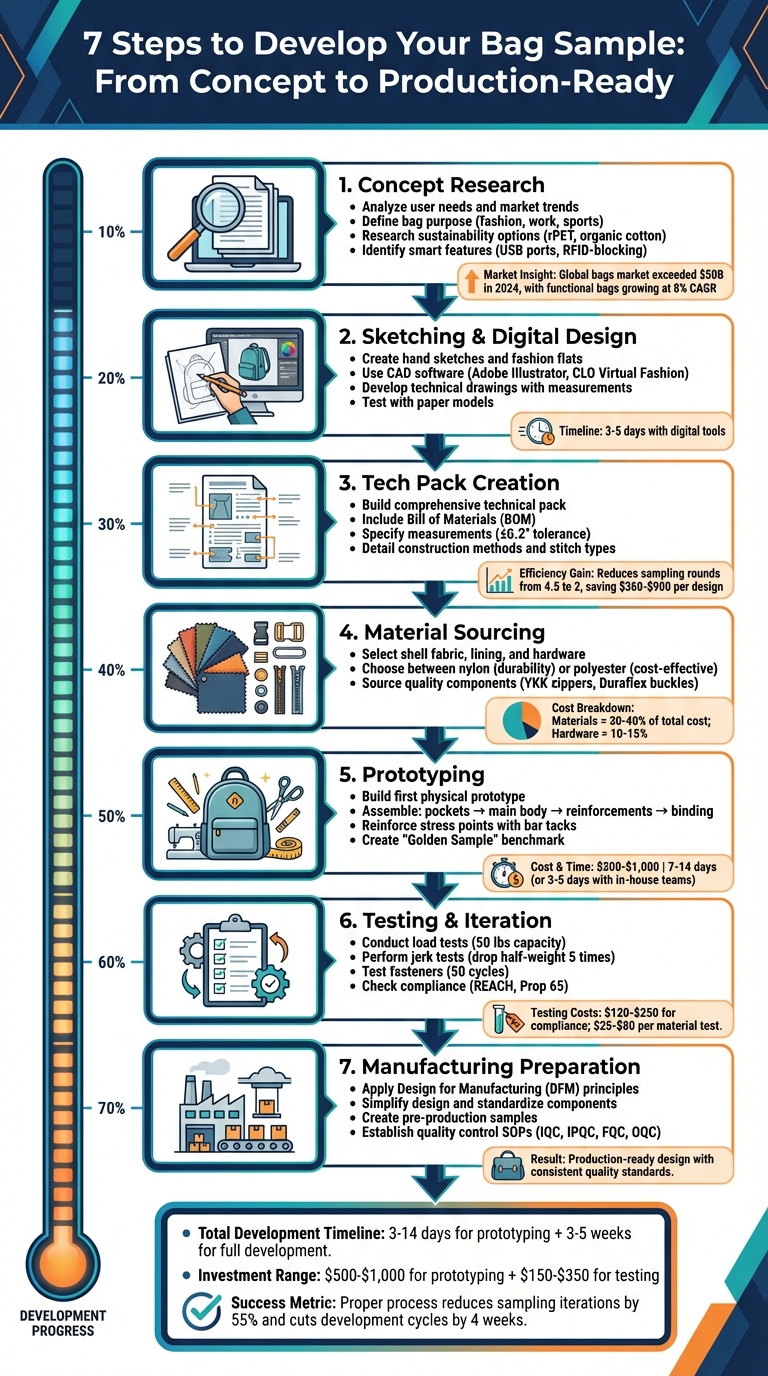

Creating a bag prototype involves turning a design concept into a functional sample ready for production. Here’s the process in a nutshell:

- Why It Matters: Prototyping helps identify flaws, test materials, and refine designs before mass production, saving time and money.

- Key Steps:

- Concept Research: Understand user needs and market trends, focusing on functionality, materials, and features like waterproofing or RFID-blocking.

- Sketching & Digital Design: Start with hand sketches, then use tools like Adobe Illustrator or 3D CAD software for precision.

- Tech Pack Creation: Develop a detailed document with measurements, materials, and assembly instructions.

- Material Sourcing: Choose durable, cost-effective fabrics and hardware, balancing quality with budget.

- Prototyping: Build and test the first sample, adjusting for durability and functionality.

- Testing & Iteration: Conduct load tests, stress tests, and compliance checks to refine the design.

- Manufacturing Preparation: Optimize the design for efficient production and finalize the "gold sample."

Costs & Timelines:

- Prototyping costs range from $500 to $1,000; timelines vary from 3-14 days depending on factory capabilities.

- Material and hardware choices impact both budget and durability.

Challenges:

- Common issues include communication errors, material delays, and sample-to-production inconsistencies. Detailed tech packs and clear communication help mitigate these risks.

This step-by-step guide ensures your bag design is functional, durable, and production-ready.

7-Step Bag Sample Development Process: From Concept to Production

How to Create a Sample and Prototype for Manufacturing | LaunchBoom

Step 1: Concept Development and Research

Every great bag begins with a solid understanding of what users need and the challenges that come with meeting those needs. Before diving into the design process, it’s essential to determine the bag’s purpose. Will it be a sleek fashion accessory, a practical work bag, or a specialized sports bag for activities like golf or tennis? In 2024, the global bags market surpassed $50 billion, with niche functional bags growing at an impressive 8% CAGR. This growth highlights a shift in consumer priorities – features like waterproofing, modular storage, and anti-theft designs are taking precedence over pure aesthetics.

Analyzing User Needs and Market Trends

Getting to know your target audience is all about pinpointing their specific challenges and desires. For instance, students often look for ergonomic designs with padded straps and compartments for laptops, while business travelers prioritize carry-on compatibility and TSA-approved locks. Outdoor enthusiasts? They’re after durability and water resistance. A quick dive into reviews on platforms like Amazon can uncover detailed user requests – ventilated compartments for sweaty gear, thoughtfully arranged pockets, or reflective accents for nighttime safety.

Market research also helps you steer clear of oversaturated categories. For example, one manufacturer used competitive analysis to identify a gap: while many yoga mat bags had ventilation holes, none included reflective details. Seeing an opportunity, they added reflective elements, creating a standout feature that resonated with their audience.

Sustainability is another growing trend. Materials like recycled PET (rPET), organic cotton, and plant-based alternatives are quickly becoming industry standards. On top of that, smart features – think USB charging ports, anti-theft zippers, and RFID-blocking compartments – are increasingly in demand. Customization is booming too, with a 15–20% annual growth rate, as smaller brands lean on private label manufacturing to offer personalized options.

At JUNYUAN-TASCHEN (https://junyuanbags.com), we make it a point to integrate these market insights into our designs right from the start. This ensures that every bag we create keeps up with the evolving needs of today’s consumers.

These insights lay the foundation for the next step: defining the technical features of the bag.

Defining Bag Features and Specifications

Once you’ve nailed down your audience’s needs, the next step is turning those insights into clear technical specifications. This includes details like the bag’s dimensions, weight capacity, material choices, hardware finishes, and branding elements such as embossed logos. For example, a hiking bag designed to carry up to 44 lbs (20 kg) requires stronger reinforcements than a student backpack meant for lighter loads of around 11 lbs (5 kg). Tool bags, on the other hand, may need bar-tack stitching and impact-resistant materials. Providing manufacturers with precise details – such as Pantone color codes and high-resolution logo files – can significantly speed up the development process.

Striking the right balance between weight, storage capacity, durability, and style is key. One way to catch potential design flaws early is by creating a simple paper model. This allows you to test the bag’s shape, size, and functionality before committing to expensive prototypes, saving time and money in the long run.

"The best designs often come from those who are designing for their own needs and wants. After all, if you like it there will be other people who like it too." – nobrand custom

Step 2: Sketching and Digital Design

Now that you’ve nailed down your concept and detailed specifications, it’s time to transform those ideas into a visual reality. This stage bridges the gap between abstract concepts and the tangible prototypes that will eventually bring your bag design to life. It all starts with quick hand sketches before progressing to precise digital files ready for manufacturing.

Creating Hand Sketches and Technical Drawings

Hand sketching is a fast and flexible way to explore various shapes, sizes, and design details without diving into costly digital tools right away. These quick sketches allow you to experiment with different configurations and refine your ideas. Once you’ve settled on a direction, the next step is to create fashion flats – clean, black-and-white technical sketches that show your bag from multiple perspectives, such as front, back, and side views.

Be sure to include all the interior details, such as lining, pocket placements, and stitching patterns, to fully communicate your design. Add callouts specifying measurements, hardware placements (like zippers, buckles, and D-rings), and construction details. Standard seam allowances typically range from 1/4" to 5/8" (5 mm to 1.5 cm). If you’re planning multiple color options, create separate sketches for each version and include their corresponding Pantone codes.

"Technical sketches (also called fashion flats) represent the idea of what a handbag has to look like when produced. Fashion flats should illustrate every design detail from different angles." – Techpacker

Before moving on to digital tools, consider making a simple paper model based on your technical drawings. This inexpensive step helps you check the scale and functionality of your design, potentially catching issues before investing in costly prototypes, which can range from $200 to $450. Once you’re confident in your sketches, it’s time to move to digital design tools for greater precision.

Using CAD Software for Prototyping

Digital tools take your hand sketches to the next level, allowing you to refine your design into accurate, scalable blueprints perfect for manufacturing. For instance, Adobe Illustrator is a go-to for creating vector-based fashion flats, and its "Recolor Artwork" feature makes testing different color schemes a breeze. Meanwhile, Adobe Photoshop is ideal for adding textures and creating realistic pattern previews.

For more advanced needs, 3D simulation software like CLO Virtual Fashion und Optitex lets you see how fabrics will drape and behave on your bag design – without wasting materials. If your project involves precise component fits, Rhino offers high-accuracy modeling, while Romans CAD 2D BAG specializes in pattern nesting to optimize material usage and reduce waste. With these tools, some manufacturers can even deliver a first prototype in as little as 3 to 5 days.

Another advantage of CAD systems is the ability to create a "digital twin" of your bag – a comprehensive file that documents dimensions, materials, and construction details all in one place. This level of precision reduces sampling errors and ensures that everyone involved, from pattern makers to factory workers, is working from the same blueprint. At JUNYUAN BAGS (https://junyuanbags.com), we use these digital tools to streamline the design process, saving both time and resources.

| Software Tool | Primary Use | Key Benefit |

|---|---|---|

| Adobe Illustrator | Creating scalable fashion flats | Easy color and pattern testing |

| Adobe Photoshop | Adding textures | Realistic visualization of fabrics |

| CLO Virtual Fashion | 3D fabric simulation | Visualizes drape without waste |

| Optitex | 2D/3D pattern making | Reduces need for physical samples |

| Romans CAD 2D BAG | Pattern nesting | Maximizes material efficiency |

Step 3: Technical Pack and Pattern Development

This step is all about turning your digital design into something that can actually be manufactured. Think of it as creating a detailed blueprint that ensures your design stays true to its original vision during production. The technical pack, often called a "tech pack", acts as both a guide and a binding agreement between you and the factory. It spells out everything – measurements, materials, construction methods – essentially serving as your design’s instruction manual.

Building a Technical Pack

At its core, a tech pack is a document that captures every agreed-upon detail, making the production process much smoother. And the numbers don’t lie: brands that use tech packs reach production after just two rounds of sampling on average, compared to 4.5 rounds for those who skip this step. This efficiency can save you anywhere from $360 to $900 per design during sampling alone.

"Think of a tech pack like a legal contract – it outlines the specific nature of the product you wish to be manufactured and ensures all specifications are met." – White2Label Manufacturing

A complete tech pack should include:

- Technical sketches: These should cover all views – front, back, side, base, and interior – to clarify details like lining, compartments, and pockets.

- Bill of Materials (BOM): This lists every component, from fabrics and linings to hardware (with sizes, finishes, and supplier codes), thread types, and even packaging materials.

- Measurement specs: Include dimensions like height, width, depth, gusset size, and strap lengths, along with tolerances (±0.2" or ±0.5 cm).

- Construction details: Specify stitch types, stitches per inch (SPI), edge treatments (like burnishing or skiving), and reinforcement placements. Use Pantone codes for fabric and hardware colors to avoid confusion.

The industry is moving away from static Excel spreadsheets toward cloud-based tools like Techpacker and Onbrand PLM. These platforms allow for real-time collaboration and version control, speeding up tech pack creation by 55% and cutting product development cycles by about four weeks. At JUNYUAN BAGS, we rely on these modern tools to ensure every design detail is documented with precision.

Once your tech pack is complete, the next step is to translate it into accurate 2D patterns for production.

Pattern Creation and Material Efficiency

With your tech pack in hand, pattern makers create detailed 2D templates. These flat patterns are the foundation for crafting your three-dimensional bag. Using computer-aided design (CAD) systems for this process ensures precision, symmetry, and fewer errors, which ultimately speeds up development. Each pattern piece should be clearly labeled with its name, size, cutting instructions, and the number of pieces needed.

Before committing to expensive materials like leather, it’s wise to test your design with a cardboard mock-up. This step lets you confirm that the 2D pattern translates correctly into a 3D shape without wasting costly resources. Additionally, patterns should account for stress points by including reinforcements, such as bar tacks or box-X stitches, in the technical drawings.

Efficient patterns also reduce fabric waste. By carefully arranging pieces (a process called nesting), you can optimize material usage, cutting costs and reducing waste. For mass production, precise 2D patterns ensure clean cuts and consistent tolerances. Even minor deviations – just a few millimeters – can alter a bag’s final silhouette, so experienced factories use sharp blades and enforce strict cutting standards.

| Tech Pack Component | Role in Efficiency/Accuracy |

|---|---|

| Technical Sketches | Provides clear visual guidance to prevent construction errors. |

| Bill of Materials (BOM) | Ensures all components are accounted for, reducing waste and tracking costs. |

| Measurement Specs | Defines dimensions and tolerances for consistent production. |

| Construction Details | Specifies stitch types, SPI, and reinforcements for structural integrity. |

Step 4: Material Sourcing and Prototype Construction

Once your tech pack is ready, the next step is to source materials and create your first prototype. This is where your design starts to take shape – literally. You’ll move from sketches and plans to something tangible that you can test, tweak, and refine. Materials typically account for about 30% to 40% of the total cost of your bag, while hardware like zippers and buckles adds another 10% to 15%. These percentages help guide your decisions when selecting materials and components.

Selecting Materials and Components

Begin by putting together a detailed bill of materials (BOM). This list should include everything you’ll need: shell fabric, lining, foam, webbing, thread, labels, and hardware like zippers, buckles, and D-rings. The fabric you choose plays a huge role in determining the bag’s overall performance. For example, nylon is incredibly strong and resistant to abrasion, making it perfect for outdoor or tactical bags. On the other hand, polyester is a more budget-friendly option and offers better color retention, which works well for everyday backpacks. If eco-friendliness is a priority for your brand, consider recycled materials like RPET (recycled polyester) or recycled nylon. These options meet compliance standards such as GRS and OEKO-TEX.

"Material selection determines a bag’s strength, durability, weight, sustainability profile, and final cost." – Meyzy

Hardware is just as important as the fabric. Using reliable, branded components like YKK oder SBS zippers and Duraflex buckles ensures durability and smooth functionality. High-quality hardware reduces the risk of failures, which can be costly to fix down the line. To keep costs in check, try consolidating your trim colors and specifications across different bag models. For instance, using the same zipper color or webbing type can help you meet supplier minimum order quantities (MOQs) and secure better pricing.

Before committing to expensive materials like leather, which can cost around $26 per square meter, request a line-item BOM. This breakdown will show you exactly where your money is going – covering everything from shell fabric and lining to hardware brands and even scrap rates. It’s a great way to spot hidden costs or avoid low-quality substitutions. At JUNYUAN BAGS, for example, we provide transparent BOMs and work with clients to balance material quality with budget limitations, ensuring you don’t compromise on durability or design. These early decisions lay the groundwork for a strong prototype.

Building the First Prototype

Start by creating a paper or muslin mockup to verify dimensions and functionality. This simple step can help you catch sizing errors early, saving you from costly adjustments later.

When assembling the prototype, follow a step-by-step process: begin with pockets, then move on to the main body, reinforcements, binding, and final assembly. Pay special attention to load-bearing areas like strap attachments. Reinforce these spots with bar tacks, box-X stitches, or additional webbing to ensure durability. Next, add hardware like zippers, making sure they glide smoothly, and test straps to confirm they adjust easily. Foam padding should be evenly placed without bunching.

Prototyping costs can range from $500 to $1,000 and typically takes 7–14 days. However, factories with in-house prototyping teams can sometimes complete the process in just 3–5 days. The final steps – trimming loose threads, cleaning up edges, and pressing the bag into shape – bring everything together. Once your prototype meets your standards, it becomes your "Golden Sample", setting the benchmark for all future production units.

sbb-itb-1e6451b

Step 5: Sampling, Testing, and Iteration

After finalizing your design specifications, the next step is to ensure your bag meets all performance standards. This is where testing comes in. It’s the stage that determines whether a design that looks great on paper can actually hold up in real-world use. By identifying potential issues with durability, functionality, or construction early on, you can make adjustments before committing to large-scale production – saving both time and money.

Testing Prototypes for Quality

Start with load testing to confirm your bag can handle the weight it’s designed for. For larger bags, load them to their maximum rated weight (e.g., 50 lbs), lift them 20 times, and hang them for four hours to check for any damage. Next, simulate sudden force by performing a jerk test: drop half the rated weight five times from a height equal to half or three-quarters of the handle length. This mimics scenarios like pulling a bag off a luggage carousel.

"A solid-made bag is typically manufactured to carry more than the maximum load printed on the rating label." – Stacy Bruce, InTouch Quality

Test fasteners like zippers, buttons, and Velcro by cycling them 50 times to ensure they hold up under repeated use. Shoulder straps and buckles should undergo abuse testing – apply about 20 lbs of force for 10 seconds using a tension gauge. For overall durability, try an item drop test: load the bag with roughly 55 lbs (25 kg) and drop it from a height of one meter onto all six sides. This simulates the wear and tear bags experience during transit or daily use.

Additionally, conduct material-specific tests for shrinkage, pilling, tensile strength, colorfastness, and abrasion resistance. If you’re selling through retail channels, plan for compliance testing, such as REACH or Prop 65 chemical spot panels, which cost $120–$250 per style. Colorfastness and abrasion tests typically range between $25 and $80 per test route. These tests not only ensure quality but also help you meet industry standards.

The insights you gain from these tests are invaluable for refining your design.

Refining Designs and Managing Costs

Once testing is complete, use the results to fine-tune your design. For instance, if a strap attachment fails during jerk testing, reinforce it with bar tacks or box‑X stitches. If a zipper jams during fatigue testing, consider upgrading to more reliable hardware like YKK or SBS zippers. Feedback from manufacturers, retailers, and even end users can also provide valuable input. Compare different prototype versions side-by-side and use structured feedback methods – such as "I Like, I Wish, What If" – to turn general observations into actionable improvements.

Sampling costs can vary widely, from $150–$350 for standard designs to $500–$1,000 for more complex prototypes. The development process typically takes 3–5 weeks, though experienced factories may deliver in as little as 7–14 days. Addressing flaws during the sampling phase is far more cost-effective than fixing them during mass production.

Once all feedback and test results have been incorporated, finalize your prototype as the definitive sample. This sample becomes the benchmark for mass production, ensuring consistency and preventing quality variations across units. At JUNYUAN BAGS, we create multiple definitive samples – one for our production team, one for third-party inspectors, and one for client reference. This approach guarantees every bag meets the approved specifications and maintains the highest quality standards.

Step 6: Design for Manufacturing and Final Approval

With your refined prototype ready, the next step is transforming it into a design optimized for mass production. This stage shifts your handcrafted sample into a consistent, scalable product. By focusing on the details of production, you ensure a smooth transition from prototype to final product.

Applying Design for Manufacturing (DFM) Principles

Design for Manufacturing (DFM) focuses on making products easier and more cost-efficient to produce while preserving quality. Start by simplifying your design – reduce the number of parts and eliminate unnecessary features. For instance, if your bag design includes five pockets, consider whether three could achieve the same functionality while lowering labor costs.

Standardizing components is another key step. Use off-the-shelf hardware whenever possible to cut lead times and expenses. While custom parts may look appealing, they often add significant costs to your materials budget. Additionally, consolidate parts by designing multi-functional components. For example, a structural panel could double as padding.

"At its core, DFM is the practice of designing products with production in mind, aiming to minimize difficulties and expenses associated with manufacturing processes." – Tencom Ltd.

Collaborate with your manufacturing team early to address potential production challenges. If your production is overseas, hiring a sourcing agent can help navigate language barriers and negotiate terms effectively. Also, design for efficient assembly – ensure your bag can be put together quickly and accurately. Adjustments made during this phase are critical for a seamless production process.

Final Quality Checks and Approval

Once the design is optimized for manufacturing, every detail must be validated. The final approved sample, often called the "gold sample", becomes the benchmark for all mass-produced units.

"At the end of the sampling process you will get what it is commonly called a ‘gold sample’. This is the sample against which every unit of the product will be measured so it needs to be checked to the minimum detail." – Ollie Tigwell, Design2Market

Conduct detailed inspections to ensure dimensional accuracy (within 0.3 cm) and verify the functionality of all components. For international exports, confirm compliance with chemical standards like REACH for restricted substances. Request a pre-production (PP) sample, which is created on the actual production line. These samples help identify any discrepancies between the handmade prototype and the factory-produced version.

Establish clear Standard Operating Procedures (SOPs) for assembly, covering details like needle type, stitch length, and tension settings. Reinforce stress points using bar tacks, box-X stitches, or extra webbing layers to ensure durability. At JUNYUAN BAGS, for example, a four-stage inspection process – Incoming Quality Control (IQC), In-Process Quality Control (IPQC), Final Quality Control (FQC), and Outgoing Quality Control (OQC) – is used to maintain consistency from raw materials to finished products. These steps ensure that the mass-produced units match the quality of the approved prototype. Once your gold sample clears all inspections and gains stakeholder approval, you’re ready to move confidently into full-scale production.

Common Challenges and Solutions

Developing bag samples can come with its fair share of hurdles, from delays to unexpected costs. Tackling these challenges head-on is key to keeping your project on track and within budget.

Communication gaps are a common culprit behind errors. Misunderstandings about measurements, stitching details, or color specifications often result in incorrect samples. Elaine Zhou, Business Director at Shanghai Fumao, highlights this issue:

"Communication gaps are the biggest cause of problems in sample development."

The solution? Comprehensive tech packs. These should include exact measurements, detailed construction instructions, and reference images. Regular updates and clear communication with your manufacturer can catch potential issues before they snowball.

Material sourcing delays can wreak havoc on timelines, especially when rare fabrics or custom components are needed at the last minute. To avoid this, work with manufacturers who have reliable and certified supplier networks, like JUNYUAN BAGS. Such partnerships ensure steady material availability and quicker restocking cycles.

Sample-to-production discrepancies are another headache. Sometimes, the final product doesn’t match the approved sample due to differences in machine settings, operator skills, or production processes. To bridge this gap, request a pre-production sample made on the actual production line, not just in the sample room. Additionally, establish a "Golden Sample" as your quality standard. Billy Miner from Insight Quality Services explains:

"A Golden Sample… represents a perfectly-made product that completely aligns with your product quality standards."

Here’s a quick breakdown of common challenges, their impacts, and how to address them:

Table: Challenges, Impacts, and Solutions

| Challenge | Impact on Timeline & Cost | Resolution Strategy |

|---|---|---|

| Material Sourcing Delays | Delays production; increases costs for rare materials. | Use certified supplier networks for consistent material supply. |

| Inconsistent QC Standards | Leads to stitching defects and product rejections. | Perform inspections at every stage (IQC, IPQC, FQC, OQC) and use a Golden Sample. |

| Technical Errors in Tech Packs | Results in multiple rounds of re-sampling, driving up costs. | Work with professional designers to create detailed CAD drawings and specs. |

| Sample vs. Production Variance | Final product differs from the approved sample. | Use standardized SOPs and ensure production-line samples match prototypes. |

| Skilled Labor Shortage | Inconsistent quality in stitching and assembly. | Partner with manufacturers who invest in training and standardized sewing SOPs. |

Schlussfolgerung

Turning your bag concept into a tangible product involves a meticulous process, where each step builds on the last. From the initial research phase to quality approval, the journey transforms rough sketches into prototypes designed to hold up under real-world conditions. Prototyping plays a critical role in confirming design decisions, while rigorous testing ensures consistent production standards.

This entire process thrives on collaboration. As nobrand custom aptly states:

"The prototyping process should be a partnership where the manufacturer uses its deep knowledge and expertise to help you improve and realise your item".

Without this collaborative effort, challenges like delays, quality issues, and expensive rework can quickly arise. At JUNYUAN BAGS, this partnership is at the heart of what we do.

JUNYUAN-TASCHEN supports your journey from concept to market-ready product. With over 20 years of expertise, we specialize in delivering fast 3D Tech Packs and prototypes. Our 8,000‑m² facility, equipped with six production lines, produces between 200,000 and 250,000 pieces monthly. We also hold internationally recognized certifications such as BSCI, ISO 9001, and REACH. This streamlined approach ensures that every bag meets the strict quality standards outlined throughout the process.

Whether you’re launching a new sports bag collection, customizing travel gear, or designing specialized Werkzeugtaschen, we offer comprehensive services. These include design consultations, material sourcing through a nationwide supplier network, sample creation, and global shipping. With over 5,000 custom projects completed for brands in 30 countries, we provide flexible minimum order quantities starting at just 50 units for test orders.

FAQs

What are the main advantages of creating a tech pack for bag sample development?

Creating a tech pack is a key step in bringing your bag design to life. Think of it as the ultimate guide that bridges your vision with the manufacturer’s execution. It lays out every detail of your design, leaving little room for miscommunication or costly mistakes during production.

With precise specifications, a tech pack helps keep production on track, ensures consistent quality, and provides a clearer picture of costs upfront. It’s the tool that takes your idea from concept to a polished bag prototype with fewer hiccups along the way.

How can I choose the best materials for my bag prototype?

Choosing the right materials for a bag prototype starts with understanding its intended use. Will it need to carry heavy loads, endure tough weather conditions, or simply look stylish? For strength and durability, nylon is a solid choice for heavy-duty or travel bags. On the other hand, polyester is lightweight, water-resistant, and budget-friendly, making it a great option for gym or casual backpacks. If style is a priority, you might lean toward natural fabrics like cotton canvas oder Leder, though these may require a water-repellent finish to enhance their functionality.

When prototyping, consider using affordable substitutes that closely mimic the final material. This allows you to test key design aspects like fit, stitching, and hardware placement without overspending. For instance, 600D nylon is a reliable choice for heavy-duty prototypes, while a 10 oz cotton canvas works well for more fashion-oriented designs. Keeping costs manageable is crucial, with prototype expenses often ranging from $500 to $1,000 for more intricate bag designs.

Lastly, don’t overlook sustainability and branding. If eco-consciousness is a priority, materials like recycled PET oder reclaimed cotton are excellent options. Make sure your chosen fabric is compatible with your decoration method – whether it’s embroidery, screen printing, or another technique – so your prototype captures the essence of the final product.

How is a bag tested to ensure it’s durable and functional?

To ensure a bag can stand up to daily use while staying practical, manufacturers put it through a series of rigorous tests. Tensile-strength tests are conducted on stitching, straps, zippers, and hardware to confirm they can handle stress and regular wear without giving out. Simulated real-life scenarios, like load testing und drop or vibration tests, check the bag’s ability to handle heavy weights and sudden impacts.

For wet conditions, water-resistance tests are performed using pressure, spray, or even submersion methods to make sure the bag keeps its contents dry. On top of that, closures, zippers, and other components are carefully tested to ensure they work smoothly and hold up under frequent use. These steps guarantee the bag is built to last and performs reliably across a variety of situations.

Mobile/What's App/Wechat

Mobile/What's App/Wechat E-Mail

E-Mail ADD

ADD