Accelerated aging tests are critical for verifying the claims of biodegradable bags. These tests replicate years of wear and tear in a short period by using heat, UV light, and moisture. They help manufacturers ensure that their products break down properly in specific disposal environments like compost, soil, or landfills. The process follows a three-tier framework:

- Tier 1: Evaluates physical degradation (e.g., oxidation).

- Tier 2: Assesses biodegradation by microorganisms.

- Tier 3: Confirms the absence of harmful residues after breakdown.

Standards like ASTM D6954 guide these tests, ensuring materials degrade appropriately under controlled conditions. Manufacturers use this data to improve product performance, meet certifications, and validate biodegradability claims. For example, compost bags are tested for high heat and humidity, while landfill bags undergo anaerobic testing. This ensures that biodegradable bags are safe, effective, and aligned with their intended use.

How do you test if something really is compostable??

sbb-itb-1e6451b

How Biodegradable Bags Break Down Over Time

Biodegradable bags break down through a mix of chemical and physical processes triggered by environmental conditions. To understand how this happens, it’s important to examine how factors like heat, light, and moisture contribute to the degradation process. These elements work to weaken the polymer chains in the material, eventually causing it to fragment. Let’s take a closer look at how heat, UV light, and moisture each play a role in this breakdown.

Thermal Oxidation and Heat Exposure

Heat plays a major role in the breakdown of biodegradable polymers, and accelerated aging tests use high temperatures to simulate this process over time. When exposed to heat, chemical reactions within the polymers speed up, leading to faster degradation compared to normal conditions. Essentially, heat breaks the bonds in the polymer chains, creating free radicals. These free radicals then react with oxygen, forming hydroperoxides that further degrade the material by breaking the chains into smaller fragments.

The way a polymer reacts to heat depends on its type. For instance, polypropylene becomes brittle soon after degradation begins, while polyethylene tends to soften and weaken before eventually becoming brittle. Heat also reduces the "induction period", which is the phase during which antioxidants and stabilizers protect the material from rapid breakdown.

Different environments expose biodegradable bags to varying temperatures, which directly impacts how quickly they degrade. For example, industrial composting facilities can reach temperatures between 86°F and 149°F (30°C to 65°C), while soil environments typically stay cooler, ranging from 68°F to 86°F (20°C to 30°C). This explains why a bag designed for industrial composting might not break down as effectively in a backyard compost pile.

Photo-Oxidation and UV Light Exposure

UV light, especially from sunlight, is another powerful force that degrades biodegradable materials. Accelerated aging tests often replicate UV exposure to study this effect. UV rays are absorbed by specific parts of the polymer, such as pigments, catalyst residues, or double bonds, causing chemical bonds to break and releasing free radicals that drive the degradation process . As Elias H. Arias-Nava from Instituto Tecnologico Autonomo de Mexico explains:

Exposure of polymers to UV light irradiation leads to main chain scission causing mechanical deterioration and breaking into small pieces; this consequently allows oxygen and microorganism to degrade the polymer.

The impact of UV exposure can be dramatic. For example, high-density polyethylene (HDPE) can lose up to 80% of its strength after just 2,000 hours of UV exposure. Polylactic acid (PLA), another biodegradable material, experiences a 12% reduction in elasticity after the same amount of weathering. When UV exposure is combined with water spray cycles, simulating rain, the degradation accelerates even further. Flexural strength can drop by 52%, while tensile strength decreases by 34%.

Moisture, Hydrolysis, and Humidity Effects

Moisture is another key factor in the breakdown of biodegradable bags. Accelerated aging tests often include moisture exposure to study hydrolysis, a process where water molecules break the chemical bonds in the polymer chains. Polymers containing amide, ester, or urea groups are particularly vulnerable to hydrolysis .

Humidity levels vary widely depending on the disposal environment. Composting conditions typically have moisture levels between 45% and 70%, while soil environments range from 15% to 40%. This difference explains why biodegradable bags degrade faster in humid conditions or wet environments.

The most rapid degradation occurs when multiple factors, like heat, UV light, and moisture, act together. Mariaenrica Frigione, a professor at the University of Salento, highlights this phenomenon:

Simultaneous exposure to multiple environmental agents creates a synergistic effect, accelerating degradation.

For example, a bag exposed to both UV light and high temperatures will break down much faster than one exposed to just one of these factors. Accelerated aging tests aim to replicate these combined conditions in controlled lab settings to better understand how biodegradable materials behave in real-world scenarios.

Common Accelerated Aging Testing Methods

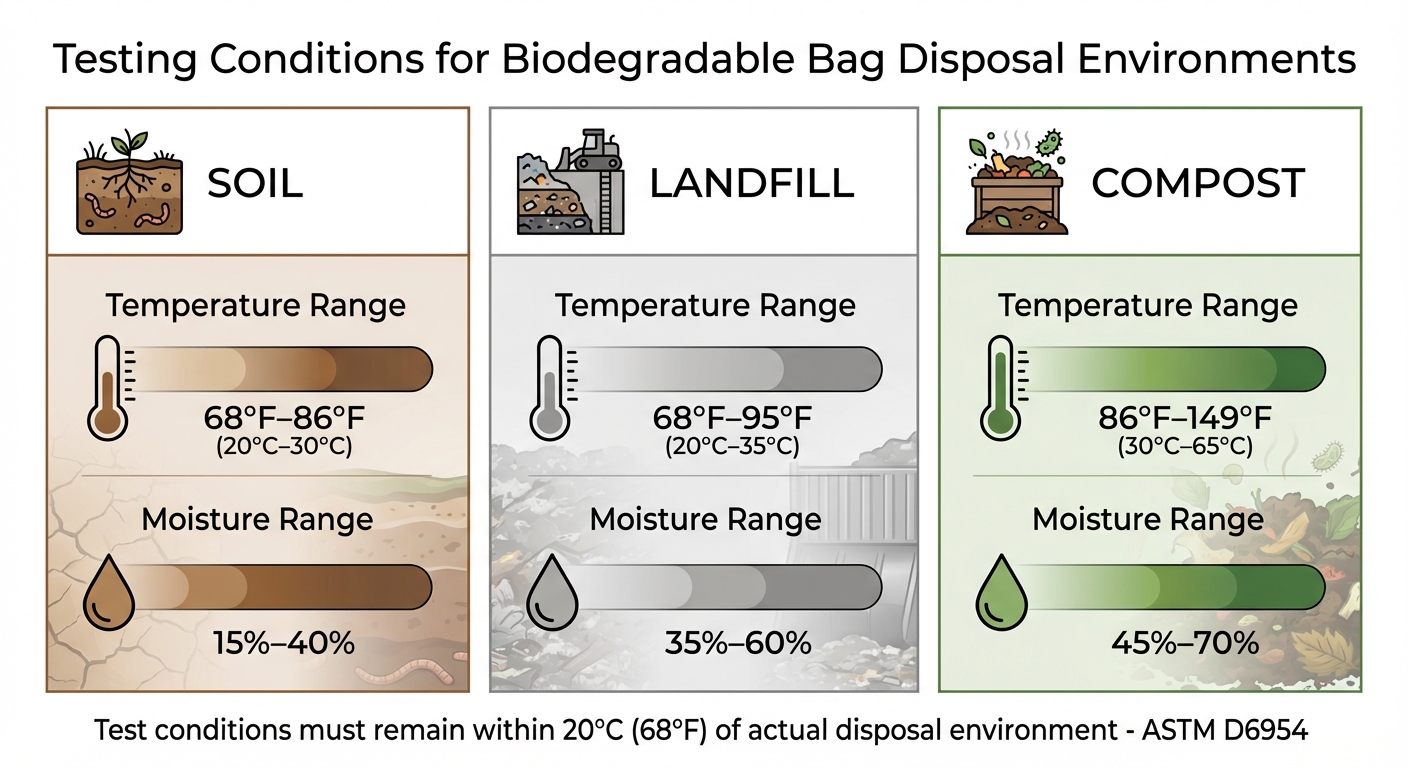

Biodegradable Bag Testing Environments: Temperature and Moisture Ranges

Now that we’ve covered how biodegradable bags break down, let’s dive into the testing methods used to simulate these conditions. These tests compress years of wear and tear into just weeks or months, giving manufacturers critical insights into how their materials hold up over time. Most follow a tiered framework outlined in ASTM D6954, focusing on how materials react to specific stressors like heat, light, and moisture. This approach builds on our earlier discussion about the environmental factors that drive degradation.

Thermal Accelerated Aging

Heat plays a major role in breaking down polymers, and thermal accelerated aging tests use high temperatures to mimic long-term storage and disposal conditions. According to the Arrhenius equation, a 10°C increase in temperature typically doubles the reaction rate. By exposing materials to elevated temperatures for shorter periods, researchers can predict how a biodegradable bag will perform over months or years.

Accuracy in thermal testing depends on selecting the right temperature range. ASTM International highlights that test temperatures should remain within 20°C of the actual disposal environment to avoid triggering unrealistic degradation mechanisms. For instance, a bag meant for soil disposal (68°F–86°F or 20°C–30°C) shouldn’t be tested above 122°F (50°C). Similarly, bags designed for industrial composting, where temperatures range from 86°F–149°F (30°C–65°C), require higher test temperatures.

The type of oven used also matters. Gravity-convection ovens work best for thin films (up to 0.25 mm thick), while forced-ventilation ovens are better suited for thicker materials, ensuring even heat distribution. During testing, manufacturers monitor tensile strength and elongation, defining embrittlement as a 75% drop in specimens’ elongation to 5% or less.

This thermal testing lays the groundwork for understanding how UV exposure further accelerates material breakdown.

UV and Photo-Oxidative Aging

UV radiation is another major factor in material degradation. UV and photo-oxidative aging tests replicate the effects of sunlight in a controlled lab environment. The challenge lies in accurately reproducing natural sunlight.

Filtered xenon arc lamps are commonly used because they mimic the solar spectrum, especially in the 290–400 nm range. This range is important because Earth’s ozone layer blocks UVC radiation (200–290 nm) and most UVB (290–320 nm), leaving UVA radiation (320–400 nm) as the primary culprit for degrading plastics. For general outdoor durability tests, UV-A fluorescent lamps with a peak emission at 340 nm and an irradiance of 0.76 W/m² are effective at simulating the intensity of sunlight at noon during summer.

Studies on biodegradable PLA/PBAT blends reveal that UV exposure leads to visible surface damage – like cracks and holes – and chemical changes, such as a shift in bonds from C-H/C-C to carbon-oxygen functional groups (C-O/C=O). However, as ASTM International points out:

The results of laboratory exposure cannot be directly extrapolated to estimate absolute rate of deterioration by the environment because the acceleration factor is material dependent and can be significantly different for each material.

While UV testing offers valuable comparative data, it’s important not to rely solely on lab results for predicting real-world performance.

Combining UV exposure with other environmental factors often leads to even faster degradation.

Combined Environment Testing

To better replicate real-world conditions, combined environment testing incorporates temperature, humidity, and UV exposure. This approach acknowledges that biodegradable bags are rarely exposed to just one stressor at a time. Instead, they face a complex mix of factors that work together to speed up degradation.

Humidity levels are adjusted to match specific disposal scenarios. The table below highlights the temperature and moisture ranges used for different environments:

| Disposal Environment | Temperature Range | Moisture Range |

|---|---|---|

| Soil | 68°F–86°F (20°C–30°C) | 15%–40% |

| Landfill | 68°F–95°F (20°C–35°C) | 35%–60% |

| Compost | 86°F–149°F (30°C–65°C) | 45%–70% |

These tests often cycle through different conditions, such as alternating UV exposure with water spray to mimic rain or combining high temperatures with elevated humidity to replicate composting environments.

When multiple stressors are combined, the degradation process accelerates significantly. For example, a biodegradable bag exposed to both UV light and high humidity will break down much faster than one exposed to UV alone. This type of testing provides a more realistic picture of how a bag will perform in actual disposal scenarios – whether it ends up in a backyard compost pile, a landfill, or agricultural soil.

These methods form the backbone of industry standards and certifications that verify biodegradable claims. By simulating real-world conditions, manufacturers can ensure their products meet expectations for performance and sustainability.

Standards and Certifications for Biodegradable Bag Aging Tests

Accelerated aging tests are guided by internationally recognized standards, ensuring uniformity and dependability across the industry. These standards provide manufacturers with precise testing benchmarks for biodegradable materials, helping them substantiate claims about their products’ environmental impact.

ASTM and ISO Standards

ASTM D6954-18 lays out a three-part approach (priced at $86.00):

- Tier 1: Uses thermal and photo-oxidation methods for accelerated aging.

- Tier 2: Measures biodegradation rates.

- Tier 3: Evaluates ecological impact.

This standard applies to polymers designed to degrade within 24 months and requires test temperatures to remain within 20°C (68°F) of actual disposal conditions.

For products marketed as compostable, compliance with ASTM D6400-21 ($77.00) or its global counterpart, ISO 17088, is mandatory. These standards ensure materials biodegrade at rates comparable to other compostable items in municipal or industrial aerobic facilities. This helps maintain operational efficiency in composting systems, avoiding visible plastic fragments during intermediate stages.

ASTM D7444-18a ($72.00) focuses on heat and humidity aging for oxidatively degradable plastics. It defines the embrittlement point as when 75% of samples achieve 5% or less tensile elongation at break. While this standard allows for material comparison, it’s intended for ranking purposes rather than predicting exact degradation timelines.

For biodegradable bags meant for landfill disposal, ASTM D7475-20 ($72.00) simulates the transition from aerobic to anaerobic conditions over a 30-day period. This standard measures the conversion of carbon into CO₂ and methane, offering a realistic view of landfill degradation. Notably, ASTM D5526-18, which previously addressed anaerobic biodegradation in landfills, was withdrawn in July 2025 without a replacement.

Here’s a summary of the key standards, their focus areas, pricing, and ISO equivalents:

| Standard | Focus Area | Precio | ISO Equivalent |

|---|---|---|---|

| ASTM D6954 | Oxidation & Biodegradation Framework | $86.00 | None |

| ASTM D6400 | Compostable Labeling Requirements | $77.00 | ISO 17088 |

| ASTM D7444 | Heat & Humidity Aging | $72.00 | None |

| ASTM D7475 | Bioreactor Landfill Simulation | $72.00 | None |

These standards form the foundation for certification processes that help verify biodegradable claims.

Certification Requirements for Biodegradable Bags

Accelerated aging tests play a key role in meeting the stringent requirements for certification. Certification ensures that manufacturers’ claims align with established standards. For example, to label a bag as compostable in aerobic facilities, compliance with ASTM D6400 or ISO 17088 must be demonstrated.

If testing under ASTM D7475 is limited to Tier 1, products can only be described as having altered physical properties rather than being fully biodegradable. Likewise, accelerated aging test results alone cannot justify unqualified biodegradability claims. Certification reports must detail the exact percentage of carbon converted to gas during the test.

Test conditions must also reflect real-world disposal environments. At least one test temperature must fall within 20°C (68°F) of the disposal setting, with humidity ranges mirroring specific conditions:

- Soil: 15%–40%

- Landfills: 35%–60%

- Compost: 45%–70%.

Designing Accelerated Aging Programs for Biodegradable Bags

Choosing the Right Test Methods

When designing a testing program for biodegradable bags, it’s essential to mimic the conditions these bags will face during disposal. For instance, soil environments typically range from 20–30°C, landfills from 20–35°C, and compost settings from 30–65°C. These temperature ranges, along with the material’s properties, should guide your approach.

Pay attention to the material’s physical limits – temperatures must stay below its glass transition temperature or melting point. Pushing beyond these thresholds can lead to unrealistic degradation outcomes, such as delamination or softening, which wouldn’t naturally occur. A solid testing protocol should cover three main areas: abiotic degradation, biodegradation rates, and ecological impact.

Moisture levels should also match the disposal environment. For example, soil typically has 15–40% moisture, landfills 35–60%, and compost 45–70%. If the bags are designed for outdoor use, include UV exposure cycles (290–400 nm) to replicate summer sunlight. The type of oven used for testing depends on the material’s thickness – gravity-convection ovens work for films thinner than 0.25 mm, while thicker materials may require forced-ventilation ovens.

These carefully tailored test conditions lay the groundwork for meaningful performance evaluations.

Interpreting Test Results

Once the right methods are in place, the focus shifts to analyzing the results. Testing should aim to compare materials rather than predict exact degradation timelines. As noted in ASTM D6954-18:

The results of laboratory exposure cannot be directly extrapolated to estimate absolute rate of deterioration by the environment because the acceleration factor is material dependent.

Since acceleration factors vary depending on the material, it’s crucial to use this context to benchmark your findings. Including a control sample with known outdoor performance can help validate test results.

Instead of providing a generic "biodegradable" label, report raw data with detailed conversion metrics. For instance, monitoring molecular weight reduction during Tier 1 tests can indicate when a material has broken down into biodegradable residues. For oxidatively degradable plastics, embrittlement can be defined when 75% of specimens show 5% or less tensile elongation at break.

Temperature plays a key role in these tests. A 10°C (18°F) increase roughly doubles the reaction rate. Under standard conditions (55°C or 131°F), 40 days in a test chamber can simulate about one year of real-world storage. However, avoid exceeding 60°C (140°F), as higher temperatures can prematurely damage the material instead of accurately replicating natural aging.

Applications for Customizable Bags by JUNYUAN BAGS

Insights from these testing methods directly shape material selection and product design at JUNYUAN BAGS. The company uses accelerated aging protocols to ensure their customizable bags – such as sports bags, travel bags, and eco-friendly options – meet both durability and biodegradability expectations. For outdoor-focused bags like golf or pickleball equipment carriers, UV testing is conducted to confirm resilience against prolonged sun exposure. This ensures that biodegradable materials maintain their structural integrity throughout their intended lifespan.

JUNYUAN BAGS also incorporates disposal environment considerations into its custom design process. For example, when creating biodegradable bolsas de pañales or pet bags, the company evaluates whether the materials are likely to end up in municipal composting facilities or landfills. This helps them choose polymers that align with realistic end-of-life scenarios, while still delivering the durability customers expect. By combining thoughtful material selection with rigorous testing, JUNYUAN BAGS ensures their products meet both environmental and performance standards.

Conclusión

Accelerated aging tests play a crucial role in ensuring the quality and environmental compatibility of biodegradable bags. By employing a structured, three-tiered testing process – spanning abiotic degradation (Tier 1), biodegradation (Tier 2), and ecological impact assessment (Tier 3) – manufacturers can confirm that their products break down completely without leaving harmful residues in soil, compost, or landfills. This approach guarantees that bags remain durable during use but degrade appropriately after disposal.

These tests offer more than just compliance with environmental standards. They provide a practical and efficient way to evaluate different material formulations, enabling manufacturers to assess polymer performance based on factors like tensile strength loss, molecular weight reduction, and embrittlement. This systematic method not only validates material performance but also lays the groundwork for industry certifications.

"This guide is a sequential assembly of extant but unconnected standard tests and practices for the oxidation and biodegradation of plastics, which will permit the comparison and ranking of the overall rate of environmental degradation." – ASTM D6954-18

JUNYUAN BAGS integrates accelerated aging data into its product development process to enhance both durability and environmental safety. These testing protocols shape decisions about materials and design, ensuring products meet their intended disposal requirements while maintaining high performance. For instance, sports bags are designed to endure UV exposure, while bolsas de pañales are tailored for composting environments. Additionally, these tests confirm that degradation byproducts are safe and non-toxic, addressing key safety concerns.

Preguntas frecuentes

What factors influence how biodegradable bags break down?

The decomposition of biodegradable bags hinges on several important factors: temperature, humidity, and exposure duration. Surrounding environmental conditions, like whether oxygen is present or if the setting is anaerobic, heavily influence the process. Another critical element is the microbial activity in the area, as microorganisms play a key role in breaking down materials. Additionally, the bag’s material makeup – such as the type of polymer used and any added substances like antioxidants – impacts both the speed and efficiency of degradation. Together, these elements shape how effectively and quickly the bag breaks down.

What are accelerated aging tests, and how do they confirm the biodegradability of bags in different environments?

Accelerated aging tests mimic conditions like heat, humidity, oxygen levels, and microbial activity to see how biodegradable bags break down in various settings – soil, compost, landfills, or water. These tests use carefully controlled methods to recreate these environments and track key indicators such as material breakdown, carbon dioxide emissions, and weight loss.

The data gathered from these tests helps manufacturers verify that the bags will decompose as expected and meet biodegradability standards for their intended use. This ensures the materials are both environmentally safe and functional in real-world scenarios.

Why is it important to use standards like ASTM D6954 for testing biodegradable bags?

Standards like ASTM D6954 provide a reliable framework for assessing how biodegradable bags break down in different settings – whether it’s soil, compost, landfills, or water. These tests are designed to measure how effectively materials degrade under specific conditions.

By adhering to this standardized method, manufacturers and researchers can evaluate and compare materials with accuracy. This ensures that products align with environmental goals and function as expected, fostering confidence among consumers and meeting regulatory requirements.

Móvil/What's App/Wechat

Móvil/What's App/Wechat Correo electrónico

Correo electrónico AÑADE

AÑADE