Eco-friendly travel bags are transforming the luggage industry. With the global luggage market projected to reach $36.16 billion by 2032, consumers are prioritizing products made from recycled and plant-based materials. Brands are responding by using options like recycled polyester (rPET), nylon from fishing nets, and vegan leather made from cork or apple peels. These materials reduce waste, cut CO2 emissions, and offer durability for modern travelers.

Key highlights:

- Recycled materials (e.g., rPET): Repurpose plastic bottles and reduce emissions by up to 50%.

- Natural fibers (e.g., hemp, canvas): Biodegradable and durable with minimal resource use.

- Vegan leather: Made from cork, mushrooms, or apple peels for a lower ecological footprint.

- Durability focus: Modular designs and repair services extend product lifespan, minimizing waste.

- Sustainable practices: Carbon-neutral shipping, recyclable packaging, and ethical sourcing are becoming standard.

The takeaway: Choose durable, repairable bags made from recycled or natural materials to reduce waste and support eco-conscious practices. Certifications like GRS and GOTS ensure materials meet strict sustainability standards.

Sustainable Travel Accessories & Everyday Carry Gear | The Best Brands Making Eco-Friendly Products

sbb-itb-1e6451b

Main Materials Used in Eco-Friendly Travel Bags

Eco-friendly travel bags are now crafted using a mix of recycled, natural, and plant-based materials that reduce environmental impact while maintaining durability and functionality.

Recycled materials are a cornerstone of sustainable luggage design. Recycled polyester (rPET) is particularly popular, making up nearly 60% of bag fabrics. To put it into perspective, a single backpack made from rPET can repurpose over 25 plastic bottles, reducing CO₂ emissions by about 1.25 lbs compared to using virgin materials. Recycled nylon, sourced from discarded fishing nets and textile waste, is another durable option often used for heavy-duty bags like duffels. Hard-shell luggage also benefits from recycled materials such as polycarbonate and polypropylene, which are derived from industrial scraps and post-consumer items like yogurt cups. Some collections have gone even further, incorporating at least 60% bio-circular and recycled materials, such as shells made from recycled cooking oil collected from restaurants. While recycled synthetics dominate the market, natural fibers provide an excellent biodegradable alternative.

Natural fibers stand out for their ability to break down much faster than synthetic materials, offering a more environmentally friendly lifecycle. Hemp is a prime example – it requires minimal water, no pesticides, and yields 250% more fiber per acre than cotton. Beyond its sustainability, hemp is naturally antibacterial, UV-resistant, and develops a beautiful patina over time. Canvas, made from cotton, hemp, or linen, is another durable option, prized for its tight weave and thick yarns that provide excellent tear resistance. Many brands now blend natural fibers with recycled synthetics to enhance waterproofing and overall strength while maintaining eco-friendly credentials. These materials not only reduce waste but also extend the lifespan of the products, aligning with a sustainable lifecycle approach.

In addition to recycled and natural fibers, vegan leather alternatives are gaining traction as replacements for traditional animal hides. Materials like cork, mushroom, and apple peel are being used to create vegan leather that closely resembles the look and feel of real leather but with a significantly lower environmental footprint. Banana fiber is another innovative option, offering resistance to water, fire, and tears while boasting a smaller carbon footprint.

When choosing umweltfreundliche Taschen, it’s important to check for certifications like the Global Recycled Standard (GRS) and the Global Organic Textile Standard (GOTS). These certifications ensure that sustainability claims apply to the entire bag, not just a small component like the lining. Ultimately, the greenest option is a durable bag designed to last for years, as longevity dramatically reduces the need for replacements and further resource consumption.

Benefits and Limitations of Eco-Friendly Materials

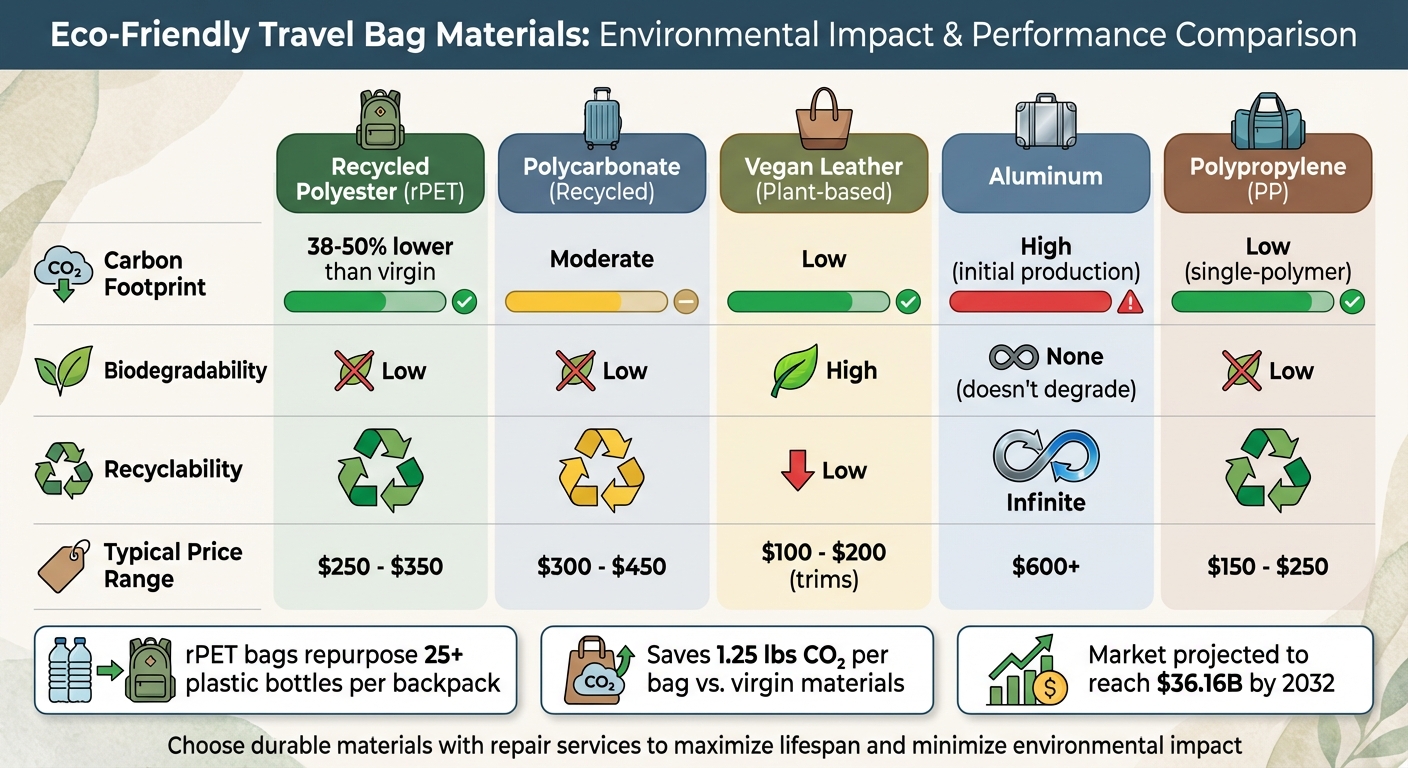

Eco-Friendly Travel Bag Materials Comparison: Carbon Footprint, Durability and Cost

Durability and Performance

Eco-friendly materials have made impressive strides in matching – or even surpassing – the durability and performance of traditional luggage fabrics. Take recycled polyester as an example. Advanced versions like ECOPAK™ EPX offer a waterproof rating of 200+ PSI and absorb 80% less moisture compared to traditional nylon laminates. This means your belongings stay dry without relying on coatings that degrade over time. Plus, it’s tough – heavy-duty versions can withstand 500 abrasion cycles and boast a 26.7 lbs tear strength in the warp direction.

Hard-shell materials have seen similar advancements. Recycled polycarbonate, for instance, is designed to flex on impact and return to its original shape, avoiding cracks that are common with lower-quality plastics. For travelers looking for lightweight yet durable options, polypropylene composites like Tegris provide excellent impact resistance while being up to 54% lighter than aluminum. However, polypropylene has its limitations – it can become brittle in freezing temperatures and warp under extreme heat.

"Sustainability is not just a matter of using eco-friendly materials – it’s also about creating luggage that will last." – Nayan Ingle, Associate Content Writer, Coherent Market Insights

That said, not all eco-friendly materials are equally robust. For example, natural options like rattan may crack under heavy use, while ABS plastic – commonly found in budget-friendly eco-lines – is lightweight but less resistant to impacts compared to premium polycarbonate. Choosing the right material depends on your travel habits. Frequent flyers might want to opt for polycarbonate or high-denier recycled nylon (1000D+) to ensure their luggage lasts longer.

This brings us to the environmental trade-offs associated with these materials.

Environmental Impact Comparison

The real strength of eco-friendly materials lies in their reduced environmental impact. For example, recycled polyester generates 50% fewer CO2 emissions than nylon and 38% fewer than virgin polyester. A single Reiserucksack made from recycled materials can repurpose over 25 plastic bottles and save around 1.25 lbs of CO2. These small savings add up, especially in an industry projected to reach $36.16 billion by 2032.

| Material | Carbon Footprint | Biodegradability | Recyclability | Typical Price Range (USD) |

|---|---|---|---|---|

| Recycled Polyester (rPET) | 38-50% lower than virgin | Low | High | $250 – $350 |

| Polycarbonate (Recycled) | Moderate | Low | Moderate | $300 – $450 |

| Vegan Leather (Plant-based) | Low | High | Low | $100 – $200 (trims) |

| Aluminum | High (initial production) | None (doesn’t degrade) | Infinite | $600+ |

| Polypropylene (PP) | Low (single-polymer) | Low | High | $150 – $250 |

The balance between a material’s environmental cost during production and its longevity is key. Aluminum, for example, requires significant energy to produce, but its infinite recyclability and durability mean it may never need replacing. On the other hand, plant-based vegan leathers have low carbon footprints and biodegrade naturally, but they often require more care and maintenance compared to synthetic options. Ultimately, investing in a durable piece of luggage that can last for decades will always be a more sustainable choice than replacing cheaper options every few years.

Eco-Conscious Design and Manufacturing Methods

Sustainable design isn’t just about the materials – it’s about rethinking every step of production, from energy consumption to packaging.

Ethical Sourcing and Production

For brands committed to sustainability, transparency has become non-negotiable. Many verify ethical practices through facility inspections, third-party certifications like ISO 9001, ISO 14001und Fair Trade, or by allocating resources directly to workforce initiatives. For example, one manufacturer channels 1% of its production costs into Fair Trade workforce programs. Similarly, some brands have earned the PETA‑Approved Vegan logo, ensuring no animal-derived materials are used in their supply chains.

Durability and repairability have also taken center stage. Modular designs with replaceable components are cutting down on waste, while lifetime warranties on functional damages promote a "buy once, use for life" mindset.

Factories are also stepping up with eco-friendly upgrades. Advanced wastewater treatment systems, LED lighting, and solar panels have helped reduce energy consumption by as much as 80%. Even small adjustments matter – one company saved approximately 201 trees in 2020 by switching from printed brochures to digital formats.

These efforts extend naturally to packaging and shipping, where manufacturers are finding equally thoughtful solutions.

Carbon‑Neutral and Recyclable Packaging

Packaging and shipping are significant contributors to a product’s carbon footprint. Air freight, for instance, generates 47 times more greenhouse gas emissions per ton-mile compared to ocean freight. To address this, many manufacturers are opting for sea-based logistics, even if it means longer delivery times. In 2021, one company cut its carbon footprint by 644 tonnes of CO₂ (about 710 short tons) by switching to ocean shipping and investing in carbon offsets for reforestation and renewable energy projects.

Packaging waste is another big focus. Traditional plastics are being replaced with compostable or recyclable materials, such as seed-infused boxes and water-activated paper tape. Some companies have gone a step further by eliminating single-use plastics entirely, using plant-based PLA bags for accessories and reusable cotton dust bags for luggage.

To tackle unsold inventory, certain brands enforce a strict "No Incineration Policy", ensuring deadstock is either recycled or repurposed instead of burned. The ultimate aim? To ensure every step of the product’s journey – from production to delivery – leaves as small a footprint as possible.

JUNYUAN-TASCHEN: Advancing Eco-Friendly Travel Bag Manufacturing

With the luggage market projected to hit $36.16 billion by 2032, companies focusing on sustainability and craftsmanship are redefining the industry. JUNYUAN BAGS stands out with its dedication to both personalized designs and eco-conscious practices.

Custom Design Services for Eco-Friendly Bags

JUNYUAN BAGS offers a personalized approach to designing travel bags, catering to both individual travelers and businesses that value sustainability. Their customization options cover every detail – logos, sizes, materials, and patterns – allowing clients to choose eco-friendly materials like rPET (recycled polyethylene terephthalate) for soft luggage or recycled polycarbonate for hard-shell cases. In fact, each backpack created from their custom designs repurposes over 25 plastic bottles, showcasing their commitment to reducing waste.

To ensure durability, JUNYUAN BAGS incorporates premium components like YKK zippers and ECOPAK™ EPX fabric. ECOPAK™ EPX not only resists abrasion but also absorbs 80% less moisture compared to nylon, making the bags more resilient and long-lasting. The brand’s modular designs, featuring replaceable parts, further extend the lifespan of their products. This "buy once, use for life" approach aligns with their mission to minimize waste while delivering high-quality travel gear.

Certifications and Quality Standards

JUNYUAN BAGS goes beyond innovative designs by adhering to strict ethical and quality standards. The company holds BSCI (Business Social Compliance Initiative) and ISO9001 certifications, ensuring responsible manufacturing practices. BSCI certification guarantees fair wages, safe working conditions, and a supply chain free from child labor. Meanwhile, ISO9001 certification ensures consistent quality management throughout production.

The environmental impact of these practices is significant. For example, recycled polyester reduces CO₂ emissions by 50% compared to nylon and 38% compared to virgin polyester. By prioritizing materials with a smaller carbon footprint, JUNYUAN BAGS demonstrates that sustainability and durability can go hand in hand. Whether producing a single custom order or fulfilling a large business shipment, the company maintains rigorous standards for performance and responsibility through global partnerships and careful oversight.

Conclusion: The Future of Luggage with Eco-Friendly Materials

The luggage industry is shifting in a big way, with sustainable materials evolving from a niche option to a standard expectation. Manufacturers are showing that being environmentally conscious doesn’t have to come at the expense of quality or performance – these two priorities can go hand in hand when designing modern travel gear.

Looking ahead, the focus is on creating a fully circular system. This means going beyond recycled materials to embrace "closed-loop" processes, where old suitcases are collected, taken apart, and transformed into new ones. Imagine scanning a QR code on your bag to trace every material back to its source – this is the promise of Digital Product Passports. Add to that modular designs that let you replace a single wheel or handle instead of tossing the entire suitcase, and it’s clear the future of luggage is all about sustainability.

When shopping for luggage, prioritize durability and repairability over fleeting trends. Certifications like the Global Recycled Standard (GRS) or B Corp can help confirm a brand’s environmental claims. Also, check if the manufacturer provides replacement parts or repair services – these features can significantly extend your bag’s life. Choosing luggage made from recycled materials is a small but impactful step toward reducing waste.

The next wave of travel gear will feature materials you might not expect – think plastics made from used cooking oil, leather alternatives derived from mushrooms or apple peels, and nylon regenerated from discarded fishing nets. Pair these materials with carbon-neutral production methods and smart technology, and you’ve got luggage that’s not only cutting-edge but also kind to the planet. By opting for these innovations, you’re investing in a bag that’s built for modern travel while supporting a more sustainable future.

FAQs

How can I tell if a travel bag is truly sustainable?

When searching for a sustainable travel bag, start by examining the materials. Look for options made from recycled fabrics, biodegradable materials, or alternative leathers that are designed to have less impact on the environment. Certifications can also be a helpful clue – brands that are transparent about their eco-friendly practices often highlight these.

Another key factor is the bag’s durability and repairability. A well-made bag that lasts for years and can be repaired instead of replaced helps cut down on waste. A sustainable travel bag isn’t just about the materials; it’s about combining those with a thoughtful, long-lasting design that minimizes its overall footprint.

Which eco-friendly material is best for frequent travel?

For those who travel often, recycled PET (polyethylene terephthalate) stands out as an excellent eco-conscious choice. This material is crafted from recycled plastics, such as post-consumer bottles, and offers a durable and sturdy solution that can handle the wear and tear of regular use.

On the other hand, plant-based options like cork or mushroom leather, while biodegradable, tend to be less durable and are better suited for lighter, occasional travel. Recycled PET strikes a practical balance, delivering both sustainability and the resilience needed for frequent travelers.

What makes a bag more repairable and longer-lasting?

A bag’s ability to last and be repaired hinges on smart design and sturdy materials. Features such as easily replaceable parts, tough fabrics, and fewer vulnerable areas – like minimal linings or external stitches – make repairs simpler and more effective. Durable fabrics and modular hardware help avoid premature wear and tear. Bags built with repair and refurbishment in mind can be refreshed or upgraded over time, keeping them in use longer and cutting down on waste.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD