Extended Producer Responsibility (EPR) laws are reshaping how custom bag manufacturers operate. These regulations hold producers accountable for the entire lifecycle of their products, from production to disposal, placing financial and operational responsibility on companies rather than taxpayers. By late 2025, seven U.S. states had enacted EPR laws for packaging, with more expected to follow. Here’s what you need to know:

- Increased Costs: Manufacturers face 20%-40% higher packaging costs due to EPR fees, calculated by material weight and recyclability.

- Compliance Requirements: Companies must register with Producer Responsibility Organizations (PROs), track detailed material data, and meet strict reporting deadlines to avoid fines of up to $50,000 per day.

- Material Challenges: Using hard-to-recycle materials like LDPE and HDPE thin films leads to higher fees. States like California have banned recycling symbols on non-compliant products starting in 2026.

- Opportunities: Shifting to recyclable, reusable, or lightweight materials can reduce fees and attract eco-conscious customers.

EPR is challenging but also encourages manufacturers to rethink their designs, materials, and processes to meet new standards while staying competitive.

Extended Producer Responsibility Essentials: Navigating U.S. Regulations

Challenges Custom Bag Manufacturers Face Under EPR

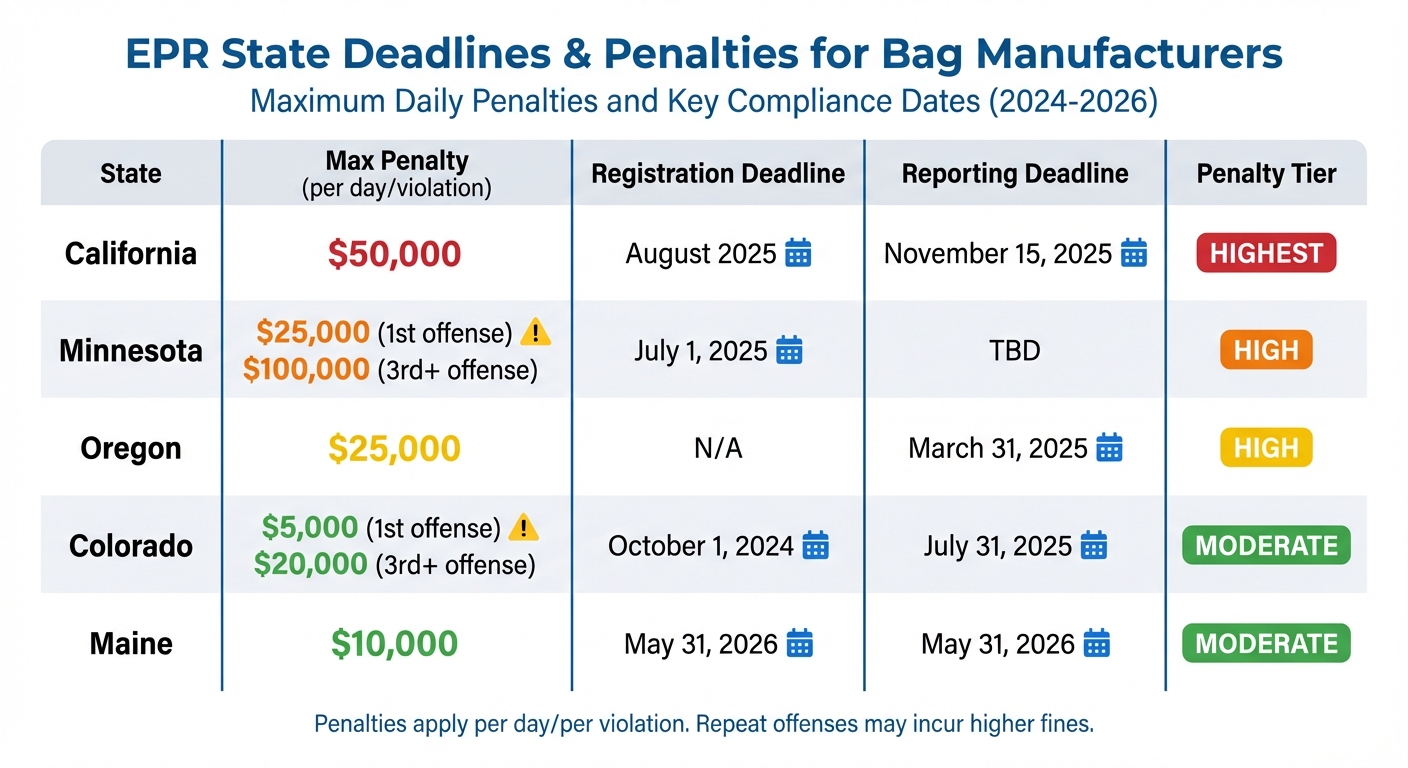

EPR State Deadlines and Penalties Comparison 2024-2026

EPR regulations bring a mix of administrative, material, and financial challenges for custom bag manufacturers. These requirements touch on everything from detailed paperwork to material selection, all while carrying significant financial implications. Understanding these hurdles is crucial for navigating compliance and finding effective ways to manage them.

Meeting Compliance and Reporting Requirements

Manufacturers are required to register with state-approved Producer Responsibility Organizations like the Circular Action Alliance (CAA), which handle compliance, recycling programs, and fee collection. On top of that, they must submit detailed annual reports, outlining the types of materials used – such as plastic, paper, or cardboard – the total weight and volume of materials sold in each state, and the post-consumer recycled (PCR) content of those materials.

The level of precision needed for these reports is significant. Companies must implement accurate tracking systems that record packaging weights, material types, and sales by jurisdiction. SKU-level and bill-of-materials (BOM) reporting have become critical to passing audits. Many businesses still rely on proxy data, which can lead to overpaying fees or falling short of compliance requirements.

Adding to the complexity, manufacturers must navigate a patchwork of state-specific rules, each with its own definitions, exemptions, and deadlines. Determining whether a company qualifies as an "obligated producer", identifying what counts as "covered material", and understanding potential exemptions requires careful analysis of both business operations and state regulations. Responsibility typically falls in a hierarchy: brand owners first, followed by brand or trademark licensees, and then U.S. importers if the first two are unavailable.

Even after resolving reporting challenges, manufacturers face rising material costs and strict design requirements that complicate production further.

Material Restrictions and Higher Production Costs

EPR fees are calculated based on the weight of packaging materials, meaning heavier materials result in higher costs. The type of material also plays a role – flexible plastics, for instance, incur higher fees than paper due to the greater investment needed for recycling infrastructure. For example, base fees for plastic film are about $0.63 per pound, compared to $0.30 per pound for paper.

"All affected packaging will be more expensive; it’s just a matter of how much more expensive." – Pregis

California’s EPR law alone requires producers to contribute $5 billion over 10 years – $500 million annually starting in 2027 – to combat plastic pollution.

Material restrictions add another layer of complexity. Many EPR laws ban substances like "forever chemicals" (PFAS) and certain plastics such as PVC or Expanded Polystyrene (EPS), forcing manufacturers to explore and test alternative materials. For instance, California prohibited the sale and distribution of EPS food service ware in January 2025 after producers failed to achieve a 25% recycling rate by the deadline. Custom bag manufacturers using specialized coatings or materials face similar challenges.

Design mandates further tighten production flexibility. States like California and Minnesota require single-use packaging to be 100% recyclable, compostable, or reusable by 2032. Additionally, California mandates a 25% reduction in single-use plastic packaging by 2032 compared to 2023 levels. Manufacturers are being pushed to redesign products for "lightweighting" and "right-sizing", which often involves costly retooling and extensive testing.

EPR Deadlines and Penalties

Missing EPR deadlines can lead to steep fines, ranging from $5,000 to $100,000 per day depending on the violation.

| State | Max Penalty (per day/violation) | Key Deadline |

|---|---|---|

| California | $50,000 | Registration: August 2025 / Reporting: Nov 15, 2025 |

| Colorado | $5,000 (1st), $20,000 (3rd+) | Registration: Oct 1, 2024 / Reporting: July 31, 2025 |

| Minnesota | $25,000 (1st), $100,000 (3rd+) | Registration: July 1, 2025 |

| Oregon | $25,000 | Reporting: March 31, 2025 |

| Maine | $10,000 | Registration & Reporting: May 31, 2026 |

On top of these penalties, non-compliant manufacturers may face higher base fees for using non-recyclable materials or failing to meet PCR content requirements. California’s SB 343 law also prohibits misleading recycling claims, requiring standardized labeling to confirm whether a product is recyclable or compostable in that jurisdiction. For instance, manufacturers selling poly mailers or thin-film bags in California must remove recyclability symbols by October 4, 2026, to avoid penalties.

These challenges demand immediate action. The regulatory environment is tough, and the financial consequences of non-compliance far outweigh the costs of investing in proper systems and materials.

How EPR Creates New Opportunities for Bag Manufacturers

EPR regulations are shaking things up in the bag manufacturing industry. While they might seem like a hassle at first glance, they’re actually creating new opportunities for forward-thinking companies. By adopting sustainable materials and focusing on circular design, manufacturers can not only reduce fees but also earn customer loyalty and even charge premium prices. Let’s break down how these shifts in materials, design, and partnerships are opening doors for innovation.

Using Recyclable and Biodegradable Materials

One of the key ways EPR programs encourage sustainability is through eco-modulation. This system adjusts fees based on the environmental impact of materials. Bags made with high post-consumer recycled (PCR) content or materials that are easy to recycle come with lower fees, while those made with hard-to-recycle materials face higher costs. This approach motivates manufacturers to prioritize PCR content and lighter designs, which can significantly cut costs. For example, Colorado’s draft eco-modulation schedule offers up to a 10% fee reduction for using PCR content or reusable systems. Additionally, since fees are weight-based, manufacturers are incentivized to "lightweight" their products by switching to flexible materials or trimming unnecessary layers, potentially reducing costs by as much as 40%.

"EPR does not need to be just a regulatory hurdle. Rather, it is a catalyst for packaging innovation and a movement to drive sustainability." – Packsize

The market is responding positively to these changes. A whopping 90% of consumers are more likely to support brands that use sustainable packaging, and over half actively seek out products with eco-friendly materials. Companies that prioritize sustainability see real rewards, with a 26.6% average price premium and potential revenue growth of 6% to 25% due to increased market share. This shift to sustainable materials also opens the door to fresh product designs, such as reusable bag systems, which we’ll explore next.

Creating Bags for Reuse and Recycling

Sustainable materials are just the beginning. Designing bags that can be reused or recycled is another way manufacturers can stand out in a crowded market. States like California and Minnesota are setting ambitious goals, requiring that all single-use packaging be recyclable, compostable, or reusable by 2032. Meanwhile, Washington’s Recycling Reform Act will provide $5 million annually starting in 2029 to help businesses create reusable or refillable packaging systems.

This isn’t just about meeting legal requirements; it’s about leading the industry. Over 150 global companies now back EPR policies as part of their sustainability efforts. Manufacturers who create reusable bags aligned with circular economy principles are becoming key partners for major brands. By moving away from the "take-make-waste" model and focusing on durability and multiple-use cycles, companies can climb higher in the value chain and unlock new business opportunities.

"Producers are the stakeholder who is best suited to implement positive changes at the end of the product lifecycle." – TOMRA

Working with Certified Manufacturers

Teaming up with certified manufacturers who understand EPR requirements can help companies navigate these changes with less risk. For instance, JUNYUAN BAGS offers materials and designs that comply with EPR standards, along with precise SKU-level data that ensures accurate reporting and avoids inflated fees.

This accuracy is critical. Many companies still rely on proxy data for EPR reporting, which can lead to higher fees. Manufacturers like JUNYUAN BAGS provide precise Bill of Materials (BOM) data, helping brands save money. They also handle tricky labeling laws. For example, California’s SB 343 has deemed certain thin-film plastics non-recyclable, requiring manufacturers to remove recycling symbols from non-compliant bags by October 2026.

JUNYUAN BAGS also offers custom designs using materials that meet EPR standards, such as high PCR content and PFAS-free options. Their certifications (BSCI, CE, RoHS, ISO9001) provide third-party proof that their products meet regulatory requirements across multiple states. This kind of partnership allows brands to focus on their core business while ensuring their bags – whether sports bags, travel bags, or specialty items – are compliant and sustainable, without sacrificing quality or design flexibility.

"The brands that move early will avoid last-minute scrambles, inflated fees, and reputational risk. Make EPR compliance a 2025 priority." – Saloni Doshi & Jessica Dowding, EcoEnclose

sbb-itb-1e6451b

Steps to Meet EPR Requirements

Navigating Extended Producer Responsibility (EPR) requirements becomes much easier when the process is broken into manageable steps. As of late 2025, seven states have enacted packaging EPR laws, with 12 more introducing legislation this year.

For manufacturers like JUNYUAN BAGS, getting ahead through early registration and precise data tracking not only simplifies compliance but also supports efforts toward more sustainable production. Here’s a practical guide to streamline your EPR compliance process.

Register with Producer Responsibility Organizations

Start by confirming your role as the "obligated producer." Typically, this applies to the brand owner of the packaged product. If your brand is not based in the U.S., the importer or distributor may bear this responsibility instead. Once this is clarified, register with a Producer Responsibility Organization (PRO). In most states with active EPR laws – California, Colorado, Oregon, Minnesota, and Maryland – the Circular Action Alliance (CAA) has been designated as the PRO.

The registration process is straightforward. Visit the PRO’s website, submit your company details (including subsidiary Tax IDs/EINs), and sign the Participant Producer Agreement (PPA). This grants you access to essential reporting tools and guidance. Importantly, there are no registration fees with the CAA. Registering early not only helps you avoid legal risks but also gives you ample time to prepare accurate data ahead of reporting deadlines.

Here’s a quick overview of state deadlines:

| State | Registration/Reporting Deadline | Key Penalty for Non-Compliance |

|---|---|---|

| California | Register by Sept 5; Report by Nov 15 | Up to $50,000/day/violation |

| Colorado | Register by July 1; Report by July 31 | Up to $5,000/day (first violation) |

| Oregon | Report by March 31 (Grace to April 30) | Up to $25,000/day/violation |

| Minnesota | Register by July 1 | Up to $25,000/day (first violation) |

Complete Verification and Submit Reports

Once registered, the next step is gathering accurate data. You’ll need to report details such as the material type, weight, and recyclability of all covered packaging introduced into state markets. This includes everything from primary packaging (e.g., the bag itself when sold as a product) to secondary packaging and shipping materials like mailers or boxes.

Accurate SKU-specific Bill of Materials (BOM) tracking is crucial. It prevents overestimating fees and ensures compliance. For example, Oregon’s estimated EPR fees range from $0.17 to $0.23 per pound of covered material. Relying on proxy data could result in significantly higher costs.

Each state has its own reporting schedule, so it’s essential to monitor state-specific portals. For instance, California’s portal opened on September 15, 2025, with data submissions due by November 15. Missing deadlines can lead to steep penalties. In Minnesota, repeated violations within five years can result in fines of up to $100,000 per day. Additionally, maintain detailed records for at least five years to support verification during audits.

Optimize Manufacturing Practices

EPR compliance isn’t just about reporting; it’s also an opportunity to refine your manufacturing practices. Reducing material use – known as lightweighting – can cut packaging weight by up to 40%, which lowers both shipping costs and EPR fees, as these are typically weight-based.

Switching to mono-material designs is another smart move. Multi-layer or composite materials are harder to recycle and often come with higher fees under eco-modulation schedules. Mono-material packaging, on the other hand, simplifies recycling and can qualify for lower fee tiers. For instance, Colorado’s draft eco-modulation schedule offers up to a 10% fee reduction for using high post-consumer recycled (PCR) content or introducing refill/reuse systems.

It’s also vital to eliminate banned substances like PFAS, PVC, and polystyrene from your products. This helps avoid regulatory bans and penalties. California, for example, mandates that 100% of covered materials must be recyclable or compostable by 2032. Automating data collection and implementing SKU-level tracking can further streamline reporting and reduce errors.

"As EPR regulations evolve, brands must not only adopt sustainable packaging practices, but also demonstrate clear, data-driven accountability." – Troy Rydman, Chief Information Security Officer, Packsize

Conclusion: Meeting Regulations While Moving Forward

Extended Producer Responsibility (EPR) is reshaping the landscape of custom bag manufacturing, compelling manufacturers to adapt or face steep penalties. In some key states, fines can climb as high as $50,000 per day for non-compliance, with repeat offenses leading to even harsher consequences. These stringent regulations challenge manufacturers but also present a chance to turn compliance into a powerful competitive edge.

While EPR brings its share of hurdles, it also opens doors for those willing to innovate. Manufacturers adopting sustainable practices early are discovering real market advantages. For example, companies shifting to eco-friendly production methods are experiencing notable growth in demand and customer loyalty. By redesigning bags with recyclable mono-materials, using post-consumer recycled (PCR) content, and employing lightweighting techniques, manufacturers can lower both EPR fees and production costs while meeting the rising demand for sustainable products.

"EPR does not need to be just a regulatory hurdle. Rather, it is a catalyst for packaging innovation and a movement to drive sustainability." – Packsize

For forward-thinking companies like JUNYUAN BAGS, compliance involves more than just meeting the bare minimum. It means registering with a Producer Responsibility Organization, accurately tracking material data, and ensuring banned substances are eliminated. Transparency plays a key role, with initiatives like sharing recyclability data, providing PCR certifications, and offering tailored packaging solutions. These efforts transform compliance from a regulatory obligation into a meaningful service that fosters long-term customer relationships.

Preguntas frecuentes

What steps can custom bag manufacturers take to lower EPR-related costs?

Manufacturers of custom bags can cut down on expenses tied to Extended Producer Responsibility (EPR) by embracing smarter production and shipping strategies. Start by reducing packaging waste – use lightweight, recyclable materials and ensure bag designs are simple to disassemble and recycle. Another effective approach is consolidating shipments, which not only lowers logistical costs but also reduces the overall environmental footprint.

Another cost-saving move is joining a producer responsibility organization (PRO). These organizations allow manufacturers to share compliance fees and simplify the process of adhering to EPR regulations. By taking these steps, companies can save money while promoting more sustainable business practices.

What happens if you don’t follow EPR regulations?

Failing to meet Extended Producer Responsibility (EPR) regulations can lead to serious repercussions. Companies could face administrative sanctions and hefty fines, with penalties reaching as high as $50,000 per day for failing to register, report, or pay the necessary EPR fees.

To steer clear of these costly penalties, businesses – especially those in industries like custom bag production – must stay up-to-date on EPR requirements and take the necessary steps to remain compliant.

What are the benefits of using recyclable materials in custom bag production?

Using recyclable materials in custom bag manufacturing comes with multiple benefits. For starters, it can cut down on material costs and overall weight, which may help reduce Extended Producer Responsibility (EPR) fees. Plus, opting for recyclable materials contributes to reducing landfill waste and supports eco-conscious practices, making it easier to hit sustainability targets.

By choosing recyclable options, manufacturers can improve their environmental footprint while keeping up with changing regulations. This practice not only benefits the planet but also caters to the increasing consumer preference for greener, more responsible products.

Móvil/What's App/Wechat

Móvil/What's App/Wechat Correo electrónico

Correo electrónico AÑADE

AÑADE