Smart manufacturing, also known as Industry 4.0, is transforming industries by integrating AI, machine learning, and the Industrial Internet of Things (IIoT) to improve production processes. While the potential for increased efficiency, reduced costs, and faster production is immense, implementing these technologies comes with challenges. Here are the five most common hurdles manufacturers face:

- High Upfront Costs: Investing in advanced sensors, robotics, and software systems can strain budgets, especially for small manufacturers.

- Cybersecurity Risks: Increased connectivity exposes systems to hacking, data breaches, and operational disruptions.

- Workforce Resistance and Skills Gap: Employees may resist new technologies due to job insecurity or lack of technical skills.

- Legacy System Integration: Older equipment often struggles to communicate with modern technologies, creating inefficiencies.

- Supply Chain Disruptions: Material shortages and inconsistent standards complicate production and logistics.

These challenges require manufacturers to adopt phased investments, strengthen cybersecurity, upskill workers, retrofit existing equipment, and standardize supply chain processes. Companies like JUNYUAN-TASCHEN have already demonstrated success by addressing these issues strategically, delivering faster production times and personalized products without compromising efficiency.

5 Smart Manufacturing Challenges: Key Statistics and Solutions

Challenge 1: High Upfront Investment Costs

Breaking Down the Cost Barriers

Smart manufacturing comes with a hefty price tag upfront. Setting up the necessary hardware and infrastructure – like advanced sensors, IIoT gateway devices, and automated factory equipment – creates the backbone of a modern production setup. For custom bag manufacturers, this often means investing in robotic systems specifically designed for tasks like cutting and assembling materials. On top of that, software platforms such as manufacturing execution systems (MES), cloud-based solutions, and AI-driven tools to manage custom orders require a significant financial commitment.

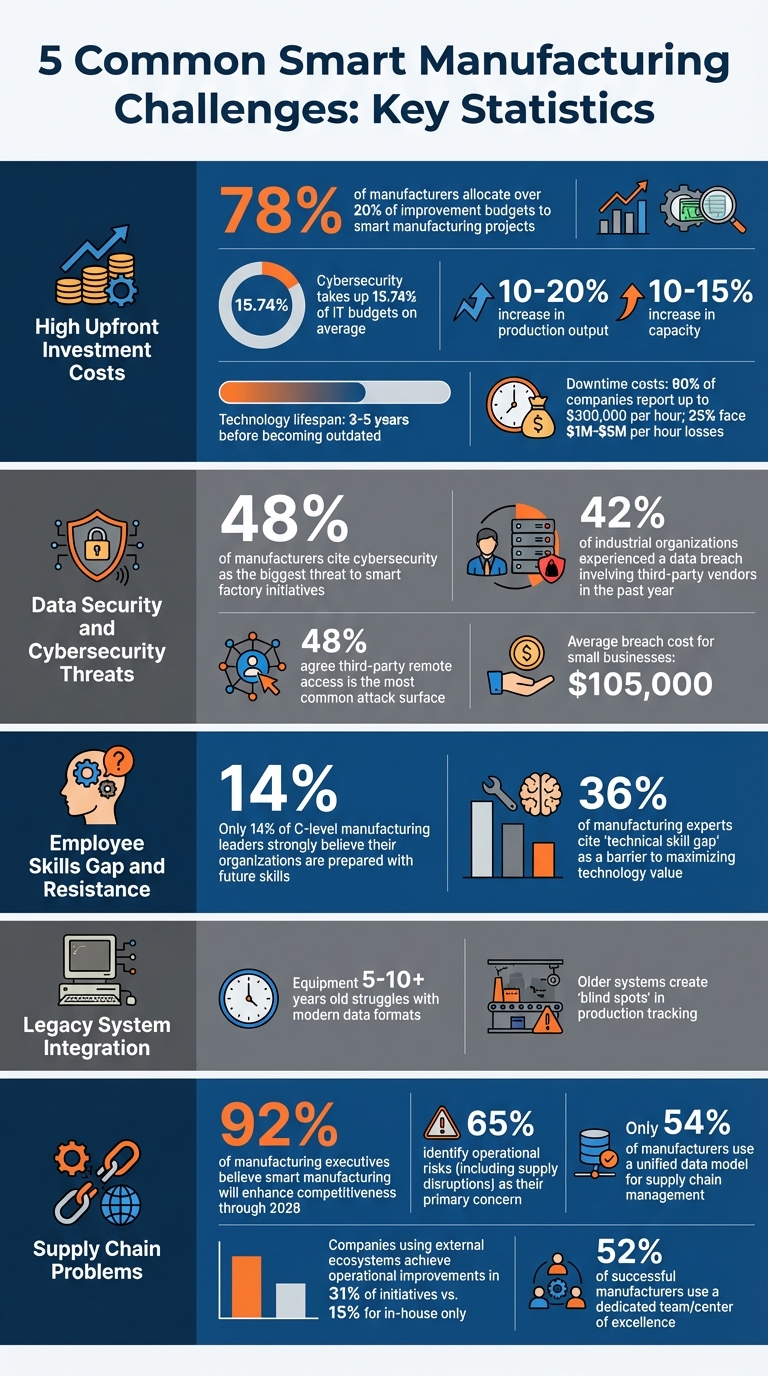

Currently, 78% of manufacturers allocate over 20% of their improvement budgets to smart manufacturing projects. Cybersecurity alone takes up an average of 15.74% of IT budgets to safeguard intellectual property and operational systems. Add to that the costs of hiring specialists, training staff, and consulting with experts, and the expenses keep climbing. Compounding the challenge, much of this technology has a limited lifespan, with components often becoming outdated in just three to five years, pushing manufacturers into regular reinvestment cycles. Despite these challenges, manufacturers can ease the financial strain by employing strategic and incremental investment plans.

Ways to Lower Initial Expenses

A practical way to tackle these costs is by adopting the "think big, start small, scale fast" approach. Conrad Leiva, VP of Ecosystem & Workforce at CESMII, explains it best:

A company, small or large, can use a strategy of phased investments to implement modular solutions and incrementally achieve benefits as the company incrementally achieves their vision.

This phased strategy not only reduces costs but also minimizes disruptions to operations. For instance, custom bag manufacturers like JUNYUAN BAGS (https://junyuanbags.com) can modernize their processes without breaking the bank. Retrofitting older equipment is a cost-effective option – adding affordable IIoT sensors to existing sewing machines can track metrics like vibration, temperature, and overall machine health. Another smart move is using open standards and APIs to avoid vendor lock-in, saving on future integration costs. Smaller manufacturers can also take advantage of no-cost readiness assessments offered by the MEP National Network, which provides access to over 1,400 technical advisors across the country.

The payoff for these efforts can be substantial. Smart manufacturing initiatives have been shown to boost production output by 10% to 20%, while increasing capacity by 10% to 15%. The stakes are high – 90% of companies report that an hour of downtime can cost them up to $300,000, and 25% face losses ranging from $1 million to $5 million per hour. By proving the value of smart manufacturing on a single production line first, manufacturers can manage cash flow effectively and build momentum for broader adoption. These strategies not only help custom bag makers overcome financial hurdles but also set the stage for long-term success in a competitive market.

Challenge 2: Data Security and Cybersecurity Threats

Common Security Vulnerabilities

The manufacturing sector has become a prime target for cyberattacks, and custom bag manufacturers are no exception. When production systems – like robotic cutting machines, inventory management software, and customer order databases – are connected to the Internet, each connection creates a potential entry point for hackers. Alarmingly, 48% of manufacturers cite cybersecurity as the biggest threat to their smart factory initiatives. Additionally, 42% of industrial organizations reported experiencing a data breach involving a third-party vendor in the past year.

Several factors contribute to these vulnerabilities. Many manufacturers continue to rely on legacy equipment paired with outdated computers running unsupported operating systems[17,9]. The blending of office IT systems with factory floor equipment has dissolved traditional security boundaries, increasing risk[17,18]. Third-party vendors often compound the problem by using risky practices like shared login credentials or poorly managed VPN connections – 48% of organizations agree that third-party remote access is now the most common attack surface. Even employees can unintentionally compromise security by introducing malware via USB drives or falling for phishing scams that mimic legitimate vendor emails[17,20].

Pat Toth from NIST highlights the potential consequences:

A breach in OT can interrupt the manufacturing process or impact product quality. It can cause companywide disruption in other departments like shipping and billing or endanger sensitive company information.

For custom bag manufacturers, such breaches could lead to losing proprietary designs, damaging customer trust, or incurring costs averaging $105,000 for small businesses. To mitigate these risks, manufacturers need to implement robust, multi-layered security measures.

Building Strong Security Defenses

Securing a smart manufacturing operation requires a combination of technological solutions and human vigilance. Start with annual risk assessments to identify critical systems and data – such as custom design files, customer records, and machine configurations. Implement multi-factor authentication (MFA) for all remote access points to ensure that compromised passwords alone can’t grant entry[17,19,9]. Employ application allowlisting to ensure only approved software runs on manufacturing workstations, effectively blocking malicious programs before they can execute[16,20].

A practical example comes from Oldcastle Infrastructure, Inc., which, in May 2025, replaced fragmented VPN systems with a centralized vendor privileged access management solution across 85 U.S. sites. This eliminated shared credentials and enabled real-time session logging, significantly strengthening their defenses. Custom bag manufacturers can adopt similar strategies to protect proprietary designs and sensitive customer data.

Additionally, manufacturers should maintain encrypted offline backups of critical production data to recover quickly from ransomware attacks[17,22]. Regularly monitoring network activity for unusual behavior and providing continuous employee training are also essential to defend against phishing and social engineering attacks. These steps create a more resilient security framework, reducing the risk of costly breaches.

Challenge 3: Employee Skills Gap and Pushback Against New Technology

Why Workers Resist and Lack Skills

Introducing new technologies in manufacturing often faces two major hurdles: a lack of technical skills and resistance from workers. Only 14% of C-level manufacturing leaders strongly believe their organizations are prepared with the skills needed for the future. Additionally, 36% of manufacturing experts cite a "technical skill gap" as a significant barrier to maximizing the value of technology investments.

Fear is a key driver behind this resistance. Workers worry that automation could replace their jobs or reduce their roles to repetitive tasks dictated by algorithms, stripping away judgment and autonomy. This fear of "deskilling" is especially pronounced in custom bag manufacturing, where skilled craftspeople take pride in their expertise with materials, stitching, and quality control. On top of this, tensions between operational technology (OT) and information technology (IT) teams over data access, security, and implementation timelines create additional friction. When tools like smart scheduling or productivity trackers are perceived as surveillance rather than support, stress levels rise, and employee turnover becomes a serious issue.

The technical knowledge gap only deepens these challenges. Few workers possess "digital dexterity", or the ability to bridge traditional manufacturing processes with modern digital tools. Stephen Laaper, Principal at Deloitte Consulting LLP, underscores the importance of addressing these human factors:

When the development is separated from the end users, you end up with a subpar product, subpar adoption… the human element is the critical ingredient.

To overcome both emotional and technical barriers, companies need a clear and well-executed training approach.

Building a Learning-Focused Workplace

Leading manufacturers address these challenges from the top down and the ground up. A key first step is identifying "change champions" – respected team members who can advocate for new systems and help resolve obstacles. Workers should also be involved early in the process. Conducting stay interviews to understand what tools they need to succeed and what might cause them to leave can provide valuable insights. As Celia Paulsen from NIST points out:

Change shouldn’t be imposed. Rather, it should instead be the outcome of a continuous discovery phase that empowers employees to test current processes and identify room for improvement.

Hands-on training and clear career growth opportunities are essential. Partnerships with local colleges and training centers, for example, have proven effective in integrating co-op programs and apprenticeships. Training Within Industry (TWI) programs can further streamline onboarding and help high-performing employees step into leadership roles.

Incentives also play a big part. Linking wage increases or certifications to mastery of smart manufacturing tools encourages participation. Flexible training formats – whether online, hybrid, or on-the-job – help accommodate workers’ schedules and personal responsibilities. The first 90 days are especially critical for new hires. Pairing them with experienced mentors who embody company values fosters confidence and long-term engagement. By treating employee training as an ongoing, integrated process rather than a series of one-off events, manufacturers can shift resistance into enthusiasm and bridge the skills gap that threatens their competitive edge. For instance, JUNYUAN BAGS invests consistently in training programs that merge traditional craftsmanship with advanced digital tools, ensuring their workforce remains skilled and adaptable.

Challenge 4: Connecting New Systems with Old Equipment

Why Old and New Systems Don’t Work Together

Manufacturers often face the challenge of running facilities that rely on a mix of older and newer technologies. The problem? These systems don’t always play nicely together. Equipment and platforms that are more than five to ten years old often can’t handle the data formats required by today’s digitized environments. Some older machines rely on proprietary interfaces or lack digital interfaces altogether, creating "blind spots" in production where real-time performance tracking becomes impossible.

Legacy systems not only struggle with compatibility but also come with fragile integrations that limit real-time data sharing. This can lead to vendor lock-in, making it harder to adapt to new technologies. As Celia Paulsen from NIST puts it:

The older a technology infrastructure is, the more difficult it is to make it compatible with a digitized manufacturing environment.

Older manufacturing setups are often too rigid to support the flexibility needed for robotic operations or cloud-based resource planning. These limitations call for practical solutions to bridge the gap between outdated and modern systems.

How to Connect Systems Smoothly

Overcoming these integration challenges doesn’t mean replacing all legacy equipment overnight. Instead, manufacturers can take a phased, modular approach. Retrofitting older machines with Industrial Internet of Things (IIoT) sensors and using open standards like MTConnect oder OPC UA can help integrate legacy equipment into modern analytical platforms. Middleware and edge gateway devices can also act as translators, bridging the gap by converting data from older systems into formats that newer platforms can understand.

Starting with small-scale pilot projects is another smart move. This allows manufacturers to test integrations on a limited scale before applying them across the entire production line. Not only does this reduce risks to ongoing operations, but it also provides valuable insights for improving the process. By treating integration as a continuous effort, manufacturers can ensure that older systems and modern technologies work together efficiently.

For example, custom bag manufacturers like JUNYUAN BAGS have successfully modernized their production lines using these modular strategies without disrupting daily operations.

sbb-itb-1e6451b

Challenge 5: Supply Chain Problems and Missing Standards

Common Supply Chain Obstacles

Supply chain disruptions can severely hinder the adoption of smart manufacturing. One of the most pressing issues is material shortages, which are especially problematic for industries like custom bag production that rely on precise deliveries of fabrics, zippers, and hardware. A delay from even one sub-supplier can halt the entire production process. While 92% of manufacturing executives believe that smart manufacturing will enhance competitiveness through 2028, 65% identify operational risks – including supply disruptions – as their primary concern. Customization adds another layer of complexity; smaller production batches and personalized orders introduce variability, leaving manufacturers more exposed to sudden changes in the supply chain.

Another major challenge is the lack of unified standards. Without consistent data models, manufacturers lose visibility into their supply chains, creating so-called "hidden factories". The gap between Information Technology (IT) and Operations Technology (OT) further exacerbates this issue, as real-time data often fails to reach production systems. Currently, only 54% of manufacturers use a unified data model for managing supply chains, which limits their ability to respond to disruptions effectively. These obstacles highlight the urgent need for proven frameworks and advanced analytics to stabilize supply chain operations.

Building Reliable and Consistent Processes

To address these challenges, manufacturers should adopt standardized frameworks that enhance system communication. Standards like ISA-95, ISO, MTConnect, and OPC can bridge the gap between legacy equipment and modern digital tools. As Yan Lu, Katherine C. Morris, and Simon P. Frechette from NIST emphasize:

Standards are fundamental 1) to facilitate the delivery of the right information at the right time, 2) to enable actions based on that information and 3) to reduce risk of technology adoption and development.

Leveraging AI-powered predictive analytics can help manufacturers anticipate material shortages before they become critical issues. Additionally, creating a comprehensive "Digital Thread" – a detailed digital record of a product’s lifecycle – improves traceability and strengthens resilience against disruptions. Diversifying supplier networks across regions also helps mitigate localized risks. Research shows that companies that tap into external ecosystems achieve operational improvements in 31% of their smart manufacturing initiatives, compared to just 15% for those relying solely on in-house resources.

Synchronizing factory operations is another key strategy for reducing supply chain disruptions. This involves coordinating labor, equipment, and materials in real time. Investments in active sensors and vision systems can provide the foundation for advanced analytics, enabling manufacturers to build more flexible and adaptive supply chains.

For example, custom bag manufacturers can use these approaches to streamline their operations and quickly adapt to shifting supply conditions. Companies like JUNYUAN BAGS (https://junyuanbags.com) are already applying such strategies to maintain consistent performance despite ongoing supply chain challenges.

FloridaMakes Webinar: The Path to a Smart Manufacturing Future

Schlussfolgerung

The challenges of smart manufacturing – investment costs, security risks, skills gaps, legacy integration, and supply chain issues – can feel daunting for custom bag makers. But with thoughtful planning, the potential rewards are immense. In fact, research shows that 92% of manufacturing executives believe smart manufacturing will be a key driver of competitiveness in the coming years.

For custom bag manufacturers, addressing these obstacles opens the door to improved efficiency and faster market response. For example, integrating legacy systems with smart equipment can drastically cut turnaround times. JUNYUAN BAGS (https://junyuanbags.com) has demonstrated this by delivering custom designs within 48 hours while maintaining high production capacity. Similarly, closing the skills gap through workforce upskilling equips teams to handle advanced tools like digital pattern-making software and automated machinery, minimizing errors when assembling intricate products like sports bags.

Success doesn’t happen overnight – it requires a step-by-step approach. Conrad Leiva, VP of Ecosystem & Workforce at CESMII, emphasizes the value of incremental investment:

A company, small or large, can use a strategy of phased investments to implement modular solutions and incrementally achieve benefits as the company incrementally achieves their vision.

Starting with a pilot program and establishing strong data governance can help avoid pitfalls like vendor lock-in while building momentum for broader implementation. Additionally, forming a dedicated team or center of excellence to oversee these efforts is a proven strategy – 52% of successful manufacturers already rely on this approach.

FAQs

What can small manufacturers do to manage the high upfront costs of adopting smart manufacturing?

Small manufacturers can tackle the challenge of high upfront costs by using a phased investment approach. This means starting small with impactful technologies like IIoT sensors or cloud-based platforms. These tools can deliver quick wins, such as cutting down on waste or speeding up production cycles. Once the benefits are clear, businesses can scale up gradually, spreading out the financial commitment instead of facing a hefty one-time expense.

Another smart move is to tap into federal and state incentives. Grants, tax credits, and low-interest loans are often available to encourage technology upgrades and energy-efficient practices. These programs can significantly ease the financial load.

Switching to subscription-based models is also a game-changer. Services like pay-as-you-go cloud platforms or equipment-as-a-service allow manufacturers to convert large capital expenses into predictable monthly payments, making budgeting much easier.

Collaboration can further lighten the financial burden. For instance, local businesses or industry groups can co-invest in shared resources. Take custom-bag makers like JUNYUAN BAGS – they could team up to share costs on automation tools like smart cutting tables. This not only reduces individual expenses but also boosts efficiency for everyone involved.

By blending these strategies, small manufacturers can embrace smart manufacturing while keeping their budgets under control.

How can businesses reduce cybersecurity risks in smart manufacturing?

Reducing cybersecurity risks in smart manufacturing calls for a proactive, multi-layered strategy. One key step is isolating operational technology (OT) systems from corporate IT networks using segmentation and firewalls. Pair this with a zero-trust model, where every user and device must be verified before gaining access. Regular firmware updates for equipment like sensors and IoT devices are essential to patch vulnerabilities, while monitoring tools can help spot unusual activity in real time.

It’s also critical to have a well-defined incident-response plan. This plan should clearly outline roles, communication protocols, and recovery procedures to minimize downtime in the event of a breach. Strengthening supply-chain security is another priority – vet vendors carefully, establish secure configuration standards, and require cybersecurity compliance from all partners. Additionally, ongoing employee training is vital for recognizing threats such as phishing and unsafe practices.

For a custom-bag manufacturer like JUNYUAN-TASCHEN, these measures might involve setting up secure networks for production equipment, enforcing multi-factor authentication on design tools, and scheduling regular updates for IoT-enabled inventory systems. By embedding cybersecurity into everyday operations, JUNYUAN BAGS can protect its designs, customer data, and production processes while continuing to enjoy the advantages of smart manufacturing.

How can manufacturers address the skills gap and reduce resistance to new technologies in smart manufacturing?

Manufacturers looking to bridge the skills gap and ease resistance to new technologies should prioritize a people-first approach. The first step? Develop a clear strategy that ties new tools directly to business goals. When employees see how these changes align with the company’s vision, it helps minimize uncertainty and builds trust.

Next, invest in practical, ongoing training. Combine hands-on workshops with opportunities for continuous learning. For instance, short sessions on operating IoT sensors or navigating data dashboards can empower employees without overwhelming them. Add mentorship programs and cross-functional teams into the mix to share real-world success stories and address any roadblocks.

Start small with low-risk pilot projects to showcase quick wins – like cutting production time by 5–10%. Highlight these victories to build momentum and gain employee support. To further encourage adoption, consider offering incentives such as skill-based bonuses or opportunities for career growth. By taking these steps, companies like JUNYUAN BAGS can turn workforce challenges into stepping stones for growth and progress.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD