (ISSB) and Sustainability Accounting Standards Board (SASB) frameworks prioritize financial materiality – how sustainability issues affect a company’s cash flow, financial health, and access to capital. SASB, for instance, identifies industry-specific sustainability concerns across 77 sectors. For bag manufacturers, this includes factors like supply chain disruptions and challenges in sourcing materials. Under IFRS S1, companies must disclose sustainability risks throughout their value chain.

There’s also increasing coordination between these frameworks. Sue Lloyd, Vice Chair of ISSB, explained:

"We are delighted that the GRI have granted equivalence to IFRS S2 Climate-related Disclosures for disclosures of GHG emissions under GRI 102. This will enable companies to prepare just one set of GHG emissions disclosures… to meet the requirements in both standards".

| Standard | Primary Focus | Target Audience | Key Application |

|---|---|---|---|

| GRI Standards | Impact on the economy, environment, and people | Multi-stakeholders (investors, policymakers, civil society) | Reporting on waste, emissions, and labor practices |

| ISSB/SASB Standards | Financial risks and opportunities | Investors and capital markets | Assessing how supply chain risks affect cash flow and access to capital |

These frameworks work hand-in-hand with supply chain transparency measures, which are becoming increasingly critical.

Supply Chain Transparency and Traceability Requirements

Both GRI and ISSB standards now require comprehensive supply chain accountability, even when no direct contractual relationships exist. GRI standards focus on impacts "directly linked" to products through business relationships. For bag manufacturers, this means tracking every step – from raw material extraction to final assembly – and addressing labor practices at facilities outside their direct control.

The forthcoming GRI Textiles and Apparel Sector Standard underscores the complexity of this task. It highlights the sector’s fragmented supply chain and its associated risks:

"the sector’s complex and fragmented supply chain… is characterized by a range of negative impacts. Most widely documented are those related to labor and human rights in producing countries".

Traceability is a critical element of due diligence, helping companies identify, prevent, and mitigate risks across their value chains. Manufacturers must pinpoint areas of concern, such as regions with known labor issues or environmentally sensitive raw material sources. When supply chain data is incomplete, companies are expected to disclose what information is missing, explain why, and outline steps to address these gaps.

This level of transparency allows stakeholders to evaluate whether companies meet global standards for responsible business practices, including adherence to the UN Guiding Principles on Business and Human Rights.

Compliance Challenges for Bag Manufacturers

Navigating global reporting standards is no small feat for bag manufacturers, especially when dealing with intricate supply chains. From tracking materials to assessing environmental impacts and ensuring ethical labor practices, the hurdles are numerous and demand strategic approaches, which we’ll explore further in this discussion.

Traceability and Material Sourcing

One of the toughest tasks for manufacturers is keeping tabs on raw materials as they move through multiple supply chain tiers. This involves tracing impacts that are "directly linked" to their products, covering everything from raw material extraction sites to traders and processing facilities. For instance, in bag production, this might mean following leather all the way from the tannery back to the livestock farm, or synthetic fabrics from the factory to their petroleum origins.

The challenge is compounded by fragmented data management. When different departments rely on isolated spreadsheets, version control issues arise, making it difficult to consolidate information accurately. Manual tracking methods often fall short of meeting the stringent documentation standards required.

Adding to the complexity, manufacturers must juggle a patchwork of regional regulations. For example, the EU Green Deal and the UK Plastic Packaging Tax enforce different rules, such as requiring packaging to contain at least 30% recycled content. Implementing detailed frameworks like GRI is also resource-intensive, requiring both financial investment and specialized expertise.

Environmental Impact Reporting

Beyond tracking materials, reporting on environmental metrics introduces another layer of difficulty. Supply chains account for about 60% of global emissions, yet many organizations struggle to gather accurate data. In fact, only 45% report Scope 3 emissions, which encompass everything from material production to product use. Fragmented data systems further obscure these measurements, making precise reporting a challenge.

For bag manufacturers, Scope 3 emissions are particularly tricky to calculate. When supplier data isn’t accessible, they often have to rely on conversion factors or national averages, which are far less accurate. Regulatory standards like IFRS/SASB demand specific metrics for the apparel and accessories sector, such as the total amount of priority raw materials (like leather, cotton, and synthetics) purchased in metric tons and the percentage certified to third-party standards.

On top of that, balancing sustainability with product performance is a constant juggling act. While recycled or eco-friendly materials are appealing, they don’t always meet the durability or functionality requirements needed for high-quality bag production.

Social and Labor Compliance

Ensuring fair labor practices across the supply chain adds yet another layer of complexity. Manufacturers must address labor issues, such as child or forced labor, even when these occur at the raw material extraction stage and involve indirect suppliers with whom they have no direct contractual relationship. This becomes even harder when sourcing materials from regions with weak law enforcement or ongoing conflicts.

Verification efforts are often hindered by barriers to stakeholder engagement. Communicating with at-risk workers can be challenging due to language differences, cultural obstacles, or fear of retaliation. To promote transparency, the Apparel, Accessories & Footwear industry now requires manufacturers to disclose both Tier 1 suppliers and those beyond Tier 1.

Manufacturers also face tough decisions when balancing competing priorities. For example, they must weigh the environmental impact of building a new facility against the potential job opportunities it could create for local communities. These trade-offs underscore the complexity of maintaining compliance while addressing broader social and environmental goals.

sbb-itb-1e6451b

How to Comply with Sustainability Reporting Standards

Aligning with global sustainability reporting standards might seem complex, but it becomes much more manageable with a clear strategy. By laying a strong groundwork, leveraging digital tools, and involving key stakeholders early on, you can simplify the process significantly.

Start with GRI Core Option Reporting

En GRI Standards offer a structured starting point for sustainability reporting. Specifically, GRI 1: Foundation 2021 is the essential entry point for any organization embarking on this journey. This framework became mandatory for all reports published after January 1, 2023, and provides step-by-step guidance to help organizations meet reporting requirements effectively.

The process begins with a four-step materiality assessment:

- Understand your organization’s context.

- Identify key impacts.

- Assess the significance of those impacts.

- Prioritize the most critical ones.

For full compliance, organizations must meet nine specific requirements. These include reporting all disclosures outlined in GRI 2 (General Disclosures), maintaining a GRI content index, and formally notifying GRI about the report. If certain disclosures cannot be fulfilled – due to confidentiality issues or unavailable data – you must document valid reasons in your content index.

Use Digital Traceability Systems

Digital tools can take your compliance efforts to the next level. For instance, the GRI Digital Taxonomy, introduced on June 19, 2025, enables machine-readable disclosures, making reporting more efficient. These systems are especially helpful in ensuring compliance with principles like Accuracy and Verifiability. They distinguish between measured data and estimates while documenting the methods used for calculations.

Digital traceability systems also help convert estimates into precise, measurable data. By tracking materials from their source to the final product, these tools allow you to document environmental impacts and labor conditions with greater accuracy. This level of transparency is increasingly expected by both regulators and customers.

Work with Stakeholders and Conduct Impact Assessments

Technical compliance is only part of the equation – engaging with stakeholders ensures your reporting reflects real-world impacts. Involve a diverse group, including employees, suppliers, consumers, local communities, and investors, to gain a well-rounded understanding of your organization’s effects. If direct engagement isn’t feasible, consult with representatives, NGOs, or subject-matter experts to gather valuable insights.

It’s important to prioritize impact materiality over financial considerations. Significant environmental or human rights impacts must be addressed, even if they don’t directly affect your bottom line. These findings can later inform financial materiality assessments, but the primary focus should remain on actual impacts. The revised Universal Standards, effective in 2023, have introduced stricter requirements for reporting on human rights and due diligence, emphasizing the importance of addressing tangible consequences.

Implementation Tips for JUNYUAN BAGS

JUNYUAN BAGS brings 15 years of manufacturing expertise to the table, supported by six production lines capable of producing 250,000 pieces monthly. With certifications like BSCI, ISO 9001, REACH, and RoHS, the company is well-positioned to tackle compliance challenges and turn them into strategic advantages. Here are some practical ways JUNYUAN BAGS can integrate sustainability into every step of its production process.

Track Certifications and Standards Compliance

JUNYUAN BAGS’ BSCI-audited factory ensures adherence to social and labor compliance standards, aligning with GRI Universal Standards. Meanwhile, ISO 9001 certification underpins quality management and process consistency. These existing audit reports can serve as foundational data for GRI 2 reporting.

With the GRI Taxonomy, launched in June 2025, enabling machine-readable sustainability disclosures, consider upskilling your team. Enroll staff in the GRI Professional Certification Program or specialized courses on climate and nature reporting. This ensures your team stays ahead of evolving standards and maintains accurate, comprehensive reporting.

Make Custom Bag Production More Sustainable

Digital tools like 3D Tech Packs can help finalize designs without physical samples, cutting down on waste. Track and document these savings – how many samples are avoided and the materials conserved. This data can enrich GRI Topic Standards reporting on materials and waste.

Using RPET (Recycled Polyethylene Terephthalate) for custom backpacks highlights your commitment to eco-friendly materials. Formalize the tracking of sustainable materials in your supply chain. Record key metrics like the percentage of recycled content, reductions in virgin material use, and energy savings. With over 5,000 custom projects across 30 countries, you already have a wealth of data to analyze trends and demonstrate progress in adopting sustainable materials.

Use Bulk Order Audits for Better Reporting

With a minimum order quantity of 500 units and a monthly capacity of 200,000 to 250,000 pieces, JUNYUAN BAGS has ample data for impact reporting. By auditing bulk orders, you can provide clients with clear metrics on the environmental and social impact of their production runs, turning compliance into a competitive edge.

For each bulk order, ensure production meets BSCI and ISO 9001 standards, then share verified metrics with clients. Use REACH and RoHS compliance documentation to demonstrate chemical safety and environmental standards. These audit-approved metrics build trust and create a shared language of accountability with stakeholders.

"Quality is our core competitiveness. BSCI ISO9001 CE CPSIA OKEX-TEX." – JUNYUAN BAGS

Conclusion: Using Sustainability as a Business Advantage

Global reporting standards aren’t just about compliance – they’re powerful tools that can set industry leaders apart. Take manufacturers like JUNYUAN BAGS, for example. By adopting frameworks like GRI and ISSB, they gain not only operational clarity but also access to new markets, giving them a clear edge in a competitive landscape. With the sustainable packaging market expected to hit $423.56 billion by 2029, transparent reporting becomes a critical factor for tapping into this growth.

The financial benefits are equally compelling. With 75% of 30 major countries either enforcing or planning financial penalties for sustainability non-compliance, proactive reporting isn’t optional – it’s essential for managing risks. But it’s not just about avoiding fines. Strong sustainability disclosures can also open doors to better financing options, as investors increasingly rely on ESG criteria to evaluate manufacturers.

This connection between financial health and sustainability is emphasized by IFRS S1:

"An entity’s ability to generate cash flows over the short, medium and long term is inextricably linked to the interactions between the entity and its stakeholders, society, the economy and the natural environment." – IFRS S1

JUNYUAN BAGS already has a solid foundation with certifications like BSCI and ISO 9001, the use of RPET materials, and digital design tools. The next step is to implement systematic reporting that clearly highlights their impact. By tracking recycled material usage, documenting waste reduction through digital prototyping, and sharing verified metrics with clients, they can build trust and credibility in the marketplace.

Bringing these reporting practices into the fold aligns operational goals with financial strategies. Sustainability reporting isn’t just about meeting regulations – it’s a long-term investment in brand strength. It positions companies to set industry benchmarks, attract premium clients, and deliver lasting value to stakeholders. This approach ties back to the earlier discussion on how transparency in reporting enhances both efficiency and competitiveness.

Preguntas frecuentes

How do global sustainability reporting standards influence the bag manufacturing industry?

Global sustainability reporting standards, like the GRI 301 Materials Standard, push bag manufacturers to evaluate their production methods more thoughtfully. These standards call for transparency about raw material sources, efforts to reduce waste, and the adoption of energy-saving practices.

By following these guidelines, companies do more than just check a compliance box – they show a real dedication to reducing their environmental footprint. This might include choosing eco-friendly materials, cutting down on production waste, and setting measurable goals for ongoing improvement. For businesses such as JUNYUAN BAGS, embracing these practices ensures their custom-designed bags align with both customer demands and global sustainability expectations.

What challenges do bag manufacturers face when complying with global sustainability reporting standards?

Complying with global sustainability reporting standards like GRI is no small feat for bag manufacturers. It demands gathering and verifying a wide array of data – everything from company details and production sites to workforce figures, financial records, and product information. This process isn’t just detailed; it can also consume a significant amount of time and resources.

On top of that, working within the intricate GRI framework involves coordinating input from various stakeholders. This requires thoughtful planning and a level of expertise that many manufacturers may find challenging to achieve. Balancing these requirements while striving for transparency and staying on track with sustainability goals can add considerable pressure to their operations.

How do digital traceability systems help bag manufacturers comply with sustainability standards?

Digital traceability systems give bag manufacturers the ability to monitor and document detailed information about materials, production methods, energy use, and waste. By leveraging standards like the GS1 Global Traceability Standard, these systems produce precise, reliable data needed for sustainability reporting frameworks such as GRI.

This approach enables manufacturers to offer clear and verifiable disclosures about their environmental impact. It not only simplifies compliance with global reporting standards but also strengthens trust among customers and stakeholders.

Móvil/What's App/Wechat

Móvil/What's App/Wechat Correo electrónico

Correo electrónico AÑADE

AÑADE